.jpg)

2021-09-28 · 1. Fish feed production line equipment is widely used for making feed pellets for fish, shrimp, crab, eel, catfish, etc. in medium and large aquaculture plant.It can also make feed pellets for pets, like cat, dog, rabbit, etc. 2.

.jpg)

The extrusion equipment for fish feed production can adjust the process parameters such as raw material, temperature and moisture, so that the fish feed has the characteristics of long floating time, hard to disperse, novel shape, unique taste, rich nutrition and delicate organization, which is suitable for different fish tastes.

Key Features to Look For. When choosing the right fish feed pellet machine, consider the machine’s efficiency, reliability, and durability. An efficient machine will consume less energy and produce more pellets per hour, which can significantly reduce your costs in the long run.

.jpg)

Fish Feed Production Systems. We classified feed types in two groups: 1. Moisture Feeds. 2. Dry Feeds (Pellet and Extruder Feeds) Made by non economic fish species. The main principle is grind and mix and then feed the fish.

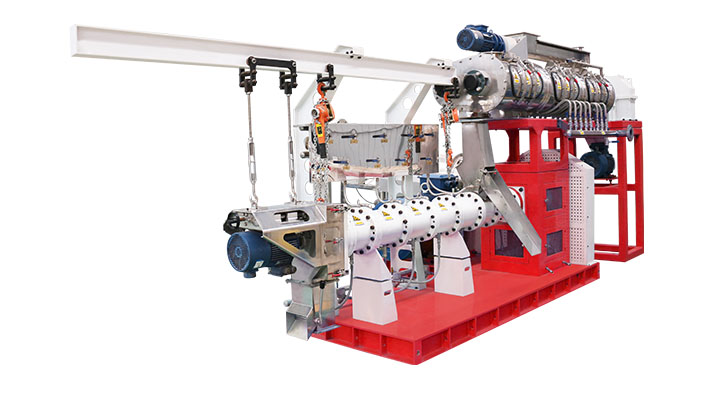

1.5-2T/H extruder machine for fish feed. The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds.

Brand: Product Code: Model: ZC160 Brief: 1.The mill is designed to manufacture animal feed pellets and high-density biomass pellets with raw materials of grains,sawdust, straw, rice husk and tree bark, etc. 2.the die plates and pressure rollers are made by 40Cr alloy steel,their average service live is 800 hrs.The aperture of the die plate is between 2.5mm---10mm. 3.the moisture of the raw

.jpg)

Maintenance Tips for Floating Fish Feed Extruder Machine. Regular Cleaning: Over time, remnants of feed can stick to the fish feed making machine.Regular cleaning ensures longevity and optimal functioning.

.jpg)

May 22, 2017 · This Best selling livestock feed grinder machine is smashing equipment for processing block material or rod -like material in to forage and animal feeds. it is mainly suitable for corn, corn stalk, peanut shell, bean stalk and so on.the feed grinder machine working principle is material from the hopper into the crushing chamber, there have been

The floating fish feed machine processes various materials with capacities from 30kg/h to 5000kg/h. Small-scale machines range from 30kg/h to 1000kg/h, ideal for small farms, home use, or small factories.

.jpg)

wire electro-discharge techniques enable complex extruder dies to be machined in one or two component assemblies. This prevents problems of leakage during production and damage during disassembly and assembly. 3

Nutritional Aspect on Fish Feed Making Machine in Philippines. Adequate nutrition is critical for optimal fish growth. Fish feed making machine in Philippines offer precise control over the ingredients, ensuring to meet the nutritional needs of various fish species.

.jpg)

Apr 1, 2004 · Extrusion cooking involves the application of mechanical energy supplied by the shearing and mixing action of the extruder screws. During the process, a formula mix is transformed from a powdery, free-flowing meal into a dense, compact powder.

.jpg)

Jul 20, 2022 · With the rapid development of the tank farming sector, traditional farming techniques have been far from meeting people's needs. The needs for aquaculture fish feed made by fish feed extruder device are not only balanced nourishment, great stability of the feed in water, no pollution to water high quality, etc, and a lot more rigid demands are put forward for the ecological quality of fish

.jpg)

Jul 14, 2023 · Effect of extrusion process parameters on pellet crumbliness in fish feed production. July 2023; Potravinarstvo 17:594-605; DOI:10.5219 Fish feed extrusion cooking includes process-independent ...

.jpg)

Fig. 1: A variety of feeds can be manufactured with extrusion systems. Growth in aquaculture production has sparked demands for increasing quantities of processed feeds, as well as a broad range of feed characteristics to accommodate the vast spectrum of species now cultivated.