.jpg)

LESUN specializes in manufacturing quality and high precision extruder spare parts, including twin screw extruder parts, screw barrels, screw shaft, etc. Ten years rich experience, advanced processing ways and strong technical ability. Wide selection of extruder spare parts to meet your needs. RFQ today!

We know extruders, and make equipment to last, from table top models that are ideal for small runs, testing and training to warehouse-sized extruder machines. With twenty years of industry leadership, we design and produce the most reliable and efficient extruders, dies and associated equipment available.

Jan 17, 2024 · Applications of Extruder Machine. Extruders are versatile machines used across various industries. In construction, they produce piping and insulation materials; in automotive, they create components and trims; and in consumer goods, they are used for everything from plastic bags to intricate toys.

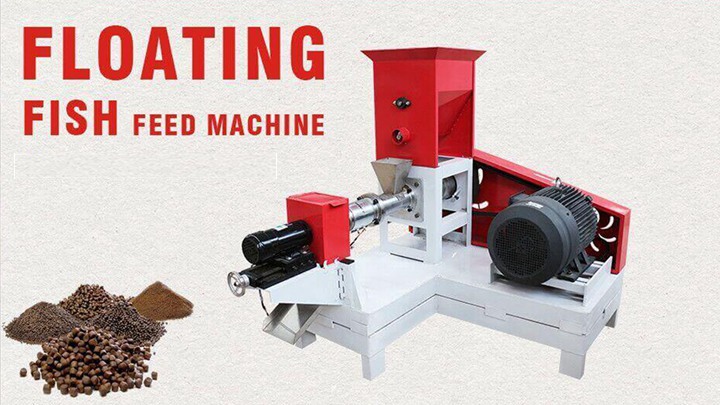

Poultry Feed Pellet Machine in Botswana: As the poultry industry grows, this machine ensures that birds, whether broilers or layers, receive a balanced diet. Fish Feed Pellet Machine in Botswana: With the growth of aquaculture, especially in local dams, this fish feed pellet machine machine in Botswana is making waves in producing aqua-specific

.jpg)

Dec 1, 2021 · Thus, a single screw fish feed extruder was designed and fabricated with locally available and affordable engineering materials. The machine's performance was evaluated with constant feed

.jpg)

Thus, a single screw fish feed extruder was designed and fabricated with locally available and affordable engineering materials. The machine s performance was evaluated with constant feed moisture, constant feed rate, and constant screw speed, while the multi-channel dies were varied for 2, 4, 6, and 8 mm.

.jpg)

The ANDRITZ single-screw extruder type EX1021 represents state-of-the art technology, ensuring unique quality feed at minimum operating costs.

Dec 26, 2023 · Components of Extrusion Machines. Extruder: The heart of the machine where plastic is melted and pushed through a die. Die: Shapes the molten plastic into the desired profile. Cooling System: Solidifies the extruded plastic. Cutter: Cuts the profile into desired lengths. Key Factors to Consider When Buying 1. Machine Type and Size

Jan 20, 2024 · The essence of this improvement lies in the strict control of the weight per meter of the product during the extrusion, directly influencing the quality of the extruded product. Previously, standard extrusion machines lacked precise control devices for this measure, leading to variability in product quality.

.jpg)

Sourcing Guide for Feed Extruder Machine: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: floating fish feed machine, fish feed machine, pet food making machine.

.jpg)

Cold extrusion machines do not. Some hot extruders also provide hot spinning, the forming of metal parts from a flat, rotating disk that applies controlled pressure to one side and causes the metal to flow against a rotating male form. Specifications. Selecting extrusion machines requires an analysis of extruder screws, barrels, and tips.

.jpg)

Dec 28, 2023 · Compound screw extrusion system 1—hopper; 2—extruder; 3—machine head; 4—blowing needle; 5—mold; 6—tube blank. An extruder screw, also known as a “plasticity,” is a critical component of plastic extrusion machinery.

Jun 22, 2022 · 400kg/h fish feed extruder machine parts Feed size 5 mm south Africa. 300-400kg/h Floating Fish Feed Pellet Extruder Feed Pellet Making 300-400kg/h Floating Fish Feed Pellet Extruder Feed Pellet Making Machine Price Model :LM90 Capacity (kg/h):300. Tel : +8619337889051 Whatsapp: +86 19337889085 Email :lima37@limamachinery.com .

Dec 12, 2022 · The operating cost of fish feed production decreases with the increase of the screw speed, feeding rate and die hole dimeter, the costs of extrusion processing ranged from 0.628 to 1.081 LE

Nov 1, 2023 · For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.