Small Scale Animal Feed Pellet Production Line. This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the

.jpg)

120A Household Pellet Mill. As the smallest model of diesel pellet mills,120A pellet mill is very convenient to move around. Proper for small scale pellet production at home, on the farm, in the yard or outside in the open air.

According to research and experiment, the stationery rollers with rotating die type is the best to make animal feed. Flat Die Feed Pellet Mill Features and Application: 1. Driven by electric motor is more energy-saving and environmentally friendly. 2. Both the rollers and the flat die have passed wear-resistant process.

The STLP400 small mobile feed pellet plant is a complete feed processing production line developed by GEMCO company for domestic and foreign livestock and poultry farmers, farmers, rural cooperatives and feed manufacturers, able to meet the complete formula feed and grass feed for chicken, livestock, cattle, sheep and other animals production.

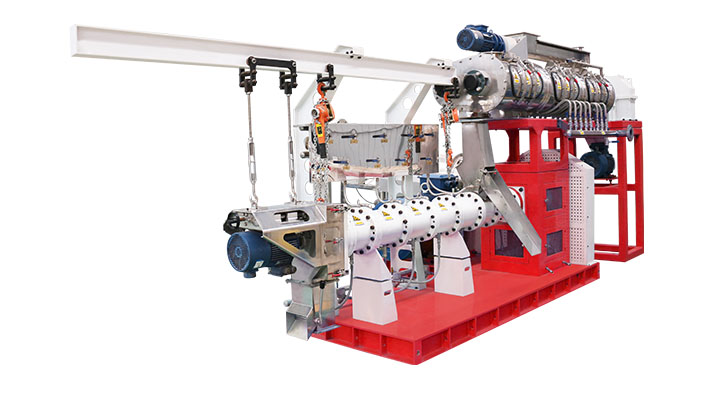

600~1000kg/h Small Animal Feed Pellet Production Line. Small Complete Set of Feed Processing Machine for Making Pelleted Feed. Production Output: 600~1000kg per hour. Diameter of Feed Pellets: φ1.5~φ8mm. Diameter of Pellet Die: φ250mm. Main Equipment: Ring Die Feed Pellet Mill, Mixer and Conveyors. Application: Make feed pellets for

.jpg)

The Flat die Pellet Mills have a stationary die with a rotating roller. The raw material drops down into the pellet chamber where it is then compressed between the rollers and die to form pellets by going through the die holes. Benefits of Flat Die Pellet Mill: Due to their structure, these pellet mills are light and easily transportable

.jpg)

Advantage. Cattle feeding machine made the feed pellet by corn, bean pulp, straw, grass and rice husk. Flat die adopt high quality wear-resisting alloy steel, which are processed by special heat treatment, high hardness, long working life. It is recommended replace roller and die at the same time. We have several diameter for your choice, and

.jpg)

Oct 01, 2015 · 2015-10-01. Technical Guide. 1 Comment. This beginner’s guide has been produced to help provide an introduction in to the world of pellet production. The guide will discuss the benefits of pellets and how they are produced. It will also discuss the differences between pellet mills, and the skill required in quality pellet production.

Commerical Use Automatic Chicken Feed Pellet Production Line 1-2t/h Animal feed pellet mill machine Line 100~1000KG/H 1-18t/h Ring Die Poultry Feed Machine by Electric 60-1000kg/h Flat Die Poultry Feed Machine by Electric/Diesel Engine

.jpg)

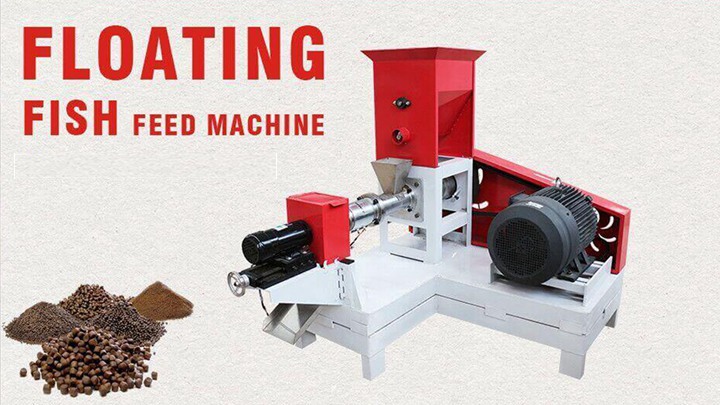

customized. 60-5000kg/h. 1 year. Make feed pellets for all kinds of fishes, suitable for fish pond holders and feed pellet manufacturers. 200-300kg/h Small Feed Pellet Line. Get Free Quote! 400-600kg/h Feed Pellet Production Line. Get Free Quote! 800-1000kg/h Feed Pellet Production Line.

.jpg)

Sep 25, 2020 · Cattle Feed Pellet Production Line Equipment. 1. Alfalfa crusher. 2. Mixer. 3. Ring Die Alfalfa pellet machine. 4. Cooling system. 5. Screening system. 6. Packaging system. 7. Dust removal system. 8. Transportation system. Alfalfa pellet mill, called lucerne pellet machine in South Africa, is used in many animal feed pellet production lines.

Project Name: STLP300 cow feed pellet plant in South Africa. Capacity: 600-800kg/h. Raw Materials: 47.5% maize/corn, 35% wheat stalk powder or grass powder, 10% cottonseed meal, 5% wheat bran, 1% additive, 1% bone powder, 0.5% salt. Purpose: making complete diet cow feed pellets. Machines in this feed pellet plant: crusher, mixer, screw conveyor, storage bin, feeder, ZLSP300 feed pellet mill, pellet cooler, deduster, electric control cabinet.

.jpg)

Aug 25, 2018 · 3.The farm-use one has simpler structure, lower price and maintenance cost than the industrial-use one, so it is a good choice for users that have limited investment budget. 4.The pellet produced by the farm-use one has a diameter of 1.5-12mm, and the pellet produced by the industrial-use one is 2-10mm, so the farm-use one can meet a wide

.jpg)

By doing this, you can form a large scale production line, which can work with high efficiency. The production line equipment should consist of fertilizer compost machine, crusher, mixer, automatic fertilizer dispenser, pellet polishing machine, rotary drum dryer, cooler, coating machine, packing machine, etc. Flat Die Pelletizer. Get A Free Quote

May 15, 2020 · Flat die feed pellet production line shipped to Tanzania feed factory Date: 05/15/2020 08:53:15 From: feed-pellet-plant.com Clicks: Kindly Reminder: If you are interested in our products, Please get in contact with us