.jpg)

Feb 15, 2019 · Here’s a home remedy for lice control. Get a four- to five-foot pipe with a diameter of 1-1/2 to 2 inches. Drill small holes from one end to the center. Drive the pipe halfway into the ground and wire some burlap around it. Fill the pipe with old oil. The oil will seep into the burlap, and the pigs will rub against it.

Dec 27, 2021 · 125TPH large animal feed processing plant project construction site. Power supply system of the 125 tons per hour large animal feed processing plant for pig fish duck chicken feed making. The large animal feed processing plant project is expected to consume 50,000 kilowatt-hours of electricity per year for municipal power supply.

.jpg)

Therefore, a pig farmer should ensure the temperature in the pig house is below 35 o C. The following are the ideal temperatures for pigs (of different ages) for optimum feed conversion and growth. 1 day old piglets — 35°C. 1 day-1week old piglets — 30°C. 1-6 weeks old piglets — 24-30°C. Pigs from 20-60kg — 20-26°C.

.jpg)

Given that obvious depth of knowledge as well as personal experience in raising pigs, Irene then instructs in a step by logical step how begin by selecting types/breeds, a detailed explanation of the various types of pigs, how to maintain pigs (shelters, bedding, nutrition, possible ailments), breeding, butchering and more – all information

Apr 25, 2018 · Read More: “Pig Slaughter”. Now, we are moving on to hog processing. Here’s a quick overview of the basic steps that we’ll cover in this post: Step #1: Choose How You’ll Handle the Pig Hide. Option #1: Remove the Hide. Option #2: Remove the Hair. Step #2: Remove the Head. Step #3: Disconnect the Rectum.

Jan 23, 2018 · Cactus sells all its pigs, about 750,000 a year, to Tyson Foods. Cactus is 100% employee owned. All 850 employees are part of the ESOP (employee stock ownership plan). Prestage Farms is a family-owned hog and turkey production business based in Clinton, North Carolina. The company is building a pork processing plant near Eagle Grove, Iowa.

.jpg)

The cheapest way to feed pigs for butchering is to use ground feed from your local feed mill at $0.14/pound. If this is not an option for you, the next cheapest is to make your own feed at $0.22/pound. Check out the prices in your area, these are the current prices for us.

.jpg)

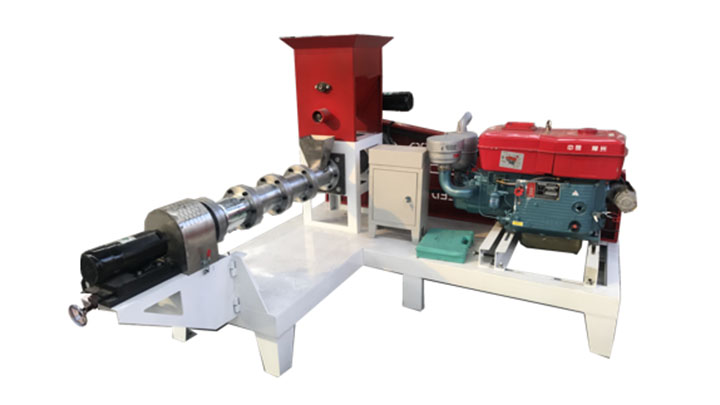

Characteristics of animal feed production line. Customizable design for the whole plant. For different materials, depending on your specific needs or budget, we can add or remove some machines. Wide capacity range. Its processing power ranges from 1t/h to 20t/h. If you have more production needs, we can also customize for you.

.jpg)

Kiran Engineering Company - Offering Semi-Automatic Pig Feed Plant, For Industrial in Gurdaspur, Punjab. Get best price and read about company. Get contact details and address | ID: 14104641891

Pork meat processing can give consumers more choices when buying. Pork processing can increase the company’s sales profit. Prepare for deep processing of pork. 5 stages of complete pork processing. Storage of pig carcass: Acceptance of pig carcass: Meat quality is an important factor that directly affects sales.

Jan 08, 2016 · Give lactating sows 2.5 kg a day of sow and weaner meal for maintenance and 0.25 kg a day extra for each piglet being suckled. Boars: Give boars 2.0 kg a day. If the boar is regularly used increase this to 2.5 kg. Piglets: Give creep pellets 0.5 - 1.0 kg a day from day 7 up to weaning time (21 days) per piglet.

.jpg)

You should give your pigs a selection of fresh fruits and vegetables. Fresh fruits and vegetables help to keep your pigs healthy, just like humans. Most of the fruits and vegetables are safe for the pigs that human consume. Leafy vegetables are good for the pigs such as cabbage, lettuce, sweet potato vine, spinach etc.

.jpg)

A complete pig feed mill plant might feed crushing machine, feed mixing machine, feed pellet machine, feed pellets cooler and other kinds of auxiliary equipment. (Recent News: 3~5ton/h feed processing machine shipped to Africa) Within the process there are four main steps: Raw Feed Stock Moisture Control; In this step, the aim is ensuring that the moisture of the raw materials used for making pig feed isn't higher than 10-12%.

Sep 17, 2018 · Expected Pig Growth Rates. Because a pig eats approximately 4% of its body weight per day, they require a number of essential nutrients to meet their daily needs, i.e., water, carbohydrates, fats, protein (amino acids), minerals, and vitamins. With a proper diet, expect weight gains of about 1.5 to 1.7 pounds per day up to approximately 110 pounds.

You can select the most economical ingredients for preparing the feeds. Basic ingredients of pig feed are oat, grains, maize, wheat, rice, sorghum and other millets. You can add some protein supplements like oil cakes, fishmeal and meat meal. Add all types of mineral supplements and vitamins.