4. Automated Chicken “spare rib” Cutter. Optimize the revenue of your chicken thigh production by value adding your chicken thighs to become high value “snacks”. The Spare-rib cutter is a small, versatile machine with a high capacity, handling a throughput of 100 thighs per minute with only two operators. 5.

.jpg)

The broiler chicken production process begins with the grandparent breeder flocks. The breeder flocks are raised to maturity in grandparent growing and laying farms where fertile eggs are produced. Pullets hatch from the fertile eggs, and they are sent to breeder houses. The pullets produce fertile eggs, which are sent to hatcheries.

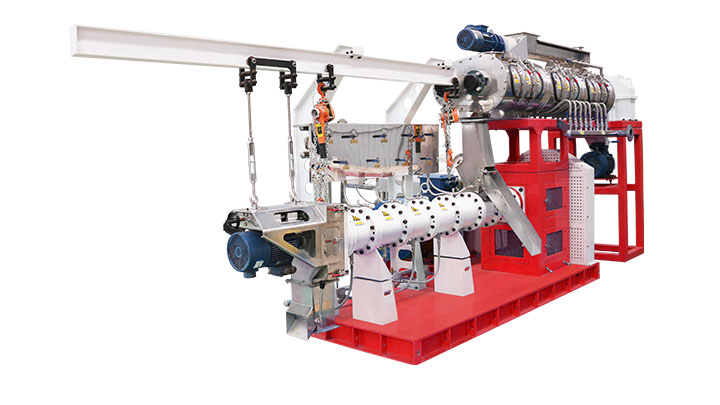

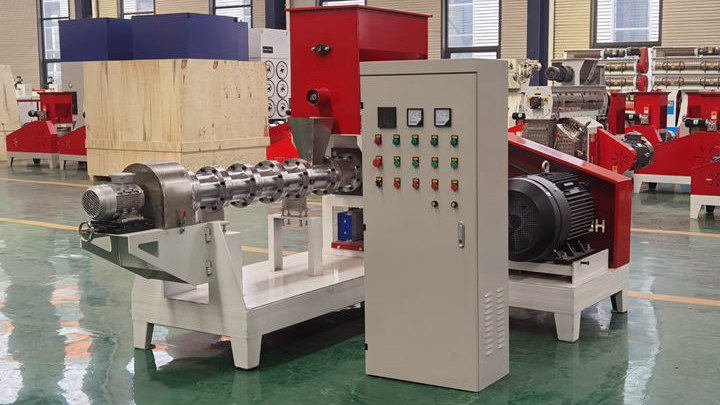

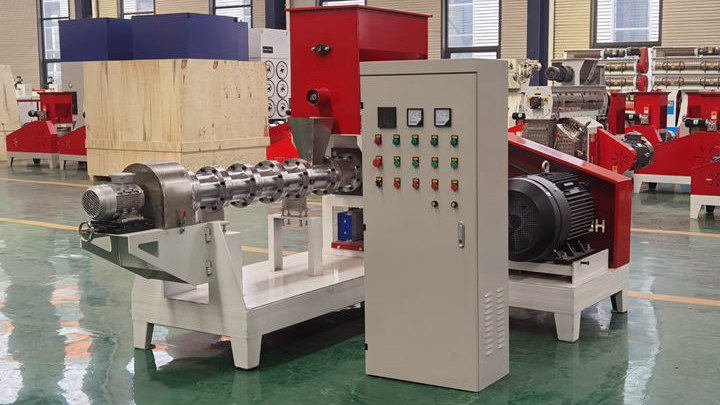

Oct 21, 2019 · Get Price for This Line! Poultry feed production is generally divided into the following steps: receiving and cleaning of feed ingredients, crushing of raw materials, batching, mixing, pelletizing and packaging of finished feed. Raw material cleaning: It is a good production practice to clean poultry feed before starting processing. This cleaning machine can be used to clean the premix at the inlet.

.jpg)

Sammy McKenzie® Chicken Processing Company is a privately owned and managed chicken meat processing business that intends starting small in Santa Fe – New Mexico, but hope to grow big in order to compete favorably with leading chicken meat processing companies in the industry both in the United States and on a global stage.

.jpg)

When it comes to choosing chicken production line, there are several factors that you need to consider. They include the material used in making the equipment, size, capacity, warranty, ease of cleaning, availability of spare parts, and after-sales services. The material used in making the chicken production line is an important consideration. Most of these machines are made of stainless steel because it is strong and durable.

.jpg)

The automatic fish nugget production machine has the characteristics of large production output, easy operation, and cleaning. And this chicken nuggets production line is not only suitable for making chicken nuggets, but it is also suitable for making fish nuggets, hamburger patties, pumpkin pie, potato cakes, and other fried products.

Sep 22, 2020 · For the first week, the temperature should read around 350°C and it will reduce slowly at a rate of 2.80°C per week. This mostly relies on the temperature outside. The litter or bedding of the chicken has to be around 5 to 6 inches in depth. If there is a chance, you can keep some straw in the chicken bed.

A broiler eats about 4.25 kg of feed from day-old to the end of the 8th week. If you multiply that by 100 birds, that would be (4.25kg X 100) = 425 kg or 17 bags of feed for 8 weeks. Therefore you need about 4,250kg or 170 bags of feed for 1000 broiler chickens from day-old until the end of the 8th week.

.jpg)

Chickens are called long-season breeders, meaning that they come into production as days become longer. That is, they start producing eggs when there are more hours of light per day. Typically, day-old chicks are kept on 23 to 24 hours of light per day for the first few days to make sure that they are able to find food and water, especially water.

.jpg)

May 30, 2022 · At the moment, SuperGround is only making small batches of its chicken—20 or 40 pounds at a time—but its production facility has the ability to make more than 400,000 pounds of the mass every

.jpg)

We will design a fully automatic poultry processing production line covering various processes such as slaughter, pre-cooling, segmentation, grading processing, quick freezing, packaging, etc., according to customers' different production needs and pain points, to help customers complete the transformation of production mode, improve production efficiency, and strengthen core competition force.If you want to know more about our flexible processing production line, please feel free to contact us.

The total cost for hiring Business Consultant – $2,500. The total cost for payment of insurance policy covers (general liability, workers’ compensation and property casualty) coverage at a total premium – $9,400. The amount required for the purchase of the first set of chickens – $10,000.

Nov 01, 2020 · Layer Chicken Breeding: These are mainly used for egg production. Broiler Breeding: It is used for chicken meat production. Hatchery: Is for hatching new chicks. Poultry feed: It produce feeds for other poultry farms. You can choose any of them. You can choose breed layer and broiler together if you want to. 4. Specify Poultry Location

Dec 08, 2020 · Blog. Layer poultry farming means raising egg laying poultry birds for the purpose of commercial egg production. Layer chickens are such a special species of hens, which need to be raised from when they are one day old. They start laying eggs commercially from 18-19 weeks of age. They remain laying eggs continuously till their 72-78 weeks of age.

Aug 14, 2022 · On an average, broiler poultry needs about 2.5 square feet space and layer poultry needs about 4 square feet space. For example, if you want to raise 200 layers then you have to ensure about 800 square feet space is available. About 4 square feet space is required per bird in cage system.