Extruder Machine [Everplast Wiki]2019/08/13 · Extruder Machine. Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuo Tel:8619337889051

CJWH series twin-screw extruders mainly focus on middle level customers with improved requirement for quality and efficiency.This series machine equipped with local made middle torque & high speed gearbox, the technology, configuration, performance and quality in the domestic leading level with competitive efficiency.

Twin Screw Extruder Machine For Masterbatch Production 400-500kg/Hr OutputContact Now. 65mm High Torque Twin Screw Extruder for masterbatch production line twin screw extruder will help you produce color masterbatch. We have full experience in producting plastic pellet extruder, and we are Read More. 2020-05-26 17:40:05.

.jpg)

500kg/h twin screw extruder Indonesia fish feed making machinewe buy weight checker machine use by spray sistem, good accurate, quick move on the production check —— Efa-Indonesia

.jpg)

Benk twin screw extruder machine is used the best parts from the Chinese manufacturer and some are produced by ourself, the quality is best among all China extrusion suppliers. The elements what we buy from local suppliers are gearbox, screw and barrel, ABB inverter, contactor and motor. Benk conical twin screw extruder’s principle is using

We have made a list of trusted Extruder Machine suppliers in Zambia that you should consider in your shortlisting process. Use Getatoz to find the best Extruder Machine suppliers in Zambia for your need. We've helped thousands of businesses choose the right Extruder Machine suppliers in Zambia. We believe the above list will be an excellent

.jpg)

Fish Feed Machine . Fish Feed Production Line . Poultry Feed Machine Brand new feed production line goose Ecuador . Position : Home » Blog » Fish Feed Machines » Brand new feed production line goose Ecuador. CLOAK - Hidden in plain sight. This is our clothing brand.

The ideal combination of very high specific torque (up to 15 Nm/cm³) and a large volume (OD/ID = 1.66) in one extruder - this is the feature which makes the ZSE MAXX twin screw extruder stand out. An extremely large range of processes benefits from the maximal adaptability of the ZSE MAXX since it has high process engineering relevance. As a

.jpg)

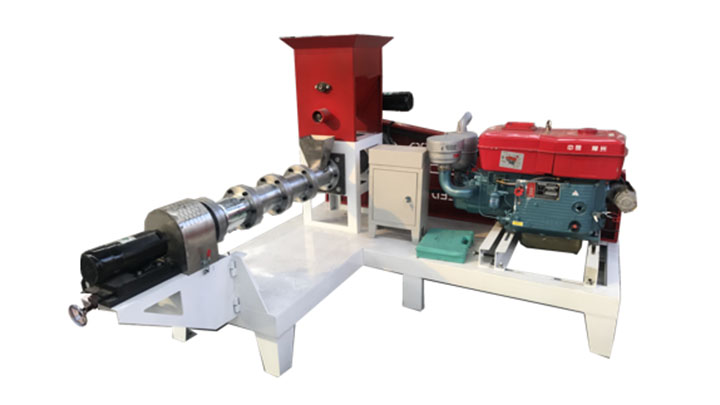

locally made feed extruder machine fish NamibiaHome » Blog » Fish Feed Machines » locally made feed extruder machine fish Namibia 2000kg/h floating fish feed extruder Feed size 7 Tel:8619337889051

.jpg)

locally made Sunfish twin screw extruder machine in Zambia Sunfish twin screw extruder machine price-Feed Pellet Machine2019/05/13 · May 13, 2019. Twin Screw Extruder is a machine which has two closely intermeshing and self-cleaning ident Email: lima37@limamachinery.com Tel: 8619337889051

.jpg)

Koi/Carp feed machine for the startup-Fish Feed Making Machines 4.Pellet size from diameter 0.9mm-15mm just by changing the mould. 5The machine can make floating and sinking fish feed.For the float time,it can floating over 12 hours. 6.The machine also can make feed for pet with different shapes and we can customized the shape for you. 7.We can provide whole fish feed pellet production line.

.jpg)

locally made Sunfish twin screw extruder machine in Zambia Sunfish twin screw extruder machine price-Feed Pellet Machine2019/05/13 · May 13, 2019. Twin Screw Extruder is a machine which has two closely intermeshing and self-cleaning ident Email: lima37@limamachinery.com Tel: 8619337889051

.jpg)

Sunfish twin screw extruder machine price-Feed Pellet Machine2019/05/13 · May 13, 2019. Twin Screw Extruder is a machine which has two closely intermeshing and self-cleaning ident Email: lima37@limamachinery.com Tel: 8619337889051

.jpg)

Koi/Carp twin screw extruder machine low costQuality Twin Screw Extruder & Single Screw Extruder 35mm Normal Torque Twin Screw Extruder / Masterbatch Production Line 20-50kg/hr. B +8619337889051 Email: lima37@limamachinery.com

Twin-screw extruder is the core of this line, enabling the continuous production of expanded fish feed. 2. Processing line description 2.1 Flow chart: raw materials→ extrusion→ drying→ flavoring→ cooling→ packing 2.2 Processing line features 2.2.1 High work efficiency, automation degree, materials usage, application range.