Application: Fish oil,Fishmeal,Soya protein,Wheat gluten,Wheat and peas, etc. pellet dia: 0.9-10mm. customized. 60-5000kg/h. 1 year. Make feed pellets for all kinds of fishes, suitable for fish pond holders and feed pellet manufacturers. 200-300kg/h Small Feed Pellet Line. Get Free Quote!

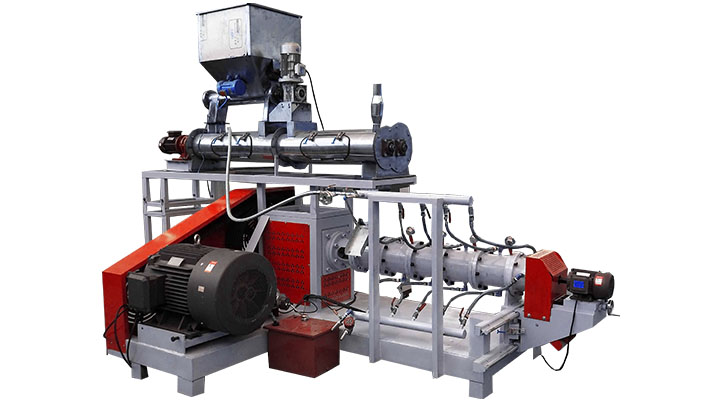

450-500kg/h Feed Pellet Plant Introduction This small feed pellet plant also called feed pellet production line, feed pellet plant, cattle feed plant, poultry feed plant, feed mill plant for poultry, it is specially designed for produced animal feed pellet. It can produce 500kg feed pellet per hour.

.jpg)

MIKIM Cattle Poultry Pet Feed Production Line Pellet Plant 1.5t/ H 0.8t/ H Feed Manufacturing Machine Pet Feed Production Line Cattle feed pellet plant, flat die animal feed pellet production line include crusher, mixer machine, pellet machine , cooler and conveyors.

800~1000Kg/h Chicken Feed Pellet Plant Business in Botswana Recently, a customer planning to set up his own poultry feed farm in Botswana consultedLima Machinery about the business plan and the required equipment and purchased a complete feed line of 800 ~1000 kg/h, including a grinder, mixer, pellet mill, cooler and two auxiliary units (conveyor and buffer bin) .

Total 220kw Feed Pellet Production Line With SKF Bearing Capacity 10T/H. Line name:Large Feed Factory Use Feed Pellet Production Line With SKF Bearing. Application:Animal Husbandry factory. Total power:550kw. Pellet size:0.9-15mm

.jpg)

150 Kg Per Hour Expanded Fish Feed Production Line for Ponds Arrived in Bolivia; 800~1000Kg/h Chicken Feed Pellet Plant Business in Botswana; Feed Pellet Mill Delivered to Chicken Farm in Afghanistan; 1-2TPH Chicken Powder Feed Pellet Equipment Deliver to Kenya; 5TPH Animal Feed Pellet Making Machine Arrives in Indonesia

.jpg)

List offish-pellets Manufacturers serving Botswana. MET MANN enjoys more than 40 years experience in air-conditioning and air treatment products manufacture and marketing.

The customer came to the factory and our sales and engineers designed the most suitable solution for them until one o'clock in the evening. Finally, they decided on the 10T/H Complete Feed Pellet Production Line. What's more,we can construct many other feed production line,such as livestock,poultry, acqua, prawn and premix, at various scales.

Feature of smallfish pellet plant: 1.can realize one-stop operation with electric cabinet control. 5.Able to change new die and rollers fast and conveniently. 6.Simple structure, small area coverage, easy operation and maintenance.

.jpg)

Feature of smallfish pellet plant: 1.can realize one-stop operation with electric cabinet control. 5.Able to change new die and rollers fast and conveniently. 6.Simple structure, small area coverage, easy operation and maintenance.

pellet mills pellet mills Companies serving Botswana Serving Botswana Near Botswana Premium JSC Radviliskis Machine Factory based in Radviliskis, LITHUANIA JSC “Radviliskis Machine Factory” was established in 1949. It is the only factory in Baltic states which designs and produces equipment for pellets production.

.jpg)

Complete Process For Pellet Line. Based on different materials, we have suitable pellet lines. The whole process include Material Crushing Section, Drying Section, Pelletizing Section, Pellets Cooling Section and Pellets Packing Section. The production capacity can be 500kgs/h to max 20ton/h, below is our project we customized for our customers

Poultry feed pellet production line Introduce: Poultry feed pellet production line is specialized in making animal feed pellet for chicken, pig, duck, goose, fish, sheep, cattle, horse, deer etc. They can process almost all kinds of raw materials for feed manufacturing, such as grain or grass.

What is Botswana Best Sale Animal Poultry Chicken Feed Pellet Production Line, Feed Unit manufacturers & suppliers on Video Channel of LimaFeedPelletizer.com.

.jpg)

Small Scale Poultry Feed Mill Pellet Production Line. 1. Complete poultry feed pellet line process: raw material receiving and cleaning, crushing, mixing,pelletizing, pellet cooling&screening, pellet packing. 2. We can equip full line according to your actual needs. 3. Engineers available for installation and training.