.jpg)

200kw Livestock Poultry Feed Production Line 10T/H Yield 0.9-10mm Pellet Size.

.jpg)

The 8-10t/h poultry feed plant is a complete set of machines that are specifically used to make feed pellets.This feed production line can make feed pellets for chicken, cattle or other animals using raw materials like corn, soybean, wheat and any other grains. Our poultry feed plant can satisfy your requirements by changing die (mold) and feed

.jpg)

Item307-310 is the cooling system, which bring 3-4% moisture from the feed pellet and make the pellet room temperature. No.501-504: This is final product manual packing section. Final Product. Pellet dia. 6mm-10mm, compress ratio: 1: 5-8. Customized Processing Design According To Your Formula.

Sep 22, 2020 · Two days before bringing the chicks to the firm, you should check the temperature of the broiler house. For the first week, the temperature should read around 350°C and it will reduce slowly at a rate of 2.80°C per week. This mostly relies on the temperature outside.

.jpg)

Oct 21, 2019 · Developing a business plan for your poultry feed production business is critical to determining the long-term viability of the business. The business plan will contain the details of all the feasibility studies you have undertaken to determine the profitability of the business. Challenges You Will Face When Starting a Poultry Feed Mill Business

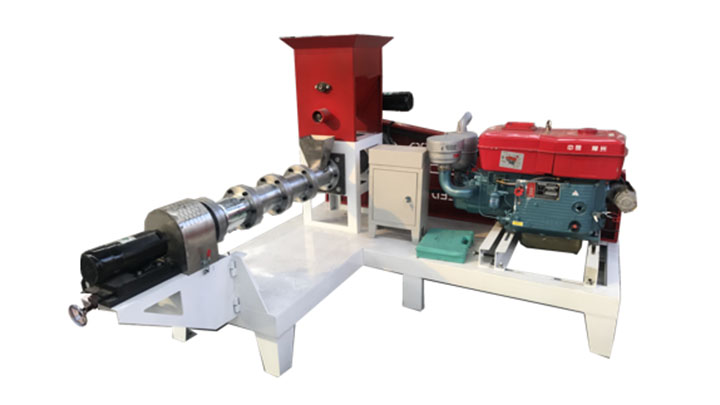

Feed pellet line/plant is also called feed pellet production line. A complete feed mill plant or feed pellet line generally includes silos for raw material storage, raw material receiving system, first batching system, mixing system, second batching, crushing system, pelletizing system, cooling system and bagging system.

poultry feed production plant for livestock,animal feed processing plant. 1.Animal feed pellet line is a complete set of machines that are specifically used to make feed pellets. 2.The capacity of this poultry feed production plant which can range from 1 ton per hour to 10 tons per hour. 3.Here, you can get specific animal feed pellet plant for

.jpg)

2019/12/11 · Broilers should be ready for slaughter in 5-6weeks with an average weight of 1.8 kg. The feed conversion ratio of most broiler is 1:2 – that is, to get 1 kg of broiler live weight, the farmer needs 2kg of feeds based on prevailing factors. Give the birds feeds in bits – possibly every hour and here are some reasons why:

broiler feed line manufacturer/supplier, China broiler feed line manufacturer & factory list, find qualified Chinese broiler feed line manufacturers, suppliers, factories, exporters & wholesalers quickly on LimaFeedPelletizer.com.

.jpg)

High quality Turkey Broiler Poultry Feed Production Line With Siemens Motor Capacity 10T/H from China, China's leading animal feed manufacturing plant product, with strict quality control poultry feed plant machinery factories, producing high quality poultry feed plant machinery products.

All the process above will be controlled and monitored by our advanced computer controlling system. Wide applicable scope: The poultry chicken feed production line can produce both poultry & livestock feed and fish feed and is applicable for medium and small sized feed mills and breeding farms. Centralized control: the analogue panel is adopted.

Home business Small Feed plant poultry feed pellet production line ( 0.8-1.3T/H) · Shandong Double Crane Machinery Manufacture Co., Ltd. US $4000-7500 / LEARN MORE 2,633 Poultry Feed Machine from 561 Suppliers - Global Sources

.jpg)

Most of the modern broilers that producers raise today have a very good feed to meat conversion rate. These birds on average consume about 1.5 kg of feed to produce 1 kg of meat. In the 1980s, it was typical to produce a 2 kg in 70 days. But in 2018, it takes just 20 days to produce a bird of the same weight.

All you need to start is a good one-positioning and government-approved facilities, stable grain supply, and of course, knowledge of operating the business. It must be pointed out that this business cannot be obsolete because it plays an important role in the poultry farming industry. According to the scale you want to start, the start-up