.jpg)

Europe / UK Pellet Mill Supplier. Kesir is a leading supplier of pellet mills, biomass densification, drying and grinding systems in the UK, Europe and beyond! To view our North American Pellet Mills site, please click here. We offer peace of mind, with modern and innovative initial designs and layout. Our systems are heavy duty, built to the highest quality, using the best materials available.

.jpg)

Small farm using animal feed pellet production line with 1 t/h output May 24, 2016 ... Small farm using animal feed pellet production line with 1 t/h output ... 1 t/h simple animal feed pellet production line for poultry /chicken /cattle/sheep/ pig feed ... It consists of screw elevator, machine set ( 9 FQ feed grinder and...

.jpg)

It is a good choice for farm and those poultry feed plant pellet production line manufacturing cattle our poultry feed production line has wide applicable scope It can process different materials such as corn, maize, grass, grain, SBM, MBM, alfalfa, molasses, Small Feed Pellet Line - GEMCO EnergySmall feed pellet line is also called mini feed

.jpg)

Farm Use Feed Pellet Production Line , Find Complete Details about Farm Use Feed Pellet Production Line,Feed Pellet Line,Animal Feed Pellet Production Line,Complete Animal Feed Pellet Production Line from Feed Processing Machines Supplier or Manufacturer-Henan Nkun Machinery Co., Ltd.

.jpg)

Application: for making cattle, geese, pig, duck, chicken, sheep, rabbit, and other animals, livestock and poultry feed.Such as 2-4mm diameter chick feed pellets and pig feed pellets.2-5mm rabbit feed pellet, 4-8mm cattle or sheep feed pellets. The last pellet length can be adjusted.

.jpg)

Application: Fish oil,Fishmeal,Soya protein,Wheat gluten,Wheat and peas, etc. pellet dia: 0.9-10mm. customized. 60-5000kg/h. 1 year. Make feed pellets for all kinds of fishes, suitable for fish pond holders and feed pellet manufacturers. 200-300kg/h Small Feed Pellet Line. Get Free Quote!

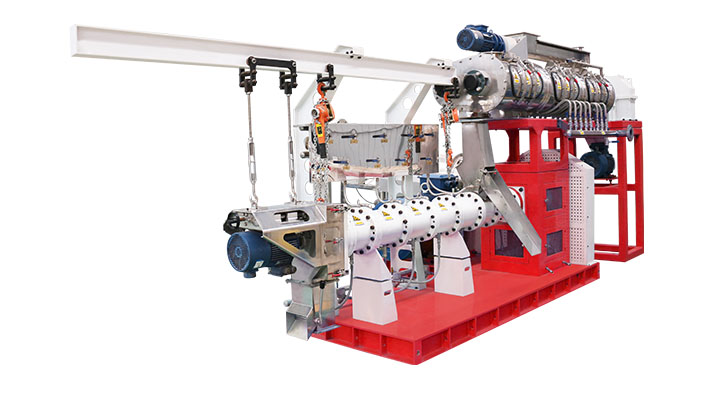

Total 220kw Feed Pellet Production Line With SKF Bearing Capacity 10T/H. Line name:Large Feed Factory Use Feed Pellet Production Line With SKF Bearing. Application:Animal Husbandry factory. Total power:550kw. Pellet size:0.9-15mm

Feed paddle mixer is a horizontal mixing device widely used for mixing grain powder in feed pellets production line. Short mixing period, 30-120s is enough for every batch of material. High homogeneous degree, CV ≤5%.

There are also many biomass pellet mill manufacturers outside UK, among which GEMCO is a representative who is reputable for its high quality and favorable price equipment. GEMCO began its pellet mill manufacturing business in 2000. GEMCO Pellet Mill is hot sale both domestically and internationally, especially in UK. Small Pellet Making Machine.

.jpg)

Feed Pellet Production Line sales8@zgshuanghe.com 2021-05-13T17:27:11+08:00 Feed pellet production line is a complete set of machines that are specifically used to make feed pellets. The key machines like hammer mill, feed mixer and feed pellet machine are patented product through 10 years research and development combined with advanced

livestock farm use 1-2 t/h mini ring die type feed pellet production line Xinxiang Hengfu Electronic Machinery Co., Ltd. 1 Set (Min. Order)

.jpg)

Farm Use Feed Pellets Line, Poultry Feed Pellet Production Line, Find Details about Poultry Feed Pellet Production Line, 1.5-2t Poultry Feed Pelleting Mill from Farm Use Feed Pellets Line, Poultry Feed Pellet Production Line - Zhengzhou Leabon Machinery Equipment Co., Ltd.

1 T/H Capacity Feed Pellet Production Line 2 - 12mm Pellet Size Electric Control Contact Now 2 - 12mm Pellet Size Animal Feed Manufacturing Plant / Chicken Feed Making Machine

.jpg)

Quality Animal Feed Production Line & Feed Pellet Poultry Feed Pellet Production Line 0.9-12mm With Crumbler Machine Double Steam Conditioner; Forage Animal Feed Production Line , Electronic Control System Animal Feed Equipment; Total 220kw Feed Pellet Production Line With SKF Bearing Capacity 10T/H; 1-2.5 T/H Animal Poultry Pellet Feed Plant For Small Farm Factory Power 50kw

The average pellet production line price will vary depending on the size of the machine, which components are included, and what kind of raw material you are planning on processing in it, among other variables. However, you can generally expect to pay around $2000 to more than $400000 US dollars for a machine.