.jpg)

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

Feed pellet line which can produce 3000-10000 T powder materials or feed pellets per year. The complete pelletizing process includes raw material receiving, crushing, batching, drying, feed pelleting and packaging. During milling, the nutrition of feed pellets will not lose. Technical Parameters of small feed production line.

.jpg)

Nov 27, 2020 · A snowing day of the end January in 2020, two customers from Zimbabwe came to our factory to see the feed pellet production line which they planed to purchase. After previous four months’ communication about the machinery description, quotation and so on, customer were very interested in our feed processing equipment.

AMSPLM-200B Electric Feed Flat Die Pellet Mill is an ideal pelletizing machine mainly used for small-scale production of animal and poultry feed pellets, grain feed factory, farm, poultry farm. The raw materials are easy to obtain, like corn, maize, wheat bran, rice, beans, etc. Driven by electric motor makes it more energy-saving and environmental friendly.

.jpg)

Aug 25, 2018 · The feed pellet production line can be used to make various poultry feed and aquatic feed for rabbits, ducks, cattle, chickens, sheep, pigs, pigeons, fishes and shrimp etc. The whole production line can be control by the automatic PLC control system. The feed grinder can grind the raw material ingredients to the required size.

The SKJ series small pellet mill is one of our mainly products, it is also be called at flat die pellet mill, and the small machine operate easily, and suitablefor home use.It can be used for making fuel pellet, fertilizer pellet, and animal feed pellet.The output volume is high, energy consumption is low and the operation is convenient. For pellet making, the size of input materials should smaller than the diameter of the pellets you want to get. The best moisture content of raw materials

Because such pellet mill works on the base of the friction and pressure between the roller and the mounted die, flat die feed pellet machine is also known as flat die pellet press. Flat die pellet mill are the simplest design of animal feed pelletizer, this kind of manure pellet mill had been originally applied mainly in the animal feed market

This small animal feed pellet plant usually use the flat die pellet machine, because flat die machine cost less investment, cover small area, easy installation. This small line useually use KL300,KL400 machines.

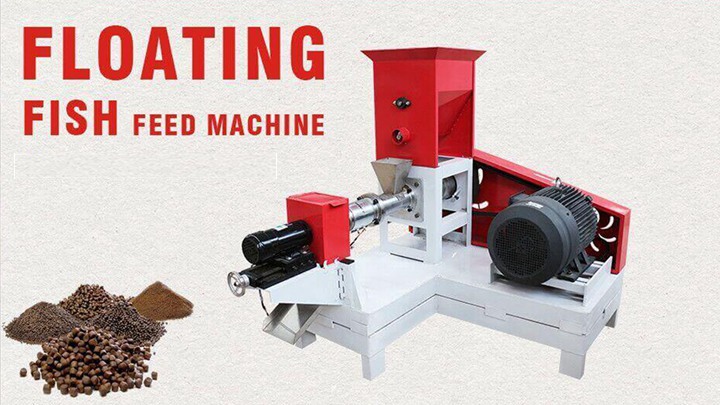

customized. 60-5000kg/h. 1 year. Make feed pellets for all kinds of fishes, suitable for fish pond holders and feed pellet manufacturers. 200-300kg/h Small Feed Pellet Line. Get Free Quote! 400-600kg/h Feed Pellet Production Line. Get Free Quote! 800-1000kg/h Feed Pellet Production Line.

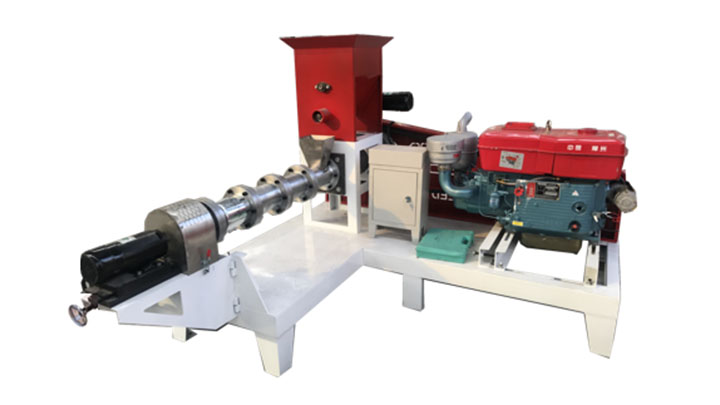

40. 685. 150*61*180. Small Flat Die Feed Pelleting Machine Introduction. This animal feed pellet making machine mainly used to produce the chicken, pig, rabbit, sinking fish poultry feed, and so on. The animal feed pellet machine is powered by electric or diesel engine, the diesel type can meet the place short of electricity.

.jpg)

This small feed pellets making line is specially designed for homemade pellet mill plans about manufacturing forage pellets for fish, sheep, cattle, rabbit, horse, chicken (such as hens in layer cage), duck, goose, pig and other livestock, etc. The diameter of feed pellets made by the feed pelletizer in this small feed pellet production line ranges from 2mm to 8mm.

.jpg)

This small feed pellet production line is specially designed for the production of feed pellets, which can produce fish, sheep, cattle, rabbits, horses, chickens, ducks, geese, pigs and other livestock feed pellets. The feed pellets produced by this small feed pellet production plant have a diameter between 2mm and 8mm.

The flat die pelletizer is a kind of extrusion machine, and it mainly depends on physical pressing strength to do the works. The common usage of the flat die extrusion granulator is to produce organic fertilizer pellets. But you can also apply it in the livestock feed production, or create somefish pellets with it.

The animal feed pellet market is growing fast with recent years, the flat die feed pellet machines are welcome in the breeding industry. The flat die feed pellet machine has the advantages of simple structure, covering a small areas, low cost, and low consumption.

.jpg)

Sep 01, 2016 · Features of Electric Flat Die Feed Pellet Mill. 1.Advanced technology employed, high quality and reasonable structure. 2.Driven by electric motor, which makes it more energy saving. 3.Low energy consumption, low noise and low failure rate. 4.Strong fatigue resistance makes continuous production possible, economic and durable.