.jpg)

Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste.

Our range of floating fish feed machine products include 1.5-12t/h floating fish feed extruder, twin screw extruder machine, single screw extruder machine, wet screw extruder machine, and all auxiliary equipment for floating fish feed processing systems.

The basic function of fish feed produced through the extrusion process is to kill the germ, mycete, and fungus in feed ingredients, improve the hygienic quality, and provide safe fodder for fish and other aquatic animals.

.jpg)

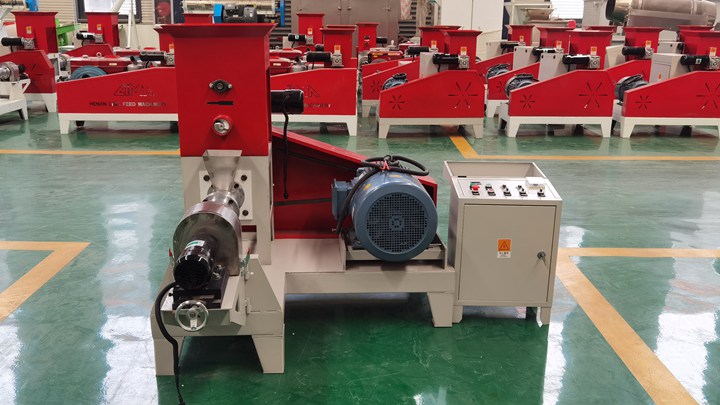

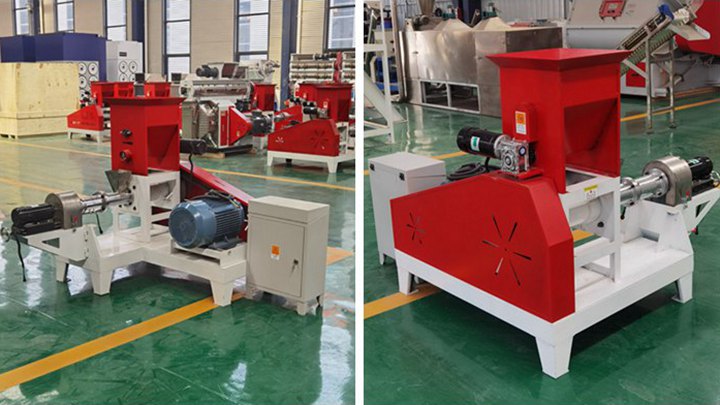

DGP Fish Feed Extruder Machine. Twin-screw Feed Extruder. Service: Customized & OEM. Cooperation: Factory Directly. Brand: Herm®. Application: poultry, livestock, ruminant,cattle, sheep, pig, goat, fish, shrimp, crab, aquatic, etc.

The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity.

Fish feed extrusion is a way to make fish food pellets that are good for fish and easy to digest. This method changes a mix of feed ingredients into dough, which then goes through a machine called an extruder.

.jpg)

The new RCPH120*2 feed extruder machine adopts the steady-state screw combination technology, which is more conducive to the improvement of the production capacity of aquatic feed and the production of freshwater buoyant fish feed.