Usa Pellet Mill offer you a wide stock of pellet mills, hammer mills, extruders, presses and many others solutions for your farm. USA Pellet Mill +1 (786) 918 3634 | info@usapelletmill.com

.jpg)

For pig feed pellets making, the screen sieve diameter of feed hammer mill is less than 1mm, while for weaned piglet is only 0.3mm. Raw materials mixing. Mixing is an essential operation for the whole pig feed pellets production line.

.jpg)

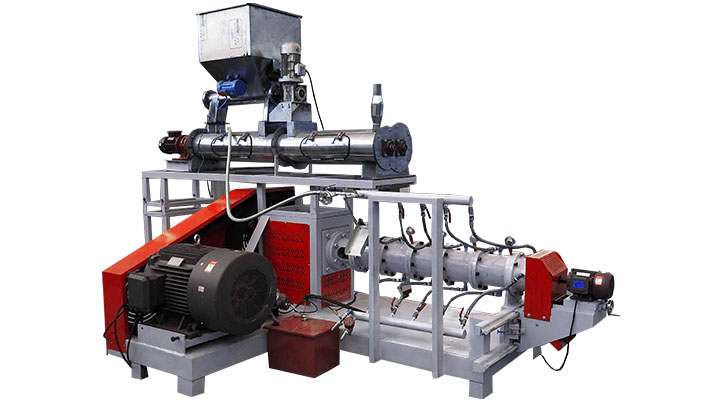

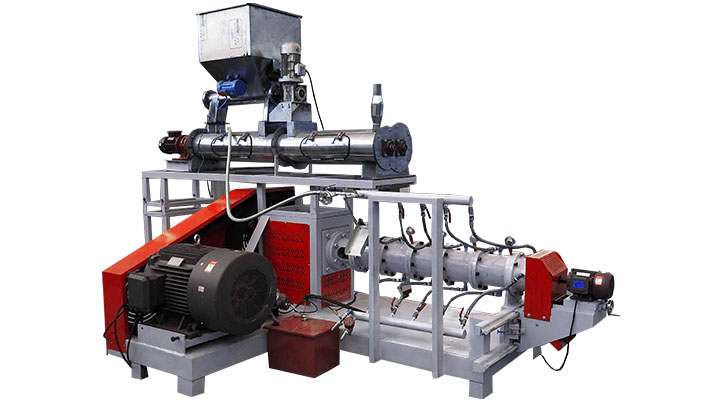

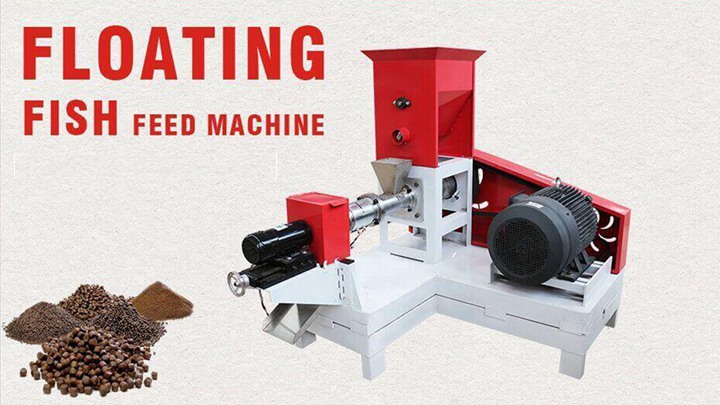

customized. 60-5000kg/h. 1 year. Make feed pellets for all kinds of fishes, suitable for fish pond holders and feed pellet manufacturers. 200-300kg/h Small Feed Pellet Line. Get Free Quote! 400-600kg/h Feed Pellet Production Line. Get Free Quote! 800-1000kg/h Feed Pellet Production Line.

.jpg)

Usually, suckling pigs: 2-3mm pellets, piglets: 3-3.5mm pellets, growing pigs: 4-6mm pellets, and sows 2-12mm pellets. The use of pig feed pellets in pig farms can greatly reduce pig feed waste, improve feed utilization, kill harmful parasites, and reduce the probability of pig disease.

.jpg)

Wholesale Feed pellet mill- UCOWIN provide machine and solution for your feed pellet making to sell - provide Cheap Hammer Mill from sugarcane-juicer.

Homemade Pellet Mill. PMF9E15 Biomassfish Pellet Machine. Details of Pellet Machine for Home: Die Parts: The die parts of this home pellet machine have many holes that are used for shapping the raw material into pellets. The diameter of the holes range from 6 to 8mm and you can shoose the right die depending on your needs.

Pelletizing Procedure of Pig Feed Pellets. Pelletizing is a core step for pig feed pellets producing. Because moisture conditioning and temperature control in the pelletizing process influence the pellets quality a lot. Commonly, the most suitable moisture content of the raw materials for feed pellets processing is 16% ~ 17% after conditioning.

.jpg)

Shandong Kingoro Machinery Co., Ltd [Shandong,China] Business Type:Manufacturer Main Markets: Africa , Americas , Asia , Caribbean , East Europe , Europe , Middle

.jpg)

Feed for Thought. Nutrition of the weaned pig is a process. Learn how phase feeding pigs can positively impact their growth and overall health. Sows require different nutrients in gestation and lactation. Learn the difference between pig gestation and lactation feeds. Weaning piglets can be challenging for pigs and swine producers alike.

China Feed Pellet Mills SZLH400(420)a2-#6010 is supplied by Feed Pellet Mills manufacturers, producers, suppliers on Global Sources,Feed Pellet Mills,Pig Feed Pellet Mills,feed pellet mill manufacturer

Actually, the feed production process is based on the pig feed plant design. A complete pig feed mill plant might feed crushing machine, feed mixing machine, feed pellet machine, feed pellets cooler and other kinds of auxiliary equipment . (Recent News: 3~5ton/h feed processing machine shipped to Africa) Within the process there are four main

.jpg)

Feeding Instructions. Feed Mini Pig feed to adult mini pigs at a rate to support the desired body condition. This will typically be in the range of 1.0 to 2.0% of body weight each day in two separate feedings. If the pigs ribs can be felt through a slight layer of fat using gentle hand pressure the pigs is in ideal condition.

For pig feed pellets making, the screen sieve diameter of feed hammer mill is less than 1mm, while for weaned piglet is only 0.3mm. Raw materials mixing. Mixing is an essential operation for the whole pig feed pellets production line. Grounded raw materials should mix evenly before sent to be pressed.

Pellet Mill - 30T/H Cattle Chicken Pig Fish Shrimp Aquatic Livestock Ruminant Animal Poultry Animal Feed Pellet Mill

However, pig feed pellets is made of pig feed raw materials, compressed by an pig feed pellet machine. Under the action of 100 ~ 120℃ hot steam during the pelletizing process, pig feed pellets will soon become gelatinized and generate a better taste. It is easier for pigs to digestion and absorption. Processed under high temperature, pellets