Jul 21, 2022 · Proveg Engineering & Food Processing Private Limited. Pune, India Gat No.1573, JK Warehouse, Dehu-Alandi Road, Near Omkar Lons, Shelarvasti, Chikhali, 3 Years Member Since : 3 Years 4 Buyer Feedback. View Number. Send Inquiry. Poultry Feed Plant Peanut Sheller Dal Mill Plant Cattle Feed Manufacturing Plant.

.jpg)

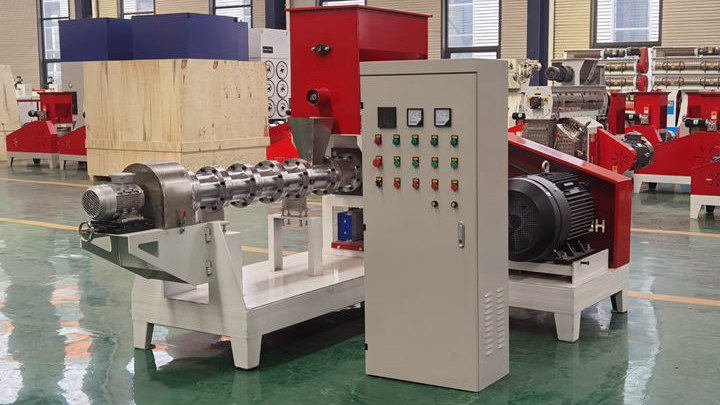

Proveg engineering is the leading manufacturer for cattle & poultry feed making machines and plant. The company is in this business since last 15 years and sucessfully installed many plant in pan india. The company is continuously upgrading the technology as per the demands coming from markets and current trends.

.jpg)

Cattle Feed Processing Systems. Cattle feed is just one of the many animal feeds that are manufactured throughout the world, and can benefit from rotary drying, size reduction, pelleting, cooling, and material handling. Most cattle in the US are on a diet that consists of a multitude of cattle feed options depending on their needs.

.jpg)

Cattle feed making and animal feed processing machinery. The cattle feed is processed and produced in very easy process with help of machinery. The machinery

Project Name: Animal Feed Processing Line. Feed Plant Capacity: 2 ton/hour (2 tons feed pellets can be produced per hour) Application: This feed production line is suitable to process feed pellets for grazing herbivore and ruminate animals such as sheep and cattle. Feed Processing Project with larger Capacity: 5 ton/h Cattle Feed Pellet Plant.

.jpg)

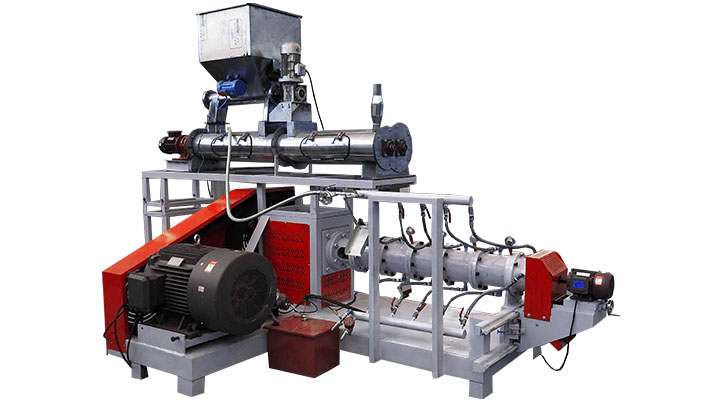

The last thing to do is to package the finished cattle feed pellets. Main cattle feed production machinery. Feed hammer mill, utilized for crushing the raw materials into feed powder. Feed mixer also known as the feed mixing machine, adequately mixes the crushed materials to enhance the uniformity of the constituents. Additionally known as feed pellet mill is the key piece of equipment in this production process.

.jpg)

The machinery you need is determined by the feed you want to produce. Grinder, mixer, pelleting machine, freezer, sifter, weight scale, packaging bags and more are some of the necessary feed processing equipment for starting a complete cattle feed production factory. Here you can see a 3-5 ton/h cattle feed manufacturing process flow chart. This process and layout was designed for one of our clients in Mali, West Africa.

.jpg)

Cattle Feed Processing Machine 14,161 products found from 456 Cattle Feed Processing Machine manufacturers & suppliers. Product List ; Supplier List; View:

Grinder, mixer, pelleting machine, freezer, sifter, weight scale, packaging bags and more are some of the necessary feed processing equipment for starting a complete cattle feed production factory. Here you can see a 3-5 ton/h cattle feed manufacturing process flow chart. This process and layout was designed for one of our clients in Mali, West

.jpg)

Type: ZLSP 150A. Driven by: Diesel Engine. Power: 8Hp. Output: 90-120 kg/h. Weight: 180/220 kg. Package Size: 1000x500x750. Application: Widely used for making poultry, cattle, chicken, fish, forage and other kinds of animal feed pellets. This is a kind of flat die design feed pellet making machine. It is small in size and output (90-120 kg per

.jpg)

From raw material intake to finished feed pellets. ANDRITZ is one of the very few companies with the ability to design, manufacture and supply each and every key processing machine in the feed production line, as well as designing and building the process plant as a whole. Wherever your feed pelleting plant is located and whether you produce

We are China's leading quality Animal Feed Processing Machine manufacturer, supplier in Zhengzhou, Henan, China at latest price. HENAN HUATAI CEREALS AND OILS MACHINERY CO.,LTD. Call : +8618317721166

Operation guidance for using cattle feed pellets making machine. Step 1 Connect the receiving tray with the pellet machine. Step 2 Add gear oil before starting the machine. Step 3 Connect the motor wires of the feed pellet machine. Step 4 Check if the rollers are loose. Step 5 Add materials to make pellets.

Jun 28, 2021 · Processing and the equipment used for both cattle and poultry feed production, the machines or equipment used are: Feed hammer mill: Raw ingredients are passed through the hammer mill, which reduces particle size to the desired size. It is monitored periodically to ensure size uniformity and to help detect wear of hammer mills. It is then stored in the ingredient holding bins. Feed mixer: There are two mixing operations in the feed mixer. One is for the mixing of micronutrients; the

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs