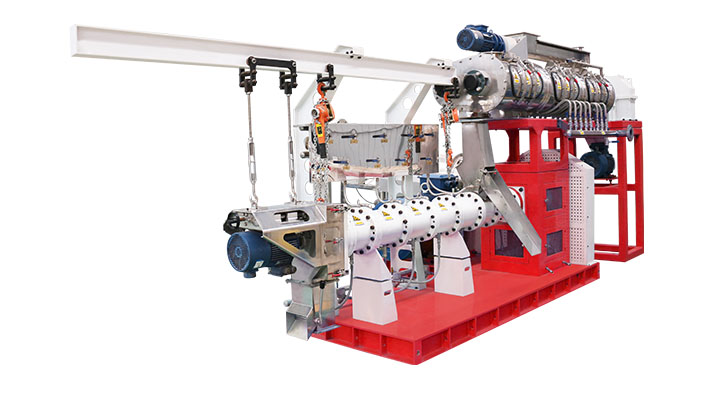

Dec 12, 2022 · To achieve that, the extruder productivity, total losses percentage, energy consumption and cost per kg of feed were studied at three different screw speeds for main motor of extruder (200, 250

.jpg)

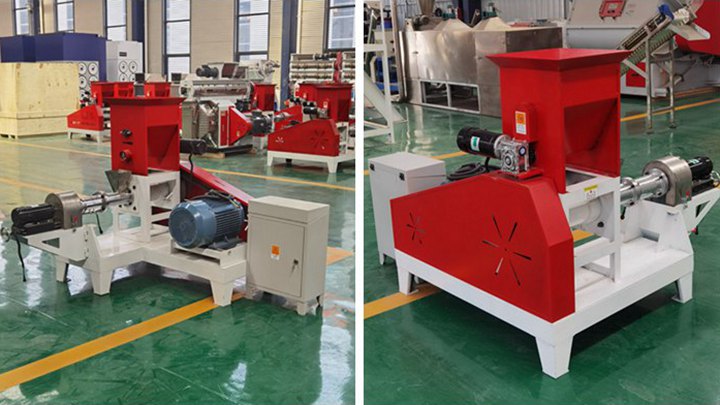

large scale fish feed making machine in South Korea. fish feed extruder machine supplier,fish feed extruder Shrimp Feed Pellet Plant Production Line, - Richi Machine 1.Determine the scale of shrimp feed mill. 2.Determine the feed pr Email: lima37@limamachinery.com Tel: 8619337889051. Get Price.

fish feed pelleting machine in the philippinesFloating Fish Feed Mill Extruder for Philippines Aquafeed -. Main cultured aquatic species in Philippines are milkfish, tilapia and b Tel:8619337889078

small scale Biofloc Fish extruded feed machine in the Philippines-Fishfeedextruders. small scale feed production line growfin fish feed PhilippinesIts specifications range from 100-500kg/h small fish feed line to 1-4 tons large-scale complete aquatic production li. Email: lima37@limamachinery.comTel: 8619337889051. Home.

.jpg)

Sep 22, 2023 · All Baker Perkins parts carry a 12-month warranty: they have the re-assurance of full process and technical support from the Original Equipment Manufacturer. SBX Master™ extruders. Screw parts. Extruder screw parts are made using the original drawings to ensure effective operation.

.jpg)

What Does a Plastic Pipe Extruder Machine Do? The pipe extruder machine, is the most important part of any pipe production line; it heats, mixes, and extrudes fesh pipe. A good extruder will ensure that you consistently produce quality pipe, allowing you to save money on scraped pipe and differentiate yourself from the competition.

.jpg)

ACQUIRED ADDITIONAL EXTRUSION PRESS AND GOING INTERNATIONAL. The year 2010 marked two (2) milestones for CALCO INDUSTRIES INC. It acquired the 5″ Yen Sun 1100 US Ton to accommodate additional demands. The machine is more technologically advanced with higher efficiency levels.

Biofloc Technology For Fish Farming – Amy的博客2020/07/13 · Biofloc fish farming, is a biofloc technology for fish farming. Fish feed extruder is the indispensable equipment to ma +8619337889051

.jpg)

Dec 1, 2023 · A: Some critical components of a plastic extruder machine include the feed throat, breaker plate, barrel, screw(s), and die. These components work together to melt, shape, and form the raw plastic material into the desired product. Q: What are the advantages of using a plastic extrusion machine?

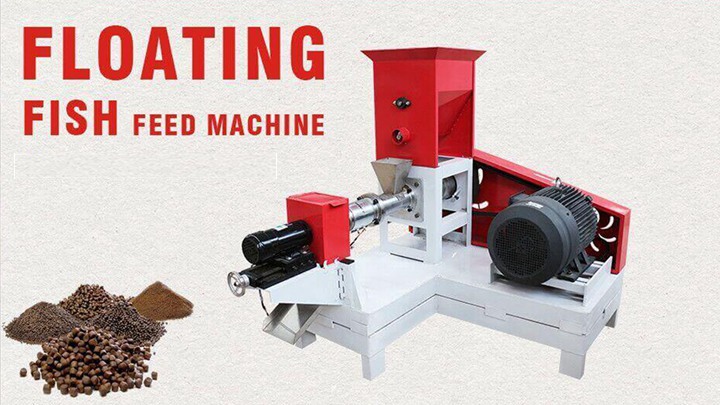

The pressure difference in the interior of extruder and the external environment will cause the extrusion of the aquatic feed. Notice: Dry type feed extruder for dry extrusion and wet type feed extruder for wet extrusion. 4. Drying Fish feed pellets from pellet making machine need to lower high moisture and temperature.

Commercial fish feed extrusion process refers to cook the mixture of feed ingredients under high temperature, moisture and high pressure by means of fish feed extruder within short time, whereby the high temperature is a direct result of friction (dry extrusion) or preconditioning and steam injection (wet extrusion).

The EX Series of single screw extruders represents state-of-the-art technology, ensuring unique quality feed at minimum operating costs with a high degree of processing flexibility Watch our product animation to see the EX Series in action and download the datasheets for technical details, sizing, and options.

One key focus is support for local feed production, made easier by fish feed making machines. This initiative aligns with the country wider agricultural and economic objectives. By recognizing and harnessing the growing importance of fish farming, the Philippines is well on its way to achieving a sustainable and profitable aquaculture industry.

Dec 26, 2023 · Components of Extrusion Machines. Extruder: The heart of the machine where plastic is melted and pushed through a die. Die: Shapes the molten plastic into the desired profile. Cooling System: Solidifies the extruded plastic. Cutter: Cuts the profile into desired lengths. Key Factors to Consider When Buying 1. Machine Type and Size. Criteria

Email : lima37@limamachinery.com. 8619337889051. Home