.jpg)

Fish feed extrusion is a way to make fish food pellets that are good for fish and easy to digest. This method changes a mix of feed ingredients into dough, which then goes through a machine called an extruder.

.jpg)

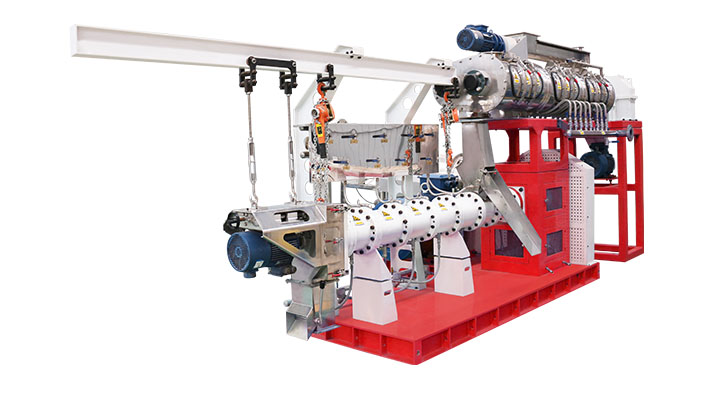

These machines streamline the feed production process, ensuring a consistent and high-quality supply for the extensive aquatic stock. Their capacity to handle large volumes of feed production aligns with the demands of industrial-sized aquaculture enterprises.

.jpg)

With different parameters and feed formulation, fish farmers and feed plants can make floating, sinking, and slow-sinking feed with high quality and nutrition so as to adapt to the diverse ingestion requirements of various aquatic animals.

The selection of appropriate machines, such as pellet mills, extruders, and others, determines the efficiency and quality of fish feed production. By understanding the types, functions, and innovations, producers can optimize their operations and contribute to industry advancement.

Learn about the process of making dry fish feed, the characteristics of floating fish feed pellets, and how to choose the right fish feed extruder machine. Expert guidance awaits!

.jpg)

Various capacities (60kg/h to 2t/h) are available to meet your specific demands, producing kinds of quality feed pellets for aquatic and pet feed. Super automation control, high production efficiency, our fish feed production line is the best choice.

From grinding and mixing to extrusion and pelletizing, our high-quality equipment ensures efficient and consistent fish feed production. Choose our fish feed extruders and machines for reliable performance and high-quality fish feed pellets.