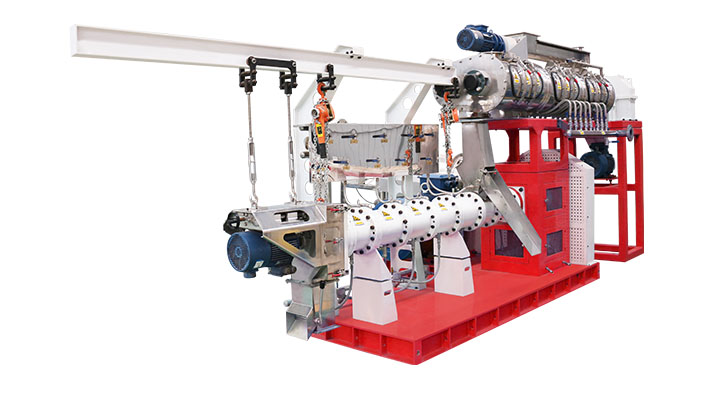

Introducing the Conical Double Screw Extruder - the ultimate solution for efficient and precise plastic extrusion. With its innovative design and advanced technology, this extruder offers superior performance and versatility.

The Extruder Double Screw industry is witnessing several trends. Increasing demand for plastic products, rising adoption of extrusion technology in food processing, and advancements in screw design for improved efficiency and flexibility are some key trends.

.jpg)

Top 10 Most Popular Chinese Double Screw Extruder Machine Brands January 14, 2024 The consumer market for Double Screw Extruder machines is witnessing significant growth due to their versatility and efficiency in various industries such as food processing, plastics, and pharmaceuticals.

Double-screw extruder (contra-rotatory) In the field of extrusion, as well as co-rotatory double-screw extruder gear units, FLENDER also offers contra-rotatory double-screw extruder gear units in vertical and horizontal versions. Thanks to consistent standardisation of the housings and interior component parts we can ensure short delivery times.

The Conical Screw Extruder industry is experiencing rapid growth due to its versatility in processing various materials like plastics, rubber, and food products. The demand for high-performance extruders with improved efficiency and reduced maintenance costs is pushing manufacturers to innovate and develop advanced technologies to stay competitive in the market.

Feb 27, 2024 · In the sphere of plastic manufacturing, extrusion plays a pivotal role. Single and twin-screw extruders, the primary types, offer unique advantages for shaping plastic materials.

This webinar defines the basic geometry for co-rotating, intermeshing twin-screw extruders and the influence of design criteria (e.g. torque density, diameter ratio) on operational performance. This is an excellent introduction for those who are new to twin-screws as well as a good refresher for seasoned professionals.

.jpg)

Aug 3, 2022 · A single screw extruder is an extruder with only one screw in the barrel. It is the most technically mature and most used type of extruder. Meanwhile, single screw extruders have become the leading equipment in compound processing and plastic blown film because of their small space occupation.

The popular common twin-screw extruders (in the family of multi-screw extruders) include tapered screws or parallel cylindrical screws with at least one feed port through a hopper, a discharge port to which a die is attached, and process controls such as temperature, pressure, screw rotation (rpm), melt output rate, etc. 143

Jan 1, 2020 · Single-screw extruders are usually supplied with premixed materials which often has been preconditioned with added moisture because they have relatively poor mixing ability (Guy, 2001). A typical single-screw extrusion system consists of a live bin, a single-screw barrel with a screw and die plate, and a cutter (Fig. 1, Fig. 4). 5.2.2.

.jpg)

Screw extruders are divided into single screw and multiscrew extruders. Single screw extruders are most popular for their low cost, simple designs, ruggedness, and reliability. Typical sizes vary from 1 to 6 inch (25 to 150 mm) and L/D ratio from 20 to 30 with 24 being most common. Basic operation of a single screw extruder is described in the

Dec 12, 2023 · The vast majority of double screw extruders are mainly composed of two intermeshing screws, and their structure is relatively more complicated; while the single screw extruder mainly

Mar 4, 2006 · HSEI twin-screw extruders process materials bounded by screw flights and barrel walls. Screws are segmented and assembled on high-torque splined/hammered shafts that allow the maximum torque to be applied to the process. Screw speeds are available to 1200+ rpm.

Sep 19, 2021 · Double-flighted and wave screws. Double-flighted screws have two parallel paths in part or all of the screw. In the metering zone, this helps heat transfer, so it is sometimes used where very high temperatures are needed, such as extrusion coating. A double-flighted feed zone is believed to give smoother feed (less pulsation) but is seldom seen

Screw Size – The Screw is the heart of the extruder. It is measured in outside diameter most extruders are between .75”-10”. The most popular sizes are 1.5”, 2.5”, 3.5” 4.5 and 6”. The effective length of the extruders typically 24-36 L/D although can be shorter or longer for specialized applications.