Twin-screw extruder (TSE), originally built and developed for plastic and rubber industries approximately 100 years ago, is now slowly but steadily gaining popularity in the pharmaceutical industry for manufacturing various dosage forms.

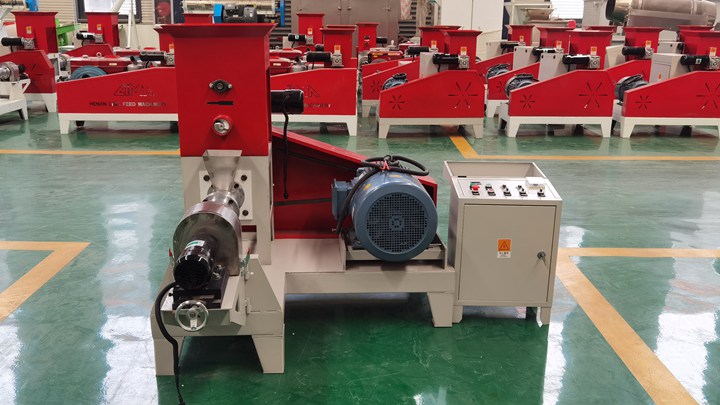

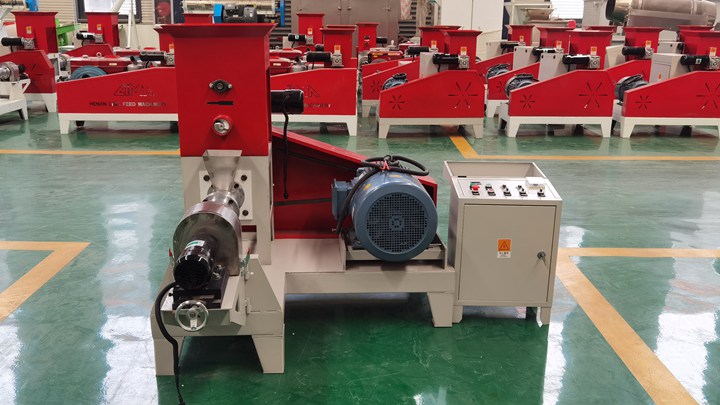

China Compound Twin Screw Extruder wholesale - Select 2024 high quality Compound Twin Screw Extruder products in best price from certified Chinese Plastic Extruder Machine manufacturers, Plastic Machine Screw suppliers, wholesalers and factory on LimaFeedPelletizer.com

GSmach supply turn-key solutions with our twin screw extrusion machine to your compounding projects, including material handling, dosing, extrusion, pelletizing and other aspects. 跳至内容 +86 15312989585

Twin Screw Extruder Heater – A Reliable and Efficient Solution for Your Manufacturing Needs . As a manufacturer located in China, we are proud to present our latest offering – the Twin Screw Extruder Heater. This state-of-the-art product is designed to take your manufacturing process to the next level with it

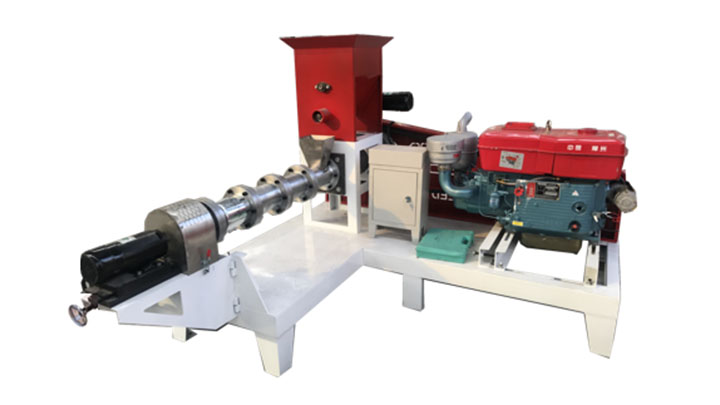

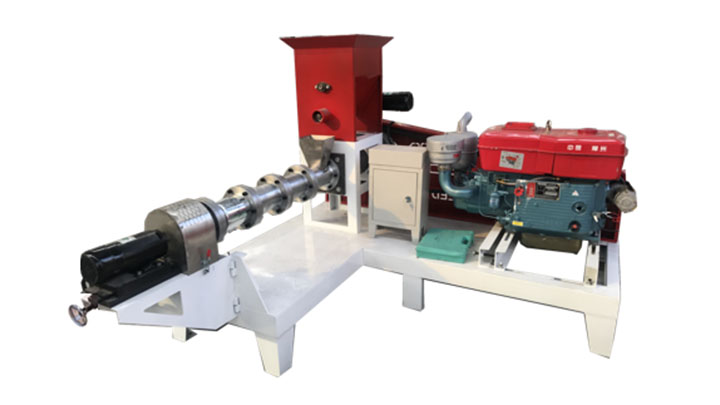

Sep 14, 2023 · What is Twin Screw Extruder Machine? A twin screw extruder machine is a specialized equipment designed to process and extrude various materials, particularly polymers and plastics. Unlike its single-screw counterpart, the twin screw extruder features two parallel screws that rotate in the same direction within a heated barrel.

.jpg)

Dec 1, 2023 · For example, twin-screw extruders are commonly used in the production of breakfast cereals, snack foods, pet foods, and confectionery products. The ability of twin-screw extruders to handle a wide range of raw materials and provide precise control over temperature and pressure makes them well-suited to the food industry’s needs.

Mar 3, 2006 · There are two distinct families of twin-screw extruders, defined as low-speed late fusion (LSLF) twin-screw extruders (run up to 50 rpm), and high-speed energy input (HSEI) twin-screw extruders (run up to 1200+ rpm).

.jpg)

Jan 1, 2017 · Continuous granulation via a twin-screw extruder can be used to replace the traditional granulator in a bin-to-bin manufacturing setup, or it can be integrated into a continuous manufacturing line as demonstrated in GEA’s ConsiGma system.

.jpg)

Apr 28, 2024 · Types of Screw Design (Single Screw, Twin Screw): A single-screw extruder may be used over a twin-screw one depending on its application needs; mixing capability is improved by the latter as well as the venting ability and handling complex property materials, while single screws are known for their simplicity in use coupled with cost-effectiveness.

The following is a brief technical review of currently available twin screw extrusion (TSE) technologies, and an overview of the features and process advantages inherent with this powerful and industrial-proven 24 hr/day manufacturing device. TSE technology: 2-screws interact with each other.

.jpg)

Application examples of the double screw extruder are as following: Reinforced glass fiber, fuel resistant granulation (such as nylon 6, nylon 66, polyester, polybutylene terephthalate, polypropylene, polycarbonate, etc.), high packing granulation (such as pe and pp with the filling of 75% caco3) and granulation of heat sensitive materials, such as pvc and cross-linked polyethylene cable

On the premise of the same output, the parallel twin-screw extruder is more energy-saving. For instance, Both PS130-28 (parallel twin-screw extruder) and SJSZ110-220 (conical twin-screw extruder) can produce 40 Tons of SPC floor per day, but the main engine power of PS130-28 is only 110KW, while that of SJSZ110-220 is 200KW.

We're professional Twin Screw Extruder factory, which is developed on the basis of single screw extruder, because of the good feeding, mixing and molding performance, exhaust performance, extrusion stability and other characteristics, it has been widely used in the molding and processing of extrusion products.

.jpg)

Laboratory Twin Screw Extruder/20mm Lab Scale Twin Screw Extruder/20mm Lab Extruder /Small Twin Screw Extruder FOB Price: US $16,000-40,000 / Set Min. Order: 1 Set

Dec 1, 2023 · A: A single-screw PVC extruder machine has one rotating screw, while a twin-screw PVC extruder machine has two intermeshing screws. Twin screw machines are generally used for processing a more comprehensive range of materials and achieving better mixing and output quality. Q: What are the critical components of a PVC extruder machine? A: The