.jpg)

Introduction. Understanding the fish feed extrusion process is crucial for anyone in the aquaculture industry. Whether you’re a manufacturer, supplier, or a fish farm owner, knowing how extrusion works can significantly impact your operations.

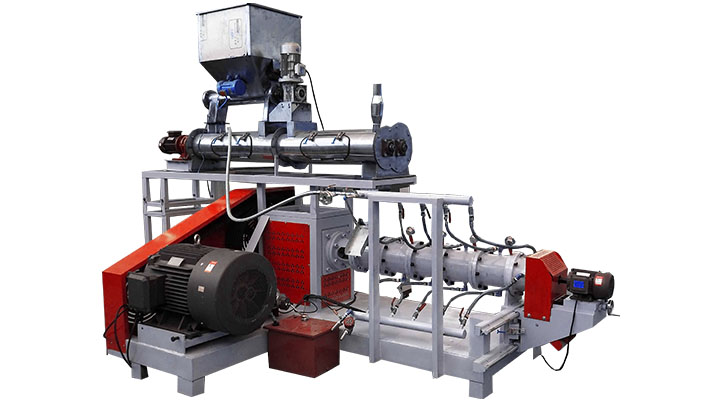

The complete floating fish feed production line encompasses a fish feed pellet machine, crusher, mixer, dryer, and essential equipment. It processes ingredients like corn, soybean, wheat, protein, and fish meal into nutrient-rich pellets.

Fully automatic industrial floating fish feed production line sinking fish feed extruder sinking fish feed processing line $12,500.00 - $29,000.00. Min Order: 1 set.

The floating fish feed production line is an aquatic feed processing system specially designed for extruded feed, and is suitable for the processing of various types of extruded aquatic feed, pet extruded feed, and livestock and poultry extruded feed.

.jpg)

As an important factor in scaled fish farming and aquaculture industry, fish feed production has a big effect on both fish growth efficiency and fish farming cost. Since the past decades, there has been an obvious increase in the use of floating fish feed because it is a kind of high-quality environmental-protection fish feed with superior water stability, better-floating properties, ease of

.jpg)

Single screw fish feed processing line can be divided into 2 types: Small Dry Type Plant and Large Wet Type Plant, in accordance with what extruder you choose. WET TYPE: Super automation control and high production efficiency, it is the best choice for medium and big sized feed mills and breeding farms.

.jpg)

Philippines 1200-1500 KG/H Floating Fish Feed Production Line Iraq DGP-120 500-600 Kg/h Fish Feed Pellet Machine Project Nigeria 1.8-2 T/h Fish Feed Pellet Mill Extruder

.jpg)

May 12, 2023 · A floating fish feed production line is an advanced and efficient system used for manufacturing high-quality and nutritious fish feed pellets. It includes several stages, such as handling and processing raw materials, extrusion, drying/cooling/packaging of final products and more. One of the key advantages of floating fish feed production lines

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run.

This floating fish feed production line adopts fish meal, corn powder and so on as raw materials. This line can be adjusted to produce various shapes of fish feed, shrimp feed and so on. Many production capacities can be chosen according to specific requirements.

.jpg)

Process flow. Raw materials for extruded floating fish feed plant: corn, rice bran, soya meal, wheat flour, fish meal, blood meal, fish oil, mineral premix, vitamin

.jpg)

Floating fish feed production line ,small fish food plant Pellet size : 0.9mm~15mm Application : Catfish,tilapia, shrimps, gold-fish, tropical fish,dog,cat,bird,etc Raw materials : Cereal,corn,wheat,barley flour, oil seed meal/cake,edible leaf, fish meal, bone powder,etc Floating fish feed production line is applicable to fish farms, fish feed

Floating Fish Feed Production Line What is sinking fish feed? Sinking fish feed is a type of fish food specifically designed to sink to the bottom of a water body, whether it’s an aquarium, pond, or lake.

•1. Nutritional content of the feed is guaranteed (you can exactly know the nutritional level of the feed), •2. there is no change according to the season of the year, •3. You can buy it whenever you want from fish feed plants, •4. It is easy to store the feed.

.jpg)

50-150 kg/h Fish Feed extruder production Line 200-500kg/h Fish Feed production Line 200-1000kg/h Chicken Feed Pellet Line