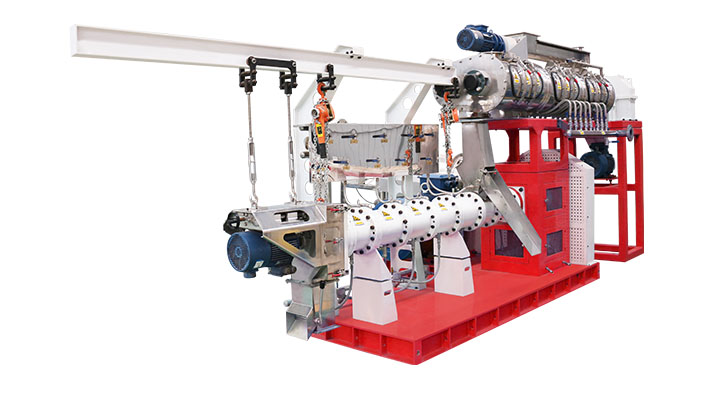

Description Description 2-4T/H Ring Die Feed Pellet Production Line The SZLH320 ring die feed pellet production line is one of our company’s animal feed pellet production lines. The capacity can be 2t/h-4t/h.It is your good choice if you want to build a feed pellet factory.

Aug 25, 2018 · 3.The farm-use one has simpler structure, lower price and maintenance cost than the industrial-use one, so it is a good choice for users that have limited investment budget. 4.The pellet produced by the farm-use one has a diameter of 1.5-12mm, and the pellet produced by the industrial-use one is 2-10mm, so the farm-use one can meet a wide

.jpg)

The feed materials are involved between the ring die and roller, two relatively rotating parts squeeze them into ring die holes. Feed pellets form in the mold holes, and are squeezed out of the holes’ outer ends. The pellets are cut into required length by the cutting knife. Ring Die Feed Pellet Mill Technical Parameter

.jpg)

Search for used cattle ring die feed pellet production line. Find Luodate and Eternalwin for sale on Machinio.

Oct 16, 2018 · Pelletizing is a key process to the production of high quality poultry feeds as it ensures that the feed formulation with rich nutrition and in the correct quantities for poultry. Each bite of a pellet made by our ring die poultry feed pellet machine will have the same quality to improve the animal performance. ★ Improved animal performance

.jpg)

Feed Pellet Machine. SZLH Series Ring Die Pellet Mill 9KLHC Series Ring Die Pellet Mill 9KLH Series Ring Die Pellet Mill 500-1000KG/H Feed Pellet Production Line; Flat Die Pellet Machine. 90-400KG/H smallfish pellet machine 200-400KG/H small animal feed pellet machine 300-500KG/H small animal feed pellet machine 400-600KG/H small animal feed

Since ring die pellet machine usually has big production capacity, so the ring die pellet machine line is usually for the large scale feed orfish pellet plant. the capacity is from 1TH to 20T/H. Thefish pellet production line includes the process of crushing, drying, pelletizing, conveying, cooling and packing. The feed pellet line has the

.jpg)

The feed pellet mill is equipped with stainless steel feeder and Denmark original imported Danfoss inverter contorl to guarantee accurate and reliable material feeding. It adopts fully stainless steel conditioner and large open access door for convenient maintenance. Inside the conditioner, there are Food Grade 304 Stainless Steel paddles and

Hkj250 Ring Die Small Feed Pellet Making Line. we have sucessfully experience on making coffee pellet from coffee husk,coffee waste ground,coffee skin.we can provide complete coffee pellet production line

.jpg)

Dec 02, 2019 · Get Price Now! First, the ring die feed pellet machine. The ring die feed pellet machine’s hourly output is larger than the flat die feed pellet machine, generally between 0.5 tons-15 tons. Often used in conjunction with a variety of large and medium pellet units. Our common large-scale cattle and sheep feed pellet unit is the matching ring

.jpg)

Mar 07, 2019 · As the name suggests, the ring die feed pellet mill has a wide cylindrical shape die and is mounted vertically. It mainly consists of feeding device, hardening and tempering device, conditioner device, press chamber transmission system, overload protection and electric control system. Featured with high throughput, nice pellet forming shape, high density and low consumption, ring die feed pellet mill is widely adopted in most large scale feed pellet production line.

2.1 The feed pellet production line has a small footprint and a high degree of automation. 2.2 It produces smooth and hard particles suitable for a variety of animals. 2.3 The pellets are very nutritious and can meet the growing needs of animals. 2.4 This production line is widely used in medium and large feed plants.

After carburizing and quenching treatment, the die hardness is 55-60HRC, The working life of a flat die is 300-500 hours. When one side has worn out, the die can be used with the other side. And the output of a ring die is 5000-8000 ton, it should be repaired with the die repair machine in the factory. 1. Pellet mill die material.

.jpg)

Ring die feed pellet mill is widely used in the granulation of corn, wheat, beans etc. The output pellets are used as animal and poultry feedstuff in livestock farm, poultry farm, feed processing industry and aquaculture. Now, based on the outstanding features of its high throughput, low consumption and mature technology, ring die feed pellet mill has become more and more popular and possess broad market share at home and aboard.

Ring die pellet machine, widely used in large, medium and small-scale aquaculture, grain feed mills, livestock farms, poultry farms, individual farmers and small and medium farms, or large, medium and small feed mills use . Ring die pellet machine advantages: 1. Material dry-in and dry-out, compressed into pellets, it is more conducive to