.jpg)

Oct 13, 2020 · The 500 kg/h poultry feed pellet production line is a complete set of machines that are specifically used to make feed pellets. if you plan to make feed pellets at home by your own, you may choose this set of machine.This poultry feed production line is generally including the following process: raw materials crushing process and feed mixing process, feed pellet making process, sifting process.

.jpg)

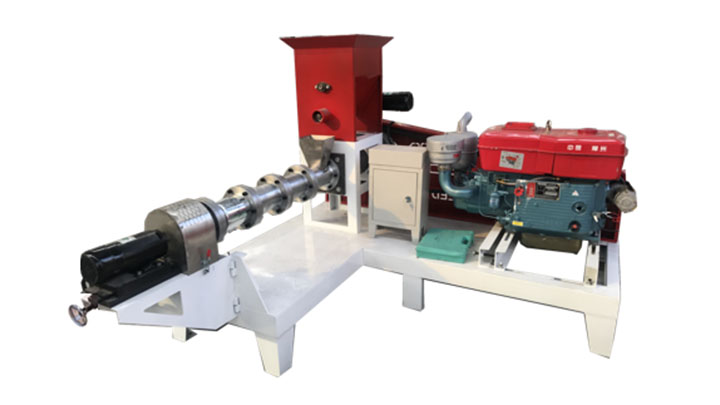

Aug 25, 2018 · Diesel Feed Flat Die Pellet Mill is designed for small-scale production, particularly for homeowners and small-scale producers to make pellets for animal feed pellets. The model has outstanding advantages of simple structure, low consumption and competitive price. Driven by a diesel engine, the diesel flat die pellet mill can run smoothly and

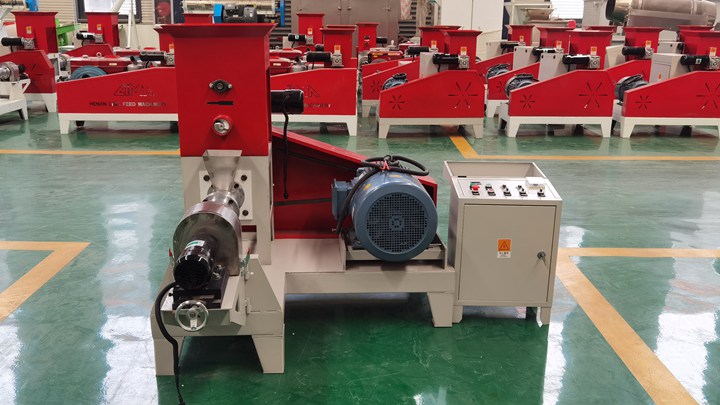

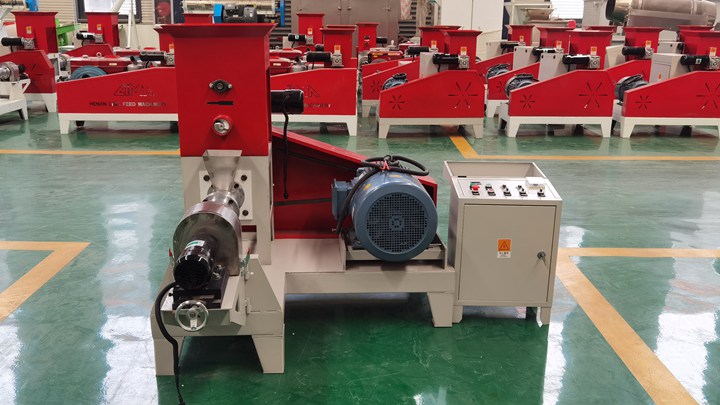

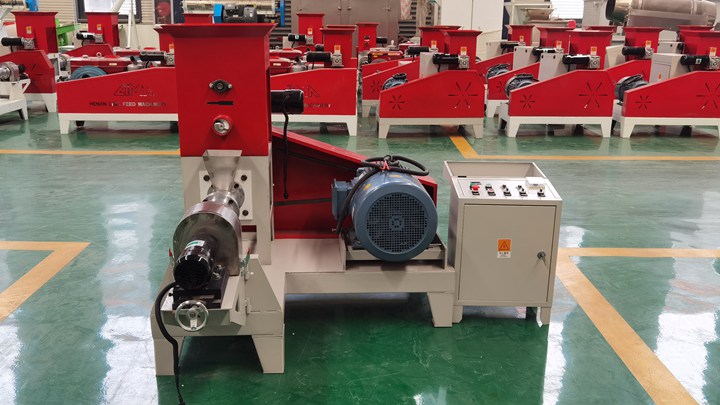

Henan Lima Machinery Manufacture CO.,LTD is a professional company in designing and researching, manufacturing, sales and service on Animal Feed Pellet Machinery. We have a worldwide business of various fish feed pellet extruder, as well as poultry feed pellet mill machine that can be also used for producing pellet feed for many other animals.

.jpg)

Small Pellet Line 200-800kg/h. Small pellet production line is a combination of biomass crushing, conveying, drying, pelletizing and cooling parts. All the equipments may include hammer mill/crusher, conveyor, dryer, small pellet mill, pellet cooler, etc. Not all of them are necessary; customer can choose according to your specific needs.

Weight: 940kg Motor: 18.5KW Voltage: 220V/380V Cutting power: 0.75kw Capacity: 300-350kg/h Type: Feed Pellet Machine Dimension(L*W*H): 2460*1550*1740MM

Advantages of Diesel Engine Feed Pellet Mill. 1. Driven by diesel engine. 2. Rollers and the die are made from precise material of alloy metal, which makes this core part wear-resistant and not easy to break. 3. Easy to get materials: corn, wheat, soybean, grass, alfalfa, straw, rice hull and so on. 4.

.jpg)

Diesel-type floating fish feed pellet machine Indonesia for cheapDiesel-type fish feed making pelletizer Indonesia for sale. floating fish feed, floating fish feed Suppliers and H E-MAIL:lima37@limamachinery.com

.jpg)

Make your own pellets from just about any material. Our systems allow the operator to make premium quality pellets for a vast array of materials for numerous purposes which includes but not limited to: Recent Videos. Hardwood Pellet Mill 22kw (30 HP) European design and manufacture. Wool pellets, high volume. Straw pellets web.

1.VICTOR brand feed pellet machine, the production process in the machinery itself under pressure to make feed pellet, it’s suitable for feed pig, cattle, sheep, rodents gnawing, improved feed portability, increase the intake of the animals. 2.Diesel pellet mill to facilitate feeding, high utilization, easy to control the feeding amount

.jpg)

Choose the right pellet mill for you. Learn more about our brand-new innovative Pellet Mill, now available in 4 sizes. Make pellets out of a wide range of materials using our industrial-grade pellet making systems.

Aug 25, 2018 · The feed pellet production line can be used to make various poultry feed and aquatic feed for rabbits, ducks, cattle, chickens, sheep, pigs, pigeons, fishes and shrimp etc. The whole production line can be control by the automatic PLC control system. The feed grinder can grind the raw material ingredients to the required size.

Specifications of completefish pellet line. Output: 60-1100kg/h; Power: single phase 2.2Kw, three phase 3-30Kw; Die aperture: 2.5-100mm

.jpg)

Search for used small feed pellet production line. Find Eternalwin and Luodate for sale on Machinio.

.jpg)

The small poultry feed production line includes of grinding, mixing, conveying, pelletizing and cooling sections. The diameter of final feed pellets can be optional by 2-8mm. It is a multifunctional feed pellet making machine which is suitable for processing feed pellets for various kinds of poultry, livestock, pet and fish.

.jpg)

Jul 21, 2020 · Troubleshooting of Diesel Flat Die Feed Pellet Machine. 1. Low feed pellets production. ♦The first time a diesel flat die feed pelletizer is used with feed pellet produce. The production will increase after using several times. ♦Material moisture content is too high or too low. Adjust the material moisture content.