.jpg)

Therefore, controlling the cost of the entire production process is particularly important for the development of a newly established poultry feed factory.The following are the poultry feed factory designs ofLima Machinery with different output, aiming to provide you with some ideas for plant construction.

It can be adapted to different feed formula. Livestock & Poultry Feed Milling Machine Details. For the ones who are planning to start their own poultry feed milling business, this project is a good reference. (Smaller Project: 30,000 tons per year Poultry Feed Mill Plant)

Oct 21, 2019 · Poultry feed production is generally divided into the following steps: receiving and cleaning of feed ingredients, crushing of raw materials, batching, mixing, pelletizing and packaging of finished feed. Raw material cleaning: It is a good production practice to clean poultry feed before starting processing. This cleaning machine can be used to clean the premix at the inlet.

.jpg)

May 31, 2013 · In case of automatic feeder the feed is supplied to the entire length of the poultry house by specially designed feed troughs with auger type or chain type devices to move the feed from the feed bins to the other end. These are operated with electricity and the height of the feeder can be adjusted depending upon the age of the birds.

Why use Poultry Feed Mill - Buy High Quaity Poultry Feed Mills to Make Poultry Feed Pellets: HOT Sale poultry feed mills offered by poultry feed milling machine manufactuer or supplier, Guide on process of poultry feed pellet production and How to start poultry feed manufacturing business with limited cost in Tanzania, Egypt, Morocco, Ghana,South Korea, etc.

.jpg)

Poultry Feed Making Machine, 300KG/HR,600KG/HR. ₹ 20,000. Khare Agro Mech Industries Private Limited. Contact Supplier. Pig Feed Pellet Machine, 100 kg per hr. ₹ 75,000. Zigma Machinery & Equipment Solutions. Contact Supplier. Poultry Feed Crumble Machine.

Ordinarily, sole proprietorship should have been the ideal business structure for a small – scale poultry feed mill especially if you are just starting out with a moderate startup capital in a small neighborhood. But people prefer limited liability Company for obvious reasons. 8. Choose a Catchy Business Name.

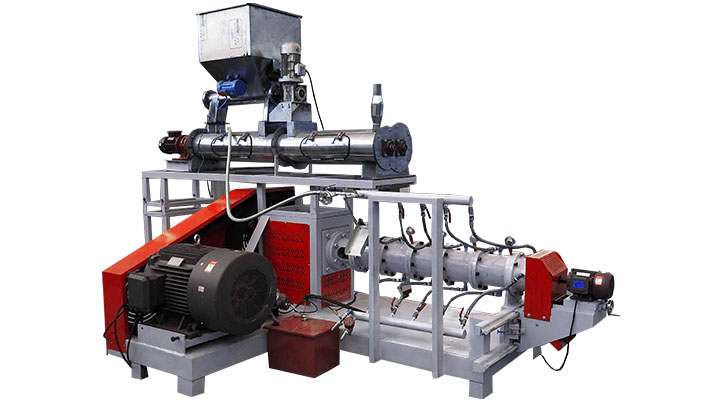

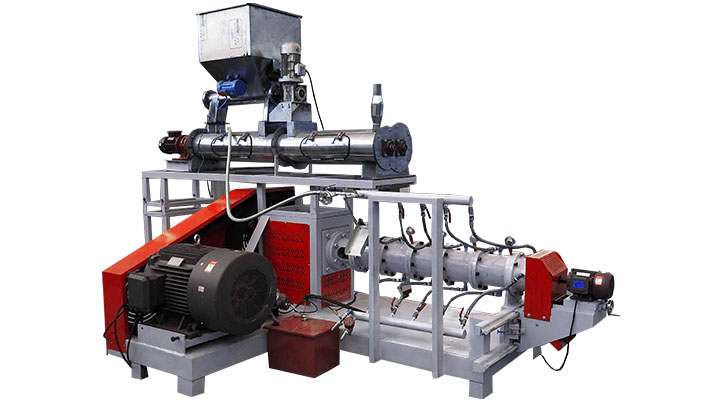

Compared with the same model in the chicken feed making machine industry, the small chicken/poultry feed pellet mill manufactured byLima Machinery has high output, low energy consumption, and the production reached 15-20 kg/kw, while other manufacturers generally reach to 10 kg/kw, unit production energy consumption is generally in 0.05-0.06 degrees / kg.

.jpg)

Liter of the house should be at least 3 inch depth.fish powder, sand or tush can be used as liter. Mix half kg of lime powder with the liter. Change the litter of the house after every one week. Never let the poultry house wet. You can raise poultry in open area (free range poultry farming system).

.jpg)

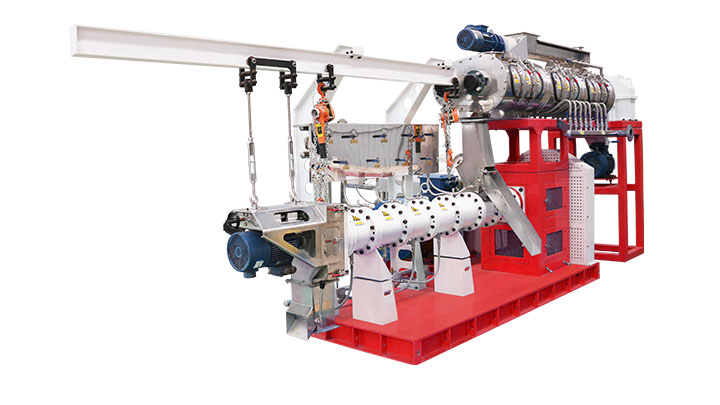

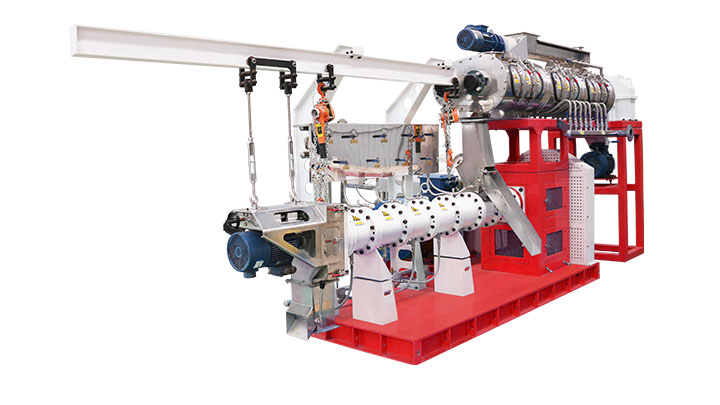

RICHI can customized poultry feed plant according to your requierment, The biggest capacity is 100t/h, can production the 2-12mm duck feed pellet. We also provide the free design , such as the equipment layout , flow chart, pit plan, Installation plan, land plan and 3D drawings. Capacity: 1-100T/H.

.jpg)

poultry feeding equipement. chain. Reliance Poultry Equipment 1.) Better management because of individual feed distribution from one line one way – six line two way 2.) Speed of 18 – 32 m per minute 3.) Enough space for the comb stepped pan + 10 individual

Production Output Range: 1~1000,000 tons/year.Lima Machinery supplied poultry and cattle feed plant adopts module design which can realize customized feed processing plant. Meanwhile, as an experienced feed mill machine factory, we can also help you make the best business plan for setting up your own animal feed pellet plant, like mini poultry

These are equipment the farmer uses to purify water used for poultry activities. 1. Water softeners and filters: Water softeners and filter systems are used to reduce the TDS content of the water used for hatchery operations. Both large-scale and small-scale farmers need this. 2.

.jpg)

Get Price Now! The process of making chicken pellets for your chicken is simple and it involves: Use a feed hammer mill to grind the ingredients so that they become fine powder ingredients/mashed potatoes. Next, mix all the ingredients in the feed mixer and wait until the mixture is even. The moist viscous mixture shall be the final mixture.

The most common raw material used for making poultry feed pellets is whole maize, maize bran, fish meal, soybean meal, cottonseed cake, brown rice, etc. Hammer mills are generally used as crushing machines. Feed Mixing Machine: A feed mixing machine is used to mix all the ingredients of poultry feed pellets. Mixing them is important to make