.jpg)

Jan 26, 2020 · As the feed cost represents an high-priced input (~70-80% of broiler production fee), the fowl producer ought to be aware about the dynamics of the feed in its impact on final product amount and quality. If your are a commercial broiler farmer, you must be aware of broiler feed formulation and basics of feed.

.jpg)

Sep 13, 2017 · We provide the 1 ton feed production line solution based on the size of the customer’s poultry feed mill. Advantages of 1 ton Feed production Line. 1)The animal feed pellet line covers little space and is highly-automatized. 2)It can produce smooth and hard pellets which are suitable for all kinds of animals. 3)The pellets are very

.jpg)

Step Three. In this step you, you begin to manage your Broiler’s feeds. In managing the broilers, you should provide disinfectant (Lysol, Lime, Bleaching powder and Phenols) in the entire poultry and it environs to prevent the broilers from contacting poultry disease, also invite a vet doctor to do check ups on broilers.

The poultry feed production team needs to analyze the requirements of the chicken to prepare a proper feed for them.Lima machinery is specialize in designing broiler chicken feed manufacturing process, installation, commissioning and maintaining complete poultry feed mill plant. We also provide customized solutions on feed processing for chicken, cattle, fish, and other livestock animals.

Here is some references for you: For establishing a 1 ton/hour small mash feed or pellet feed production line, the cost is about $14000 ~$15000. For establishing a 2-3 ton/h complete poultry feed production plant which can make both mash feed and pelleted feed, the equipment price and construction cost is about $65000.

We FDSP are manufacturing animal feed production line, poultry feed line, livestock feed plant, chicken feed pellet plant, cattle feed pellet plant, pig feed pellet plant, sheep feed pellet plant etc. ,and our all products have got CE and ISO9001:2000 Certificate. 1.With reasonable technology, high capacity and low energy consumption.

Rice bran 17/35.8 = 47.5%. Soybean meal 18.8/35.8 = 52.5%. So to make 100kg of this broiler feed, we must mix 47.5kg of rice bran with 52.5kg of soybean meal. Example 1. Broiler formulated starter feed for one tonne. The broiler starter feed ingredients are carbohydrates, protein, minerals, and vitamins as listed under the Item column.

.jpg)

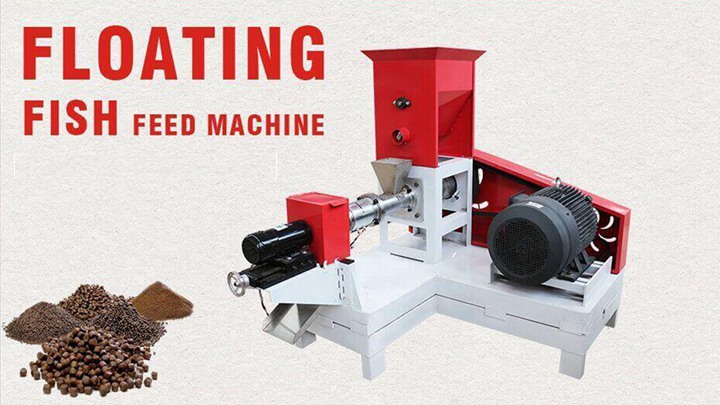

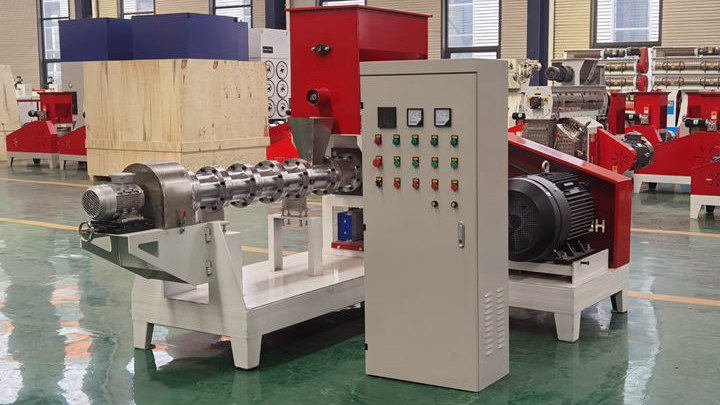

Feed pellet line/plant is also called feed pellet production line. A complete feed mill plant or feed pellet line generally includes silos for raw material storage, raw material receiving system, first batching system, mixing system, second batching, crushing system, pelletizing system, cooling system and bagging system.

Sep 22, 2020 · The term broiler production refers to the rearing of poultry breeds or birds that have a high productivity of meat. Under good management and in the long run, broiler farming is a lucrative business. The broiler chicken is a special species of poultry as it is scientifically made to produce more meat in a very short period of time say 6-9 weeks when they weigh around 6 pounds.

2019/12/11 · Broilers should be ready for slaughter in 5-6weeks with an average weight of 1.8 kg. The feed conversion ratio of most broiler is 1:2 – that is, to get 1 kg of broiler live weight, the farmer needs 2kg of feeds based on prevailing factors.

Most of the modern broilers that producers raise today have a very good feed to meat conversion rate. These birds on average consume about 1.5 kg of feed to produce 1 kg of meat. In the 1980s, it was typical to produce a 2 kg in 70 days. But in 2018, it takes just 20 days to produce a bird of the same weight.

poultry feed production plant for livestock,animal feed processing plant. 1.Animal feed pellet line is a complete set of machines that are specifically used to make feed pellets. 2.The capacity of this poultry feed production plant which can range from 1 ton per hour to 10 tons per hour. 3.Here, you can get specific animal feed pellet plant for

1TPH Small Poultry Feed Pellet Production Line Exported to Chile. Raw Materials: grass, corn, soybeans, other grains, and nutrients, like vitamins, etc.. Diameter of Final Feed Pellets: 2.5/3mm/4mm. Equipment List: grass grinder, mixer, screw conveyor, temporary storage silo, feed pelllet machine, cooler, and finished feed bin, etc. Grass Grinder.

Project Name: Poultry Feed Pellet Production Line. Feed Plant Capacity: 1 ton/hour (1 ton feed pellets cane be produced per hour) Application: It is designed for poultry farm to produce various feed pellets for domestic animals such as duck, chicken, broiler, hen, goose, pigeon, etc. Full View of the Small Feed Plant.

Nov 18, 2017 · Tanzania 1-2T/H Poultry Feed Powder Production Line. Date: Dec 30th,2016. Installation cycle: 10 Days. Sudan 1-2T/H Poultry Feed Pellet Plant. Date: April 24th,2018. Installation cycle: 15 Days. Iraq 1-2T/H Poultry Feed Pellet Production Line. Date: June 28th,2019. Installation cycle: 15 Days. Cape Verde 1-2T/H Poultry Feed Pellet Plant. Date