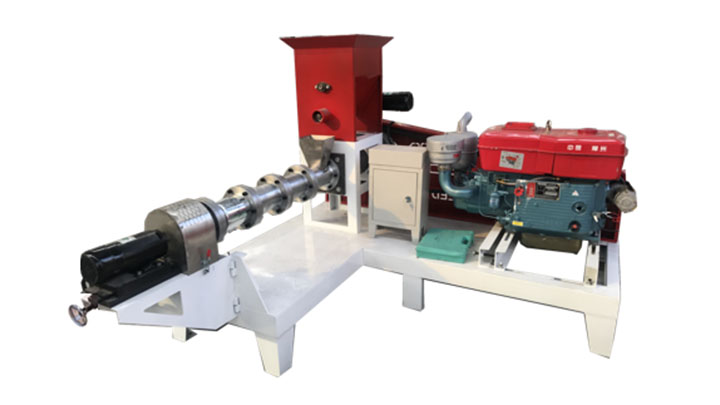

Flat die feed pellet mill is small scale feed pellet machine that is designed for small scale feed pellet production. Various power sources are available: electric motor, diesel engine, PTO, gasoline engine, you can choose according to your own needs. The feed pellet by flat die feed pellet machine can be adjusted into different size through different models of die diameters.

.jpg)

SZLH Series Ring Die Pellet Mill 9KLHC Series Ring Die Pellet Mill 9KLH Series Ring Die Pellet Mill 500-1000KG/H Feed Pellet Production Line. Flat Die Pellet Machine. 90-400KG/H smallfish pellet machine 200-400KG/H small animal feed pellet machine 300-500KG/H small animal feed pellet machine 400-600KG/H small animal feed pellet machine.

.jpg)

The animal feed pellet market is growing fast with recent years, the flat die feed pellet machines are welcome in the breeding industry. The flat die feed pellet machine has the advantages of simple structure, covering a small areas, low cost, and low consumption.

.jpg)

1.This kind of small pellet mill can do feed pellets, also can make softfish pellets, organic fertilizer pellets. Widely used for home, small or medium farm and business. 2.The spare parts of flat pellet machine use ear-resistant alloy steel material after treatment, which increase abrasive resistance. 3. Siemens Motor of pellet maker: more coil than other brand; Delixi electric components; This can make sure that the flat die pellet machine run steadily

.jpg)

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone.

Factory direct sales Poultry, pig, beef, chicken, duck, goose, animal feed, pellet machine extruder Flat Die Granule Mill. AUD $442.17 / Piece; Add to Cart Chat; Pastry Machines | Tender Machine. Report Item

You can use the flat die extrusion machine in all scales of aquaculture farms, food and feed processing plants, livestock farms, poultry farms and individual farmers. You can use it independently to deal with small quantities of materials, or you can put it together with other Shunxin fertilizer making machines.

The roller and main shaft bearings of small feed pellet machine adopt whole sealing design to ensure no leakage pollution from bearing and lubricating oil. The bearing service life is longer and saves the maintaining time. The flat die of feed pellet machine is made by alloy steel and with forging process.

.jpg)

There are two types of small poultry feed pellet mill offered: electric feed pellet mill and diesel feed pellet mill. 1.Features and Advantages. (1) Simple structure and wide applicability. Cover small area and have low noise. (2) Roller and flat die are made from precise material of alloy steel, wear-resistant and not easy to break.

Advantages. 1. Animal feed pellet machine is suitable for small-scale farm or home use with advantages of high capacity and low investment. 2. Raw material of poultry feed pellet machine are various, such as crushed corn, soybean, sorghum, wheat, little grass powder etc. 3. Power of feed pellet machine can be electric or diesel engine optional. 4.

.jpg)

Sep 01, 2016 · Features of Electric Flat Die Feed Pellet Mill. 1.Advanced technology employed, high quality and reasonable structure. 2.Driven by electric motor, which makes it more energy saving. 3.Low energy consumption, low noise and low failure rate. 4.Strong fatigue resistance makes continuous production possible, economic and durable.

.jpg)

Feed pellet machine is widely used in large, medium and small aquaculture framing, feed processing plants, livestock farms, poultry farms, small and larger individual farmers, also it is popular in large, medium and small feed processing plants.

.jpg)

The SKJ series small pellet mill is one of our mainly products, it is also be called at flat die pellet mill, and the small machine operate easily, and suitablefor home use.It can be used for making fuel pellet, fertilizer pellet, and animal feed pellet.The output volume is high, energy consumption is low and the operation is convenient. For pellet making, the size of input materials should

Difference between R and D type flat die pellet machine. Generally speaking, there are two types of flat die pellet machine, D type and R type. For electric motor and diesel engine flat die pellet machine can be divided into these two types, but for gasoline and PTO flat die pellet machine, they usually adopt D type, rather than R type.

Make your own pellets from just about any material. Our systems allow the operator to make premium quality pellets for a vast array of materials for numerous purposes which includes but not limited to: Recent Videos. Hardwood Pellet Mill 22kw (30 HP) European design and manufacture. Wool pellets, high volume. Straw pellets web.