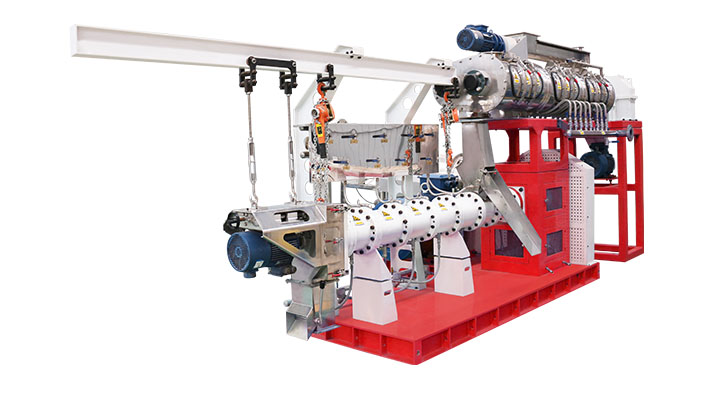

Twin-screw fish feed extruder adopts high machine barrel quality screw and suspension design with the international vanguard technology to reduce the friction between machine barrel and screw. It is much more extensive and economical than single screw extruder machine.

.jpg)

Soft bites, unique shapes, varied sizes and applications. Create all types of treats that are popular with pets and pet parents. Wenger's Thermal Twin Extrusion technology is the most effective and proven system to produce kibble with high fresh meat inclusion. The Thermal Twin's creative screw geometry, along with an innovative method of high

.jpg)

Our range of floating fish feed machine products include 1.5-12t/h floating fish feed extruder, twin screw extruder machine, single screw extruder machine, wet screw extruder machine, and all auxiliary equipment for floating fish feed processing systems.

A twin screw extruder machine serves various industries, such as plastics, floating fish feed processing, and animal feed manufacturing. Unlike a single screw extruder machine, it has two intermeshing screws that rotate within a barrel, offering specific advantages and applications.

.jpg)

Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste.

.jpg)

Twin screw food extruder has greater friction performance than single screw extruder, so they have better puffing capabilities and are suitable for high-humidity extrusion processes. Suitable for various low-viscosity or high-viscosity raw materials.

Thermo Scientific twin-screw extruders offer flexible compounding configurations that can move you from small-batch, lab-scale extrusion to pilot-scale production. With lab-scale twin-screw extruders, you can: Simulate production and optimize your process; Feed different additives (solid and liquid) along the various barrel ports