.jpg)

How to use the feed pellet process machine to make pig feed Pig Feed Formula 1. Piglet stage (weight 10kg-20kg): corn 60%, wheat bran 10.5%, peanut cake or bean cake 15%, domestic fish meal 10%, yeast meal 3%, bone meal 1%, salt 0.5%. 2.

.jpg)

Pig Farming and Pig Feed Machines. In comparison to other livestock rearing, the advantages of pig farming are extremely high. The growth rate of the pig farming business is very high. Within a short span of time, one can increase the quantity of livestock as pigs are the most prolific breeders with high fertility and shorter generation interval.

.jpg)

Nov 19, 2019 · Pressing is the core process of pig feed pellets production. During this process, water, temperature and steam pressure have a great influence on the mass of the final pellets. If the moisture content of the raw material is higher than 8-10%, the hardness of the particles will increase. The optimum moisture content is 16-17%.

.jpg)

The Benefits of Pig Feed Pellets. 1. Less feed waste and less segregation of diet ingredients during feed handling. Feed pelletization helps to make it easier to process the feed and helps reduce feed waste. In addition, though making pig feed pellets can be costly, the benefits far outweigh the cost. 2.

Pig feed pellet machine Screw feeder. The structure is similar to the batcher. The motor is frequency-regulated or speed-regulated, and there is a steam baffle at the feed inlet. The function of this machine is to evenly send the materials from the granulator bin to the conditioner, and the feeding speed can be adjusted according to the load of the main motor of the pig feed pellet machine.

Working principle of animal feed pellet machine. when feed pelleting process,the powder raw materials go into the pelleting champer through the feeding hopper,under the press and friction between the rollers and flat die of the animal feed pellet machine,the raw materials are extruded from the die holes and formed pellets.the temperature can reach to about 65-70 degrees,which can completely

0.75kg of lime. 1kg of bonemeal. 125g of salt. 150g of lysine. 150g of feed premix. 300g of zinc. This pig feed ration has a Digestible Crude Protein (DCP) content of 22.3% and can be given to pigs at all stages of growth. Put all the ingredients in a feed mixer and mix thoroughly to ensure they are evenly distributed.

.jpg)

Shandong Kingoro Machinery Co., Ltd [Shandong,China] Business Type:Manufacturer Main Markets: Africa , Americas , Asia , Caribbean , East Europe , Europe , Middle

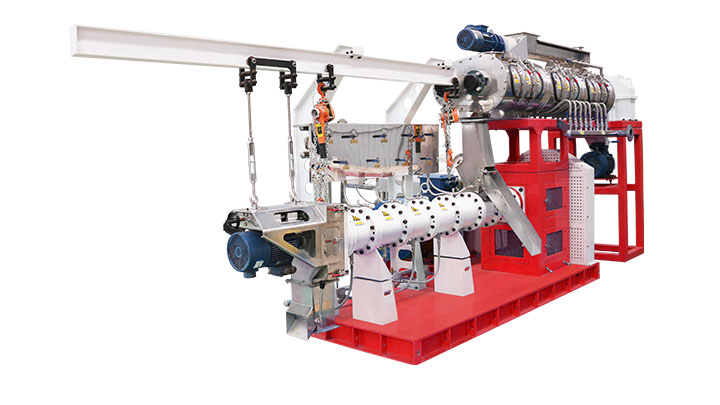

Pig feed making machine is divided into ring die granulator, flat die granulator, and roller granulator. According to the production can be divided into straw feed pellet machine, wheat bran feed pellet machine, soybean meal feed pellet machine, corn straw feed pellet machine,fish pellet machine, and so on. A variety of Pig feed machines are classified according to their appearance and production methods.

.jpg)

Pig feed pellets cooling and packing. Pig feed pellets are soft and hot after processed by feed hammer mill, so transfer them into the feed cooling machine to remove heat and moisture contained in the pellets becomes necessary. After cooling, pellets are dry and hard, they can be transported to the packing machine to be packed in bags, which then becomes convenient for storage and transportation.

Actually, the feed production process is based on the pig feed plant design. A complete pig feed mill plant might feed crushing machine, feed mixing machine, feed pellet machine, feed pellets cooler and other kinds of auxiliary equipment . (Recent News: 3~5ton/h feed processing machine shipped to Africa) Within the process there are four main

Generally, the length after pulverization by the crushing system of the feed crusher is 6 mm or less. The common animal feed crushing machine is the pig feed hammer mill grinder. (3)Mixing And Stirring Process. After the pulverization process of the pig feed pellet making plant, the material conveyed to the mixing and agitation process.

The pig feed pellet machine is designed with a flat die structure and is a good pig feed making machine for people who want to save the cost of making pig feed pellets. This pig feed machine is a popular product for homemade pellets. It has small size which makes it very easy to move and can be powered by diesel engine or electricity. The key components of the pig feed pellet making machine are a flat die and a pellet roll. During granulation, the prepared raw material falls into the area

Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs, rabbits, camels, deer, and other animals. This livestock feed pellet machine is widely used in small and medium feed factories, farms, and family units. commercial feed pellet mill for sale Why feed pellets to livestock?

This pig feed pellet mill machine model absorbs the essence of domestic and foreign pellet machines, and is a new energy-saving product. In the past, feed was generally processed into powder and then fed, which has the defects of inconvenient feeding, poor palatability, picky eaters of livestock, and low utilization rate.