.jpg)

Flat Die Feed Pellet Mill Features and Application: 1. Driven by electric motor is more energy-saving and environmentally friendly. 2. Both the rollers and the flat die have passed wear-resistant process. The two sides of the flat die are exchangeable, which extends its service life and lowers cost. 3.

The complete small mobile feed pellet production line includes crushing, mixing, granulating, cooling, screening and packaging and conveying equipment. The process flow is complete and reasonable, and the adaptability is strong, which can meet the needs of different users. This product is suitable for processing feed into high-density granules.

.jpg)

The flat die pelletizer is a kind of extrusion machine, and it mainly depends on physical pressing strength to do the works. The common usage of the flat die extrusion granulator is to produce organic fertilizer pellets. But you can also apply it in the livestock feed production, or create somefish pellets with it.

.jpg)

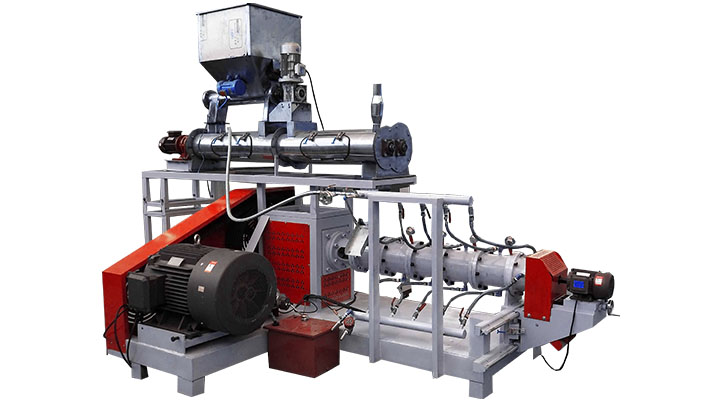

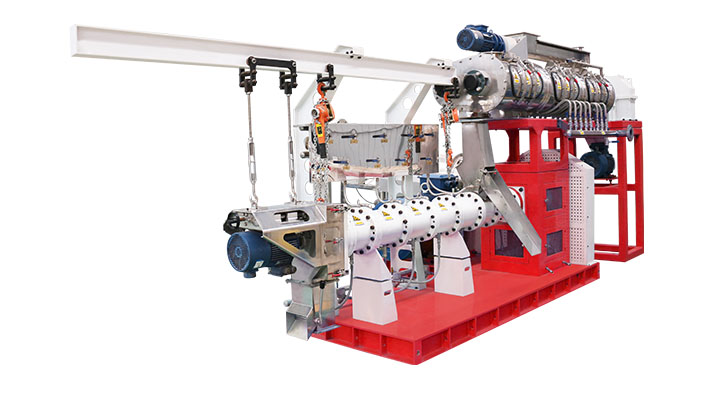

This animal feed producing line is used to process pellets of 1-12mm,the feed pellet plant is equipped with poultry fodder grinder&cow feed grinder*90KW,cow feed mixer machine&chicken fodder mixer machine*3500kg/batch,cattle animal feed pellet making line machine to make chicken feed*160kw,pellet cooler machine,pellet crumbler machine,screen machine,automatic packing machine and other equipment. In addition, according to the needs of customers and local actual conditions, we have configured

.jpg)

Want This Small Production Line,Get Price! This small feed pellet plant can produce 2~8mm of feed pellets with 500-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals.

Feed pellet line which can produce 3000-10000 T powder materials or feed pellets per year. The complete pelletizing process includes raw material receiving, crushing, batching, drying, feed pelleting and packaging. During milling, the nutrition of feed pellets will not lose. Technical Parameters of small feed production line.

.jpg)

Sep 01, 2016 · Features of Electric Flat Die Feed Pellet Mill. 1.Advanced technology employed, high quality and reasonable structure. 2.Driven by electric motor, which makes it more energy saving. 3.Low energy consumption, low noise and low failure rate. 4.Strong fatigue resistance makes continuous production possible, economic and durable.

The 15-16 tons per hour animal feed processing plant for cattle & poultry is planned to be divided into two parts. One part is for cattle feed production (5-6t/h), and the other part is for chicken feed production(10t/h).

.jpg)

10TH sheep feed pellet line in Saudi. Fusmar is a professional feed pellet production line manufacturer with about 15 years experience, we have our own R&D engineer and after sales service team. If you are interested in the animal feed production line, please contact us.

.jpg)

The small poultry feed production line includes of grinding, mixing, conveying, pelletizing and cooling sections. The diameter of final feed pellets can be optional by 2-8mm. It is a multifunctional feed pellet making machine which is suitable for processing feed pellets for various kinds of poultry, livestock, pet and fish.

Send Enquiry Now. Flat die pellet mill belongs to small pellet mill because of its capacity (under 800kg/h), it is applicable for makingfish, sawdust, straw, rice husk, bark, weeds, alfalfa, etc. into high density biomass pellets. The pellets are mainly used as fuel for home heating, central heating boiler, animal bedding, or as feed for poultry.

Small Scale Animal Feed Pellet Production Line. This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the

Aug 25, 2018 · Diesel Feed Flat Die Pellet Mill is designed for small-scale production, particularly for homeowners and small-scale producers to make pellets for animal feed pellets. The model has outstanding advantages of simple structure, low consumption and competitive price. Driven by a diesel engine, the diesel flat die pellet mill can run smoothly and

Jul 21, 2020 · Troubleshooting of Diesel Flat Die Feed Pellet Machine. 1. Low feed pellets production. ♦The first time a diesel flat die feed pelletizer is used with feed pellet produce. The production will increase after using several times. ♦Material moisture content is too high or too low. Adjust the material moisture content.

Jun 10, 2017 · Our 10t/h feed pellet production line has been installed in Saudi Arabia.The customers are very satisfied for our machines and service. The detailed process of 10t/h poultry feed pellet production line: Step 1. Raw materials receiving and cleaning process (drum sieving pre-cleaner, conical powder sieve and permanent magnetic drum).