.jpg)

All Jones Feed Mills locations now carry a helpful resource manual called "Raising Amazing Chicks- The First Seven Days". This book contains several helpful tips for everything from health to coop management and much more! Even large flocks and experienced poultry producers can learn some new tips and tricks from this handy manual.

A global vision. Today FACCO is the world’s largest producer of modern poultry equipment; it studies, designs and manufactures turnkey technology solutions for eggs and meat production with high quality performance and high standards of health and hygiene, which can be adapted to all climatic conditions on all continents.

Hightop Poultry is not only a poultry farming equipment manufacturer and supplier, but also provides customers with chicken house and poultry farm design for layers and broilers. GET QUOTE Our fully automated poultry farm equipment is only for medium and large chicken farms with 5,000+ birds, If you own a small farm, automatic battery cage system is not cost-effective, you can use our common chicken cage .

.jpg)

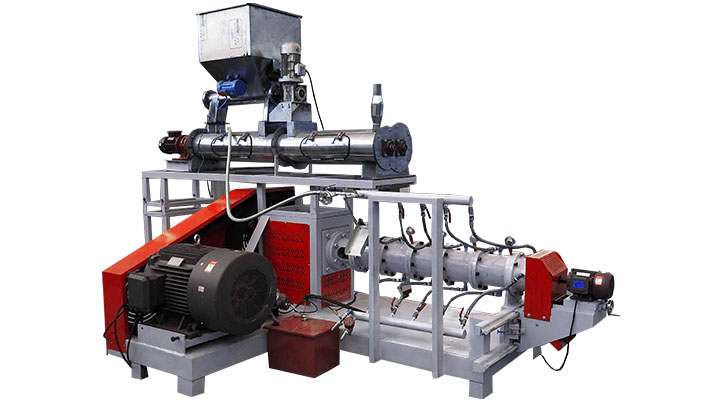

Compared with the same model in the chicken feed making machine industry, the small chicken/poultry feed pellet mill manufactured byLima Machinery has high output, low energy consumption, and the production reached 15-20 kg/kw, while other manufacturers generally reach to 10 kg/kw, unit production energy consumption is generally in 0.05-0.06 degrees / kg.

.jpg)

More and more farmers and investors have begun to purchase poultry feed pellet machines to process and produce feed pellets for setting up a poultry feed mill, poultry feed pellet machines It has become an ideal small-scale feed processing equipment in the minds of farmers and feed manufacturers.

.jpg)

Get Price Now! The process of making chicken pellets for your chicken is simple and it involves: Use a feed hammer mill to grind the ingredients so that they become fine powder ingredients/mashed potatoes. Next, mix all the ingredients in the feed mixer and wait until the mixture is even. The moist viscous mixture shall be the final mixture.

.jpg)

Dec 01, 2012 · Grinding up the feed so the chickens (especially the smaller chicks) can more easily ingest and digest it. There are plenty of grinders out there, but most of them are this type: the huge PTO-driven mixer-grinders for large-scale operations. At a cost of $3000 on up (not including the tractor to power them) this is not a viable option for our farm.

1.1 Chicken Cage Type. Cage types are features of models, capacity, and cage sizes. Two models are the H type battery layer cage and the A-type battery layer cage. These are commonly used for commercial or backyard chicken farms. Chicken capacity is divided into 48, 96, 120, 128, and 160 birds per set.

ABC Machinery is an experienced manufacturer of feed mill machinery. This one of our small feed mill equipment based on flat die design, featured of small size, and high chicken feed production output. Flat die chicken feed mill is more suitable for make your own feed pellets at home or on farm.

.jpg)

Feed Mill Process. The first step in pelleting is conveying of ingredients from bulk silos or godown to the batching bins. It is essential to remove oversize foreign materials and iron trash etc. which otherwise can affect functioning of slide gates, gravity /screw feeder in batching or downstream. Pre-cleaning machines generally include rotary

Feed storage farm silo,also known as feed storage tower,is a kind of feed storage equipment suitable for large and medium-sized chicken farms.The system includes feeding silos or hoppers,conveying PVC pipes,auger or chain discs,discharge ports, silos,feeding sensors and drive motors. The main warehouse adopts 275g/m2 double-sided galvanized

KMEC -- Feed Mill Equipment. KMEC always endeavored to improve the quality of product and aims to meet the new requirements of international market. As a machinery company, it specializes in complete feed machinery, complete compound fertilizer equipments, gasifier equipments for coal (bioenergy, such asfish), pellet press machinery, and

.jpg)

Alibaba offers 361 Chicken Feed Layer Suppliers, and Chicken Feed Layer Manufacturers, Distributors, Factories, Companies. There are 216 OEM, 199 ODM, 43 Self Patent.

feed mill with hammer mill. Productivity: 2 t/h - 5 t/h. Capacity 2t/h: power 25-40 kWt; air consumption for aspiration 2100 cub.m/h; overall dimensions: 18200 x 5000 x 8000 mm Capacity 5t/h: power 72 kWt; air consumption for aspiration 2100 cub.m/h; overall dimensions: 15000 x 10000 x 16000 mm.

In fact, Star Milling was initially purchased by the Cramer family to produce chicken food for their own layer hens for egg production. We’ve learned a lot about nutrition since we first started producing poultry more than 40 years ago. Our drug free feed mill manufactures bulk chicken feed without the use of antibiotics or medications. We believe our Safe Feed/Safe Food Facility, combined with our quality ingredients, is why we offer the best chicken food available.