Total 220kw Feed Pellet Production Line With SKF Bearing Capacity 10T/H. Line name:Large Feed Factory Use Feed Pellet Production Line With SKF Bearing. Application:Animal Husbandry factory. Total power:550kw. Pellet size:0.9-15mm

.jpg)

Small Poultry Feed Pellet Plant designed for Farm Use This small poultry feed pellet plant with capacity 400-600kg/h is ideal for small raw materials into required size for further processing in poultry feed production.

Good Team. Shandong Yulong Machinery Co., Ltd. was founded in 1998 and produced the first centrifugal high-efficiency granulator in 2008.After more than 20 years of development, it has become a globally competitive pellet machine manufacturing company with crushing and drying technology and comprehensive solutions.

.jpg)

livestock farm use 1-2 t/h mini ring die type feed pellet production line Xinxiang Hengfu Electronic Machinery Co., Ltd. 1 Set (Min. Order)

Cow Food Animal Feed Pellet Used As A Feed For Cows, Sheep, Horses, And Other Animals: INR 1000.00: Animal Pellet Feed, Its Gives Cattle Extra Nutrients And Increase Milk Productivity: INR 23.00: 100% Organic Animal Pellet Feed For Increase Milk Productivity, 1 Bag: INR 1050.00: Feed Pallet Mill 10HP: INR 130000.00: High Nutrition Cattle Feed Pellets : INR 22.00

.jpg)

New animal feed pellet mill, feed pellet mill line, animal food pellet production line: 1 Set : US$1087: US$6999: Factory directly sale ce animal feed pellet mill /pet food pellet production line: 1 Set : US$1101: US$5307: Feed Pellet Machine Animal Pet Food Production Line: 1 Set : US$1632: US$7993: Poultry animal feed production line machine

.jpg)

Sunwit Industry provides a comprehensive, systematic and high-quality solutions for agriculture, husbandry, and biomass industry. learn more. case. 11. 2020/08. New Zealand 600-800Kg/H Small Animal. 29. 2020/05. Kenya 2-3T/H Chicken Feed Production.

.jpg)

Small Scale Animal Feed Pellet Production Line. This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the

.jpg)

cattle feed Buy Offer India Business Directory providing cattle feed Buyers Importers in Animal Feed Production Line / Silo Project / Organic Fertilizer Line a Large Selection of Cattle Feed Products at cattle feed plant ,cattle livestock ,cattle... LEARN MORE. How to buy a pellet mill online (main suppliers review ... Aug 3, 2014 ...

Poultry Feed Pellet Production Line 0.9-12mm With Crumbler Machine Double Steam Conditioner; Forage Animal Feed Production Line , Electronic Control System Animal Feed Equipment; Total 220kw Feed Pellet Production Line With SKF Bearing Capacity 10T/H; 1-2.5 T/H Animal Poultry Pellet Feed Plant For Small Farm Factory Power 50kw

Qatar 1-1.2T/H Pigeon+Camel Feed Pellet Production Line Region: Asia Product type: feed. CONTACT US Mob: 0086-185-74103366 Fax: 0086-371-63752859

.jpg)

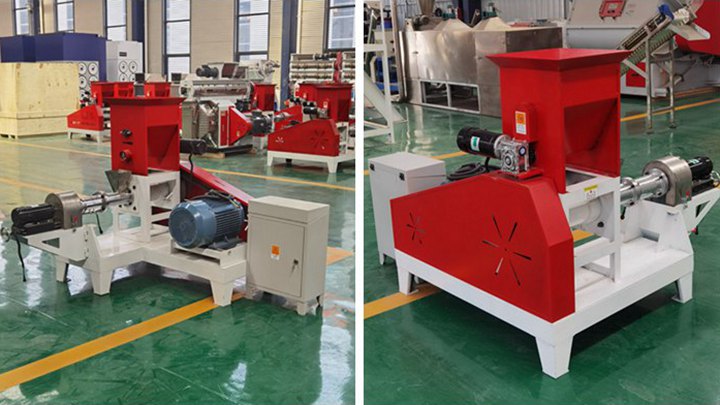

The complete set of animal feed pellet production line is designed with transmission, mixing and pelletizing, so it is easy to operate it due to its simple and complete structure. The pellet machine adopts SPB powerful and narrow belt transmission system, which has ideal transmission efficiency, stable rotation, high output, low noise, no oil

Proper steam of good quality is required for better performance of machines and production of quality feed. Steam parameters required are: 1. Dry Saturated Steam Minimum 8.5-9 kg/cm2 at the boiler. 3. Good & reputed make boiler, Water softener. 4. Proper Steam traps, insulation of steam line and supporting valves.

Poultry feed pellet mill is an ideal pelletizing machine for high quality feed pellets. Before pelletizing, grains such as corn, wheat, rice and soybean etc. need to be crushed into powder.

Livestock, cattle, sheep, cow, pig, camel, deer, rabbit, Alpaca, etc. is raised by people for meat, eggs, milk, leather, fur, and wool. Many of these livestock animals can be fed with feed pellets, as feed pellets have higher nutrition density, more comprehensive nutrition, higher economic benefits (animals can digest, absorb and conserve better) and are easier to store and transport than