.jpg)

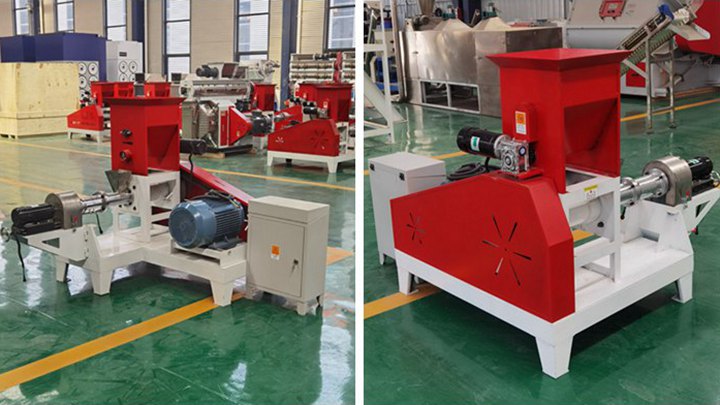

Small Scale Feed Pellet Production Line/Mini Feed Pellet Plant, Find Details about Flat Die Feed Pellet Plant, Small Scale Pellet Feed Plant from Small Scale Feed Pellet Production Line/Mini Feed Pellet Plant - ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.

Flat Die Feed Pellet Mill. Dewatering Screw Press Machine. Fish Feed Extruder. Small Capacity Feed Pellet Production Line For Making Animal Feed / Fish Feed.

It can be used both sides, so the production cost is saved for users, since the flat die is a main wearing part in flat die poultry feed pellet mill. The symmetry of flat die determines it can be used both sides. 3.Roller characteristic. The features of flat die pellet machine roller are that it has low rotating speed and large diameter.

Pellet Mill For Small Feed Production Line 200-600KG/H Flat Die Pellet Mill Get Quotation! Small flat die pellet machineis used by many small scale animal feed mill plant or farms to make animal feed, since it has relatively small capacity and does not occupy too much funds or area. 9KLHD Ring Die Pellet Mill(0.5-3.5T/H) Get Quotation!

Wood chip biomass straw 2 3 rollers feed processing pellet mini pellet flat die small scalefish pellet machine pelletilizer $185.00-$380.00 / Piece 1 Piece (Min. Order)

1 t/h pellet feed production line In order to meet the needs of the majority of small and medium-sized farmers and feed producers, we have designed and developed a flat-die pellet feed production line with a capacity of 1 ton per hour, can. Whatsapp: 0086-13419860671. Wechat: 0086-13419860671. Tel: 0086-13419860671. Email: info@cnhengfu.cn.

.jpg)

Flat Die Feed Pellet Mill Features and Application: 1. Driven by electric motor is more energy-saving and environmentally friendly. 2. Both the rollers and the flat die have passed wear-resistant process. The two sides of the flat die are exchangeable, which extends its service life and lowers cost. 3.

There are two types of small poultry feed pellet mill offered: electric feed pellet mill and diesel feed pellet mill. 1.Features and Advantages. (1) Simple structure and wide applicability. Cover small area and have low noise. (2) Roller and flat die are made from precise material of alloy steel, wear-resistant and not easy to break.

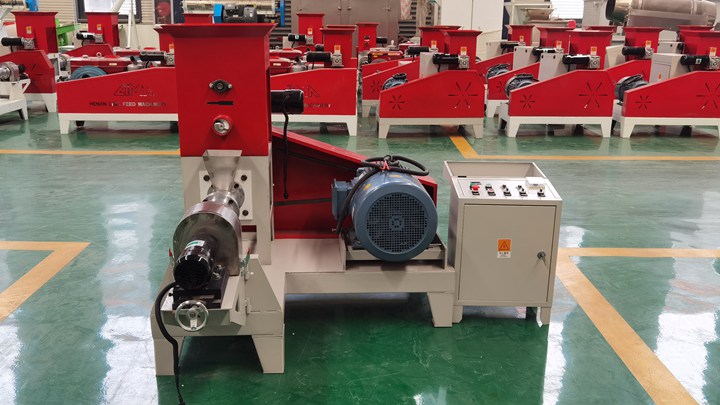

Feed Pelletizer. The feed pelletizer in this small feed pellets production line has two types: ZLSP300B and ZLSP400B. The feed pellet mill machine presses feed mesh (like oil seeds meal, bone powders and corns, etc) to form pellets with uniform size (the same diameter and length). The feed pelletizer is a kind of flat die pellet mill and a good

.jpg)

Flat die pellet mill belongs to small pellet mill because of its capacity (under 800kg/h), it is applicable for makingfish, sawdust, straw, rice husk, bark, weeds, alfalfa, etc. into high density biomass pellets. The pellets are mainly used as fuel for home heating, central heating boiler, animal bedding, or as feed for poultry.

Main Equipments comprise SG40 Small Hammer Mill and SKJ250 Flat Die Pellet Mill. The capacity for this feed pellet line could reach 100-300kg/h. The working principle of small feed pellet line is easy. The materials for feed just need to grind by hammer mill and then the powders would be transported by conveyor. After pressing by pellet mill

Rollers in our flat die pellet mills are made from precise material of alloy metal, which makes this core part wear-resistant and not easy to break. In addition, flat die pellet mill usually have two or three rollers that enlarge the capacity of making pellets. Die Parts. The diameter of die holes in portable pellet mill is usually 1.5-12mm.

Small flat die pellet feed line Key words: Hammer mill Vertical mixer Screw conveyor Pellet machine Features: Cheap price, simple structure, wide applicability, small space-occupancy, high efficiency. For use: This unit is the first choice for medium and small feed processing plants, breeding plants, etc.

.jpg)

Why Choose Portable Pellet Mill to Make Your Own Pellets. Portable Pellet Mill is suitable for small scale industrial production and home use offish pellets making, animal bedding pellet making and animal feed pellets production.

.jpg)

The complete small mobile feed pellet production line includes crushing, mixing, granulating, cooling, screening and packaging and conveying equipment. The process flow is complete and reasonable, and the adaptability is strong, which can meet the needs of different users. This product is suitable for processing feed into high-density granules.