.jpg)

The feed pellet making machine is one of the key machines in the feed production line. It’s die mold is made of stainless steel or alloy steel for your choice. The feed pellet making machine has the characteristics of low cost, reasonable structure, compact layout, reliable performance and easy maintenance. 1.Features And Advantages.

The capacity of ring die pellet mill can be 500~2000kg/h. Small Ring Die Pellet Machine. Large Ring Die Pellet Machine. Output of Small Ring Die Pellet Machine: 500-800kg/h. Output of Large Ring Die Pellet Machine: 1.2-2.5ton/h. To get detailed machine parameters, price list, spare parts and more, please feel free to contact us directly.

Sep 10, 2016 · This Ring Diefish Pellet Machine capacity ranges are from 500kg to 1500kg per hour. According to the characteristics of biomass fuel pelletizing, it is mainly designed for pressing combustible materials such as saw dust and grass into pellets.

.jpg)

The reason is that the main part of this small ring die pellet mill machine is a circular ring, which is called a “die”. and there are 2 rollers inside the ring to rotate and extrude the biomass in the middle to go through the die holes and cylindrical pellets are made.fish Ring Die Pellet Mill Features. 1. Main drive adopts high accurate

.jpg)

Oct 16, 2018 · Introduction to Ring Die Poultry Feed Pellet Mill. Different from flat die feed pellet mill mainly used for making pellets for their own animals, ring die poultry feed pelletizer is more efficient and suitable for industrial poultry feed pellets production-large farms or feed pellets factory. Equipped with conditioner, this pellet mill

.jpg)

MSW pellets. Pellet Mills available in 4 Sizes.. 7.5kw (10 hp) 15kw (20 hp) 22kw (30hp) 33kw (40 hp) We offer systems that handle everything from grinding to packaging. Our turnkey pellet mills are suitable for 100kg up to 800kg per hour (depending on model and material). For our larger mills we have 75kw (100hp) or 220kw (300hp) Please contact

.jpg)

Sep 24, 2021 · Ring die feed pellet mill is one kind of animal feed pellet machine, which directly presses the granule of corn, soybean meal, straw, straw and rice husk. It is the main feed processing machine for animal food pellet, and its performance determines the feed processing output to a great extent and plays a very important role in feed pellet plant.

Small ring die pellet machine is designed to meet the demands of small pellet making business or to setup small pellet plant. It can process a various biomass materials into fuel pellets, including hardwood, straw,fish chips, sawdust, etc. More importantly, it overcomes the shortcoming of poor pelletizing effects of crude fiber.

.jpg)

Features. Ring die pellet machine is the essential equipment for large pellet production line. The capacity of GEMCO ring die pellet machine can reach up to 2000kg/h. Referring to ring die type pellet machine, the pellet roller and ring die both operate on the vertical axis. The inner and outer edges of the pellet roller cover the same distance

Characteristics of Vertical Ring Diefish Pellet Mill. 1.Feeding vertically, raw materials with no arching, easy for heating dissipation. 2.Key parts adopts superior alloy steel with heat treatment by German vacuum furnace, which together prolongs its service life by 5-7 times. 3.High precision gears with automatic lubricant pump system makes

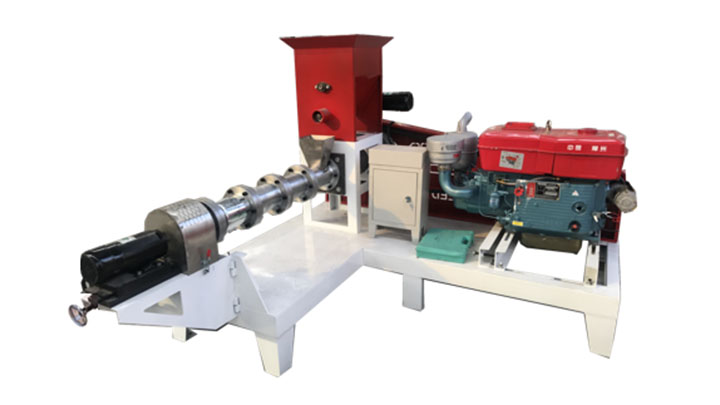

Flat Die Feed Pellet Mill - Small Scale. Flat die feed pellet mill is small scale feed pellet machine that is designed for small scale feed pellet production. Various power sources are available: electric motor, diesel engine, PTO, gasoline engine, you can choose according to your own needs. The feed pellet by flat die feed pellet machine can be adjusted into different size through different models of die diameters.

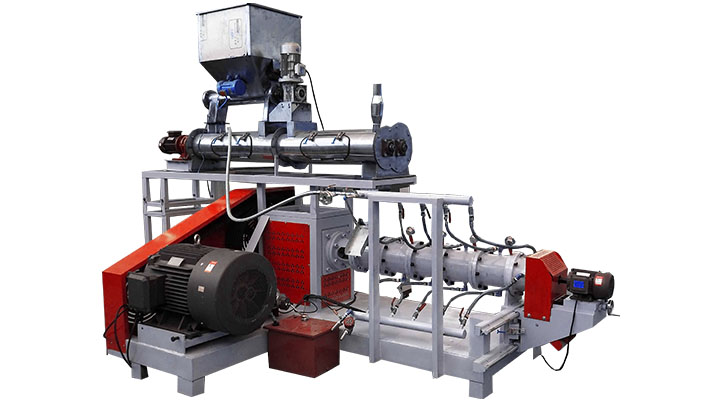

Mar 07, 2019 · Ring Die Animal Feed Pellet Mill. As the name suggests, the ring die feed pellet mill has a wide cylindrical shape die and is mounted vertically. It mainly consists of feeding device, hardening and tempering device, conditioner device, press chamber transmission system, overload protection and electric control system.

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

.jpg)

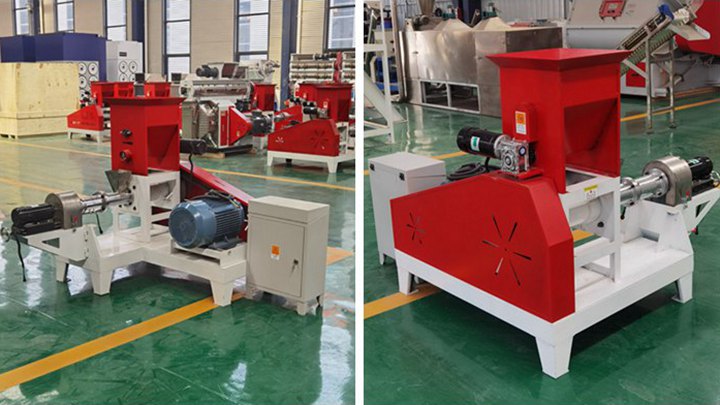

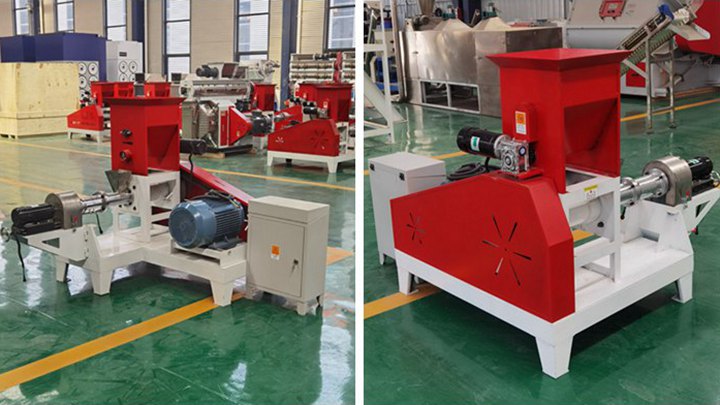

Aug 25, 2018 · Ring Die Animal Feed Pellet Mill adopts mature technology to make high quality animal feed pellets for chicken, cattle,horse,duck etc with large-scale production. Based on the outstanding features of its high throughput, low consumption and mature technology, ring die feed pellet mill has become more and more popular and possess broad market

.jpg)

Aquatic feed ring die pellet mill is an ideal pelletizing machine for large-scale high quality aquatic feed pellets. Grains such as corn, wheat bran, rice husks, beans, etc all can be the raw materials. The finished feed pellets have a smooth surface and easy to digest for fish and shrimps. Based on advanced technology and outstanding