Technical Parameters of main equipments for 1-2t/h poultry feed pellet production line: No. Product: type: Power(KW) 1.Raw materials receiving and crushing and mixing

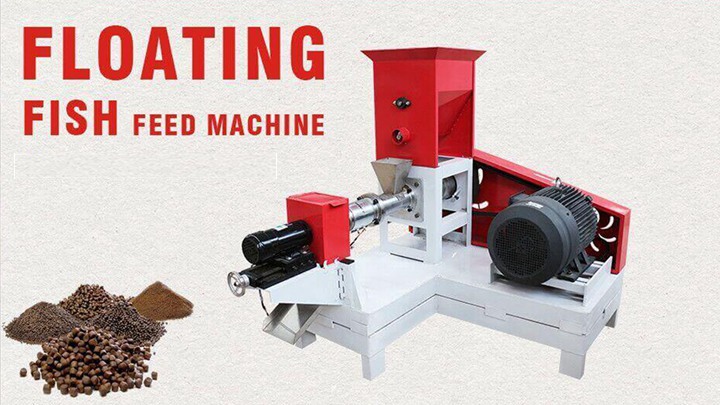

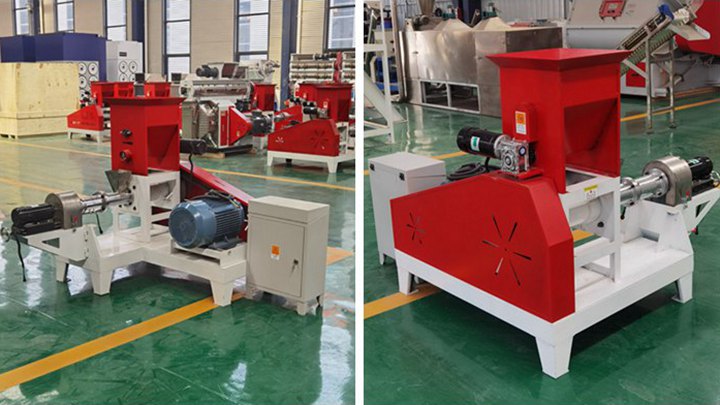

1-1.2t/hfish pellet plant. (Guiding Price : $100000-150000USD. Different pelletizing solutions are available.) What are the main equipment in the 1-1.2t/hfish pellet production line? The main equipment offish production isfish pellet machine,fish chipper machine,fish Chip Grinder, Rotary Drum Dryer, Counter-Flow Cooler, Packing Machine

This 1-2T/H feed production line or animal feed mill plant contains a feed mixer, feed loader, feed distributor, pellet machine, etc 0086-18037508651 info@hermmachinery.com HERM MACHINERY

.jpg)

Commerical Use Automatic Chicken Feed Pellet Production Line 1-2t/h Animal feed pellet mill machine Line 100~1000KG/H 1-18t/h Ring Die Poultry Feed Machine by Electric 60-1000kg/h Flat Die Poultry Feed Machine by Electric/Diesel Engine

.jpg)

Poultry feed pellet mill is an ideal pelletizing machine for high quality feed pellets. Before pelletizing, grains such as corn, wheat, rice and soybean etc. need to be crushed into powder.

.jpg)

Jul 24, 2020 · After calculation by our engineers, one chicken is calculated with 120g of feed a day, and 150,000 chickens are 18 tons of feed a day, with an average of 1-2t/h feed pellets per hour. Users can consider a 1-2t/h feed pellet machine, or 1-2t/h feed pellet automatic production line equipment. Poultry Farm. 1-2t/h Feed Pellet Machine

This 1-2t/h chicken feed pellets line was built in Uganda. The client had raw materials of maize, soybean, soybean oil meal, sunflower seed oil cakes, pre-mix compound and fish powder. When producing chicken feed pellets, the particle material and powder material are fed into the feed mixer separately: particle materials are conveyed by the

.jpg)

Feed pellet mill is the core equipment of the whole production line. According to different raw material, material formula and working condition, we can offer you different pellet mills. Cooling Process: The feed pellets pressed out by the feed pellet mill are hot and moist. They can’t be crushed, screened or packed immediately. Counter-flow

.jpg)

Mash feed material get into the press area, rollers push the mash into the ring die hole, out be pellet. Pellet feed has many advantages, such as avoid animals being picky, convenient to transportation. Just pellet with high temperature and moisture,need cooling down and remove a part of moisture. Use a fan, cyclone and pipes to wind pellet to

.jpg)

Jul 10, 2020 · For example, the 1-2t/h and 3-5t/h feed pellet machine asked by the customer this time, it is obvious that the tonnage is more than 1 ton, then you can choose the ring die pellet machine. Due to the large tonnage and high production requirements, the ring die pellet machine is more expensive than the general small flat die pellet machine.

Working Process of 1-2t/hfish Pellet Production Line: 1. Raw Materials Preparation:fish pellets can be made from sawdust,fish shavings,fish chips orfish logs, forestry wastes or biomass straws, stalks, etc. 2.fish Crushing System: Crushing machine is used for crushing the larger materials into smaller one.

The main equipment of a complete 1-2 ton per hour feed pellet plant production line includes 37kw hammer mill crusher, 22kw szlh250 1-2 t/h feed pellet mill, single roller double rotary belt mixer, counter-flow feed pellet cooler, crumbler machine, pulse dust collector, vibrating screen, bagging machine, etc.

Model NO.: 1-2T/H Feed Line Type: Forage Equipment Processing Object: Forage, Straw Processing Technics: Crushing-before-Mixing Screen Mesh: With Screen Mesh Grinding Equipment Type: Feed Hammer Mill

Farm Use Feed Pellets Line, Poultry Feed Pellet Production Line, Find Details about Poultry Feed Pellet Production Line, 1.5-2t Poultry Feed Pelleting Mill from Farm Use Feed Pellets Line, Poultry Feed Pellet Production Line - Zhengzhou Leabon Machinery Equipment Co., Ltd.

.jpg)

The 1-2T/H feed pellet production line costs about 10,000-50,000 US dollars. The most critical factor affecting the price of the feed production line is the model (capacity) of the feed pellet machine and the configuration of the pellet machine. If you want to build a small feed processing plant, you can start with a 1-2t/h small feed pellet