.jpg)

Extrusion cooking involves the application of mechanical energy supplied by the shearing and mixing action of the extruder screws. Photo courtesy of Clextral. During the process, a formula mix is transformed from a powdery, free-flowing meal into a dense, compact powder.

.jpg)

Twin-screw extrusion provides the ultimate flexibility in process and recipe control to produce the broadest range of micro aquafeed products without the need for changes in mechanical components or configuration – resulting in increased uptime.

Oct 1, 2023 · Abstract. An empirical model was applied to quantitatively model the effects of extrusion variables and recipe compositions on quality of feed pellets. Lab extrusion trials were performed with an Atlantic salmon feed recipe with using a central component design (CCD).

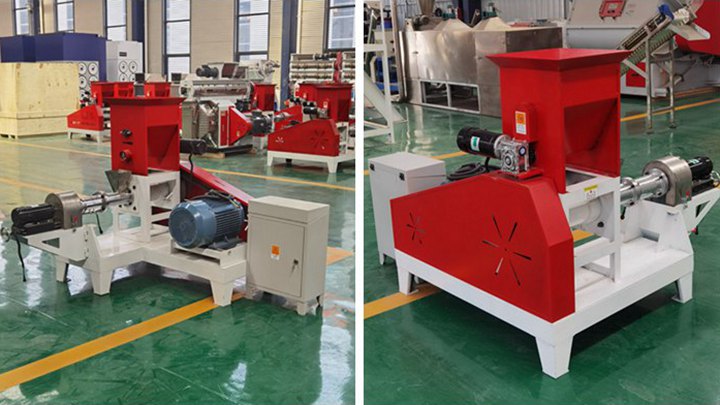

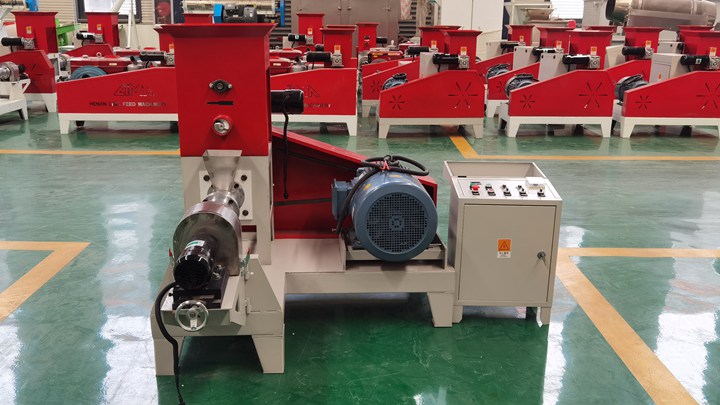

Aqua Feed Extruder SPHS-S Series Double-Screw Wet Extruder . Suitable for high - grade floating or sinking aquatic feed, food, pet feed, especially for viscous formula.

Apr 1, 2001 · The two major approaches to aquatic feed processing are pelleting and extrusion. Each method offers benefits and advantages. Fig. 2: Major components of a wet extrusion system. Pelleted feeds. Advanced pelleting systems are capable of delivering durable, water-stable particles that increase feed efficiency.

.jpg)

The key to producing quality aqua feed without losing essential nutrients is a gentle extrusion process. Our extrusion solutions give you precise control over the cooking and shaping process so that you can produce fish feed of the highest quality.

.jpg)

There are two kinds of extruders that might be used in aquafeed production: the single-screw extruder and the twin- screw extruder. Single-screw extruder: As its name implies, a single-screw extruder has only one extruding screw and is of simple structure, so its price is relatively lower.