The flat die pelletizer is a kind of extrusion machine, and it mainly depends on physical pressing strength to do the works. The common usage of the flat die extrusion granulator is to produce organic fertilizer pellets. But you can also apply it in the livestock feed production, or create somefish pellets with it.

This 1-2t/h chicken feed pellets line was built in Uganda. The client had raw materials of maize, soybean, soybean oil meal, sunflower seed oil cakes, pre-mix compound and fish powder. When producing chicken feed pellets, the particle material and powder material are fed into the feed mixer separately: particle materials are conveyed by the

5. Electric feed flat die pellet mill can process various kinds of solid grain into small feed pellets for animals like chicken, rabbit, pig, etc. 6.easy to transport, more tasty for animals 7.can make good feed pellets with smooth surface and appropriate hardness. Pellets-making Procedure with Flat Die Animal Feed Pellet Making Machine

.jpg)

Plant Location: Uganda. Production Output: Manufacturing 1~2 ton feed pellets per hour. Feed Formula: Soybean, soybean oil, soybean cake, sunflower cake, maize, wheat bran, fish meal and bone meal, premix. This animal feed production line is designed for making chicken feed pellets, located in Uganda. The basic info of the project is listed above.

Recently, one set of our poultry feed pellet making line has been set up in Uganda. Production Capacity: Produce 1~2 ton feed pellets per hour. Formula for Chicken Feed: Sunflower cake, soybean cake, soya, maize, fish meal, bone meal, soybean oil and premix. In order to meet the requirement of this Ugandan customer, we made the process design

This small animal feed pellet plant usually use the flat die pellet machine, because flat die machine cost less investment, cover small area, easy installation. This small line useually use KL300,KL400 machines.

.jpg)

200-300kg/h Small Feed Pellet Line. The 200-300kg/h feed pellet production line is developed especially for small farms. For your convenience, we provide this set of machine which includes only two processes, crushing and mixing process-pelletizing process. Screw conveyor connects the two processes. It’s easy and safe to operate at home.

A ring die chicken feed pellet machine is way more efficient as compared to a flat die feed pellet machine. This is also because a ring die type feed pellet machine is highly suitable for the production of quantity and quality chicken feed pellets. It has an in-built steam collection conditioner that mixes an cooks the materials hence providing

Flat Die Pellet Mill – Musa Body Machinery. 250400. 410450. 12206001000. raw materials in order to make pellets with the flat die pellet mill, the biomass materials should befish waste dust, sawdust, corn stalk, peanut shells, etc. thefish waste can be all kinds of raw materials, such as spruce tree waste, pine tree waste and other sawdust waste, tree branches and shavers or.

.jpg)

The modulators of the pellet machines used in the animal feed pellets manufacturing plant are all digital frequency controlled, which can precisely control the production yield. Poultry Feed Pellet Manufacturing Process. In the feeding section, the particle and powder raw materials are feed separately into the mixer.

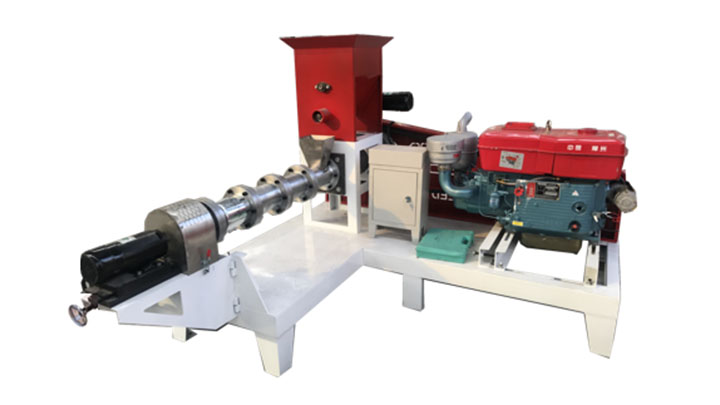

There are two types of small poultry feed pellet mill offered: electric feed pellet mill and diesel feed pellet mill. 1.Features and Advantages. (1) Simple structure and wide applicability. Cover small area and have low noise. (2) Roller and flat die are made from precise material of alloy steel, wear-resistant and not easy to break.

.jpg)

Want This Small Production Line,Get Price! This small feed pellet plant can produce 2~8mm of feed pellets with 500-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals.

Send Enquiry Now. Flat die pellet mill belongs to small pellet mill because of its capacity (under 800kg/h), it is applicable for makingfish, sawdust, straw, rice husk, bark, weeds, alfalfa, etc. into high density biomass pellets. The pellets are mainly used as fuel for home heating, central heating boiler, animal bedding, or as feed for poultry.

.jpg)

Jul 21, 2020 · Diesel flat die feed pellet machine, also known as diesel flat die feed pellet mill, which is used to produce feed pellet for livestock and poultry like pigs, chicken, cattle, rabbits, dogs, cats, etc. It can lower feed costs for medium-scale and small-scale farms dramatically. It creates features in terms of quality and perfect pelletizing

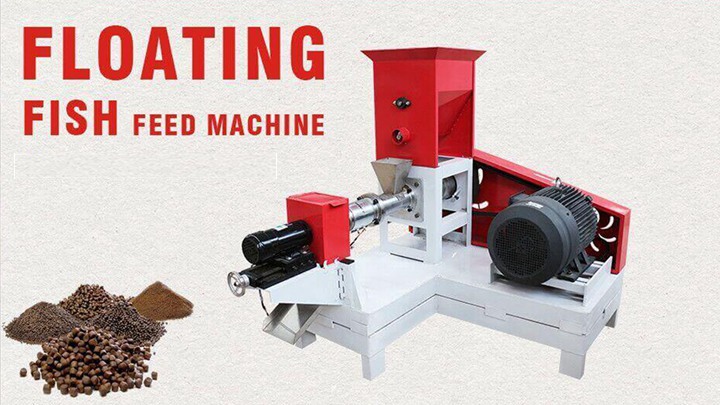

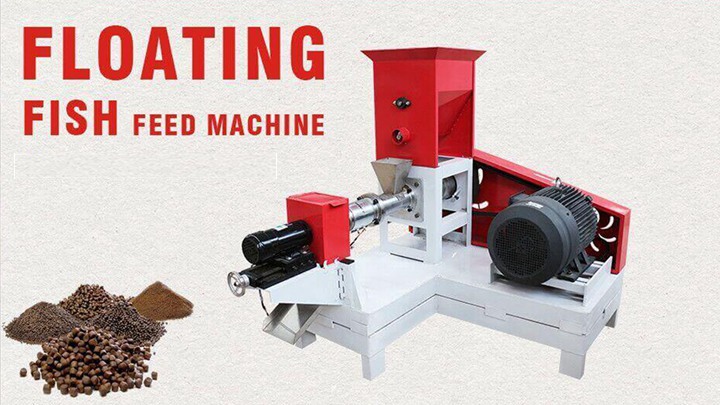

Small Ring Die Pellet Mill Bpm35. Designed with double belt driven structure. when the biomass raw materials enter the machine chamber by feeder, high speed rotating die will pressing the materials through the hole on the ring die. under high temperature and high forceful extrusion, density and smoothfish pellets will be shaped and fall out of the pellet machine.