Technical Parameters of main equipments for 1-2t/h poultry feed pellet production line: No. Product: type: Power(KW) 1.Raw materials receiving and crushing and mixing system

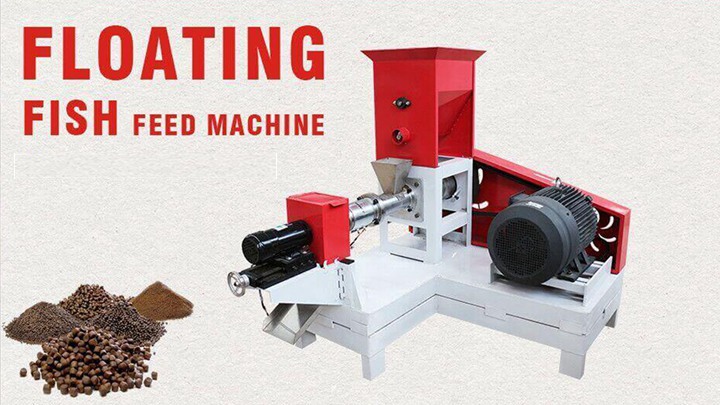

This is feed pellet line is widely used to make various poultry feed and aquatic feed for rabbits,ducks,cattle,chickens,sheep,pigs,pigeons,fishes and shrimp etc.The whole pellet line can be control by the automat

.jpg)

Poultry feed pellet mill is an ideal pelletizing machine for high quality feed pellets. Before pelletizing, grains such as corn, wheat, rice and soybean etc. need to be crushed into powder.

.jpg)

Jul 10, 2020 · For example, the 1-2t/h and 3-5t/h feed pellet machine asked by the customer this time, it is obvious that the tonnage is more than 1 ton, then you can choose the ring die pellet machine. Due to the large tonnage and high production requirements, the ring die pellet machine is more expensive than the general small flat die pellet machine.

Advantages of small feed pellet production line Excellent manufacturing: All machines have been strictly developed and manufactured to ensure high quality.Easy installation and operation: 1-1.2T/H Cattle Feed Production Line takes only a few minutes to assemble and install all the parts.

Electric control cabinet -Control each equipment of the production line. Counter-Flow Feed Pellet Cooler 3-5T/H,0.75KWCooler bring down the pellets at normal temperature (+4° max). Animal Feed Pellet Machine 1-2T/H,22KWGood pellet mill can ensure that produce good pellets. Vibrating Screen Classifier 3-6T/H,1.5KWScreen for impurities and grades.

This premix feed plant project was signed on May 28, 2020. The customer is from Thailand. The total area of the 10t/h poultry premix feed factory building of this advanced poultry premix feed mill 10tph project is 600m2, and the total construction area is about 1000m2.

.jpg)

Feed Pellet Machine; Feed Pellet Line; Tel: +86-519-86083312 Phone: +8613733816811 Email:info@bestpelletmachinery.com manager@bestpelletmachinery.com Add: No.69 Hongchang Road, Kunlun Street, Liyang City, Jiangsu Province, China

.jpg)

Richi Machinery The 1-2T/H feed pellet production line costs about 10,000-50,000 US dollars. The most critical factor affecting the price of the feed production line is the model (capacity) of the feed pellet machine and the configuration of the pellet machine.

.jpg)

Workshop size(L*W*H):10m*4m*5m. Main Raw material:Corn, wheat, and other Grain. The operate worker in this line: 2 person. Problem in the during installation: Our after-sales technical team very positive to guidance them how to install , and help them to solve these problem smoothly.

High quality 1-2T/H Feed Production Line , Chicken Feed Pellet Line Easy Operation from China, China's leading feed production plant product, with strict quality control pellet production plant factories, producing high quality pellet production plant products.

.jpg)

1-2T/H----Poultry Feed Pellet Production Line. This Line design for a lower invest and small capacity 1-2tons per hour animal feed pellet production line. Main Equipments: Single shaft mixer, screw conveyor, SZLH animal feed pellet machine, Cooling machine, bucket elevator, and package system. Installation : no need installation, just connect

.jpg)

Thailand Hot Sale Small Model 1-2t/h Animal Poultry Livestock Feed Pellet Production Line Farm Use , Find Complete Details about Thailand Hot Sale Small Model 1-2t/h Animal Poultry Livestock Feed Pellet Production Line Farm Use,Feed Pellet Production Line,Pig Feed Mill Plant,Animal Chicken Feed Pellet Machine from Feed Processing Machines Supplier or Manufacturer-Shandong Double Crane

.jpg)

1-2t/H Poultry Feed Animal Feed Pellet Production Line. Product model: customized per customer's capacity. Application: all kinds of animals such as chicken, cattle, sheep, pig, fish, shrimp feed processing industrial. Capacity: customized per customer's requirements. Final pellet feed size: 1.5-12mm (most popular animal feed size).

.jpg)

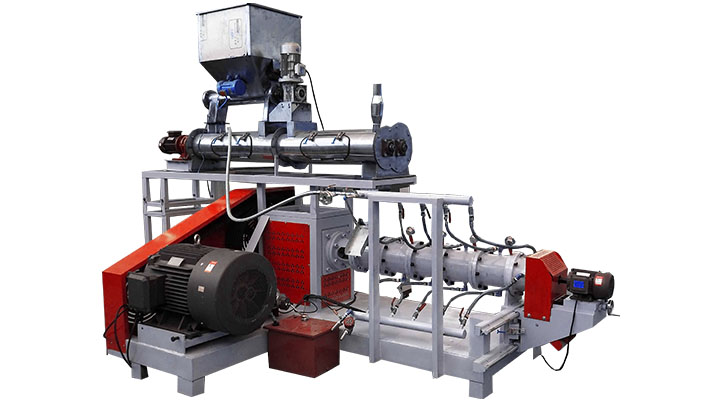

The main equipment of a complete 1-2 ton per hour feed pellet plant production line includes 37kw hammer mill crusher, 22kw szlh250 1-2 t/h feed pellet mill, single roller double rotary belt mixer, counter-flow feed pellet cooler, crumbler machine, pulse dust collector, vibrating screen, bagging machine, etc.