.jpg)

Feed Pelletizer. The feed pelletizer in this small feed pellets production line has two types: ZLSP300B and ZLSP400B. The feed pellet mill machine presses feed mesh (like oil seeds meal, bone powders and corns, etc) to form pellets with uniform size (the same diameter and length). The feed pelletizer is a kind of flat die pellet mill and a good

How Does a Household Pellet Mill Work? In this article, detailed descriptions the structure of this pellet mill, the pelletiztion process, and how to buy a pellet mill. It is mainly consists of main feeder, roller, die etc. The pelletiztion process contain Raw Material Collect, Dry and Cle.

.jpg)

It can be used both sides, so the production cost is saved for users, since the flat die is a main wearing part in flat die poultry feed pellet mill. The symmetry of flat die determines it can be used both sides. 3.Roller characteristic. The features of flat die pellet machine roller are that it has low rotating speed and large diameter.

Jul 21, 2020 · Troubleshooting of Diesel Flat Die Feed Pellet Machine. 1. Low feed pellets production. ♦The first time a diesel flat die feed pelletizer is used with feed pellet produce. The production will increase after using several times. ♦Material moisture content is too high or too low. Adjust the material moisture content.

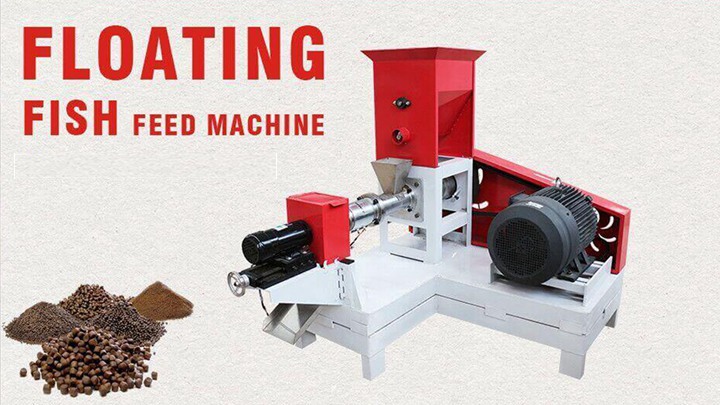

The flat die pelletizer is a kind of extrusion machine, and it mainly depends on physical pressing strength to do the works. The common usage of the flat die extrusion granulator is to produce organic fertilizer pellets. But you can also apply it in the livestock feed production, or create somefish pellets with it.

Flat die feed pellet mill is small scale feed pellet machine that is designed for small scale feed pellet production. Various power sources are available: electric motor, diesel engine, PTO, gasoline engine, you can choose according to your own needs. The feed pellet by flat die feed pellet machine can be adjusted into different size through different models of die diameters.

There are two types of small poultry feed pellet mill offered: electric feed pellet mill and diesel feed pellet mill. 1.Features and Advantages. (1) Simple structure and wide applicability. Cover small area and have low noise. (2) Roller and flat die are made from precise material of alloy steel, wear-resistant and not easy to break.

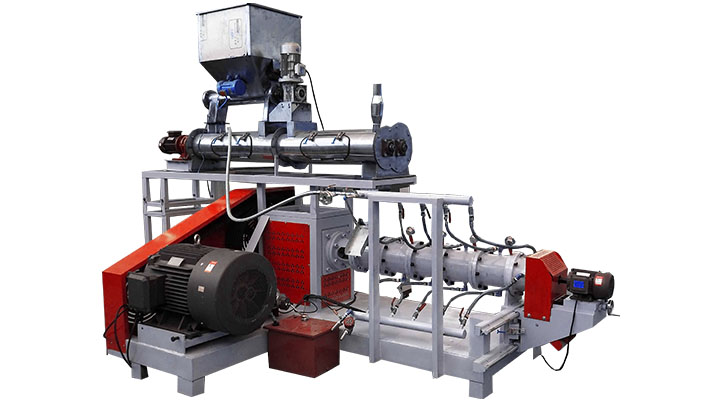

Feed pellet line which can produce 3000-10000 T powder materials or feed pellets per year. The complete pelletizing process includes raw material receiving, crushing, batching, drying, feed pelleting and packaging. During milling, the nutrition of feed pellets will not lose. Technical Parameters of small feed production line.

.jpg)

1 t/h pellet feed production line In order to meet the needs of the majority of small and medium-sized farmers and feed producers, we have designed and developed a flat-die pellet feed production line with a capacity of 1 ton per hour, can. Whatsapp: 0086-13419860671. Wechat: 0086-13419860671. Tel: 0086-13419860671. Email: info@cnhengfu.cn.

.jpg)

Small flat die pellet feed line Key words: Hammer mill Vertical mixer Screw conveyor Pellet machine Features: Cheap price, simple structure, wide applicability, small space-occupancy, high efficiency. For use: This unit is the first choice for medium and small feed processing plants, breeding plants, etc.

Want This Small Production Line,Get Price! This small feed pellet plant can produce 2~8mm of feed pellets with 500-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals.

.jpg)

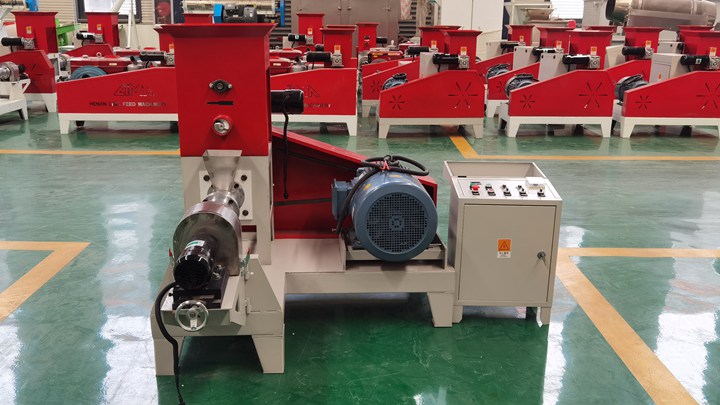

Flat Die Feed Pellet Mill. Dewatering Screw Press Machine. Fish Feed Extruder. Small Capacity Feed Pellet Production Line For Making Animal Feed / Fish Feed.

Flat Die Pellet Mill is a Popular Type of Pellet Mill for Sales on the Market: According to the power supply, there are 4 types of flat die pellet mills: electric pellet mill, diesel pellet mill, PTO pellet mill and gasoline pellet mill. Depending on the usage of pellets, flat die pellet mill can be divided into biomass pellet machine and

.jpg)

The complete small mobile feed pellet production line includes crushing, mixing, granulating, cooling, screening and packaging and conveying equipment. The process flow is complete and reasonable, and the adaptability is strong, which can meet the needs of different users. This product is suitable for processing feed into high-density granules.

3.Dry-processing, the production of feed pellet hardness and high, the surface is smooth, internal improvement, can improve digestion and absorption of nutrients. 4.Pellet produced in one process, without over size and recycling , pelletizing rate larger than 90%.