.jpg)

GSmach supply turn-key solutions with our twin screw extrusion machine to your compounding projects, including material handling, dosing, extrusion, pelletizing and other aspects. 跳至内容 +86 15312989585

Single screw extruders are simpler, more affordable, and suitable for basic PVC pipe production with granulated materials. They offer easier maintenance and operation. Twin screw extruders, on the other hand, provide better mixing, higher efficiency, and are suitable for more complex materials, including PVC powder.

Aug 20, 2023 · Twin-screw extruders are slightly more expensive due to their greater processing power and adaptability. Choosing the right type of machine needs to be determined by your specific application needs, which will have a direct impact on the cost of your investment.

.jpg)

Nov 30, 2023 · Given these advantages, modular twin-screw extruder designs have gained considerable traction in the plastics processing industry, further underscoring the importance of twin-screw extrusion technology. Lab-scale twin screw extruders. Lab-scale twin screw extruders serve a crucial role in the research and development (R&D) phase of plastic

Co-rotating, intermeshing twin screw extruder: The co-rotating twin screw extruder is the most prevalent continuous mixing device in the world. Typical applications include masterbatch and compounding processes in which fillers, pigments, dyes and additives are homogeneously mixed into the plastic matrix.

.jpg)

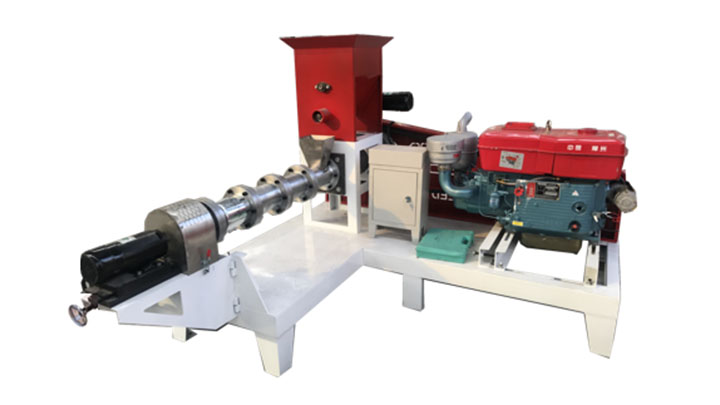

Your Premier Twin Screw Extruder Manufacturer. Benk twin screw extruder also named conical twin screw extruder which is used to make PVC profile, PVC pipe, PVC foam board, PVC marble sheet and PVC pellets, WPC profiles, and so on, but twin screw extruder need work with different downstream machines in the whole production line.

.jpg)

Bausano is an expert plastic extrusion manufacturer, producing a fully customizable range of plastic extruders for a variety of sizes, applications and materials. From a lab scale extruder up to industrial production capacity with Single and Twin-screw extruders, we provide every kind of bespoke extruders tailored to your needs.

.jpg)

Several factors can affect the cost of a PVC cable extrusion machine: Machine Type: Twin screw extruders tend to be more expensive than single screw extruders. Output Capacity: Machines with higher production capacities are usually more costly. Features: Machines with advanced features like automation or unique cooling systems may cost more.

Leading the way in extrusion technology, we offer unparalleled expertise, quality and value. Established in 1983, Century Extrusion offers twin screw extruder parts and highly engineered twin screw extrusion systems covering different levels of extruders, from entry level to high level specifications for various customer requirements, as well

Dec 1, 2023 · Twin-screw extruders also have significant applications in the food industry. They are used in processes like cooking, forming, texturizing, and cooling to produce various food products. For example, twin-screw extruders are commonly used in the production of breakfast cereals, snack foods, pet foods, and confectionery products.

Apr 28, 2024 · Types of Screw Design (Single Screw, Twin Screw): A single-screw extruder may be used over a twin-screw one depending on its application needs; mixing capability is improved by the latter as well as the venting ability and handling complex property materials, while single screws are known for their simplicity in use coupled with cost-effectiveness.

.jpg)

Apr 20, 2021 · Nanjing Haoxiang Machinery Manufacturing Co., Ltd: Customized service, personalized production, years of experience and professional twin screw extruder manufacturer. We have strong technical team, skilled workers, strict quality control system to offer excellent quality products which has been praised by all customers.

Jan 17, 2024 · Single Screw Extruder VS Twin Screw Extruder. Extruders are versatile machines and are central to the plastics industry due to their ability to produce a wide range of products with different shapes and sizes. They are used in the production of items like plastic films for packaging, window frames, plastic sheets, and insulation for electrical

Dec 1, 2023 · Twin-Screw Extruders: These machines, equipped with two screws, offer more control and versatility in the extrusion process. They excel in handling a more comprehensive range of materials, including heat-sensitive, abrasive, or materials that require high levels of mixing.

.jpg)

Sep 14, 2023 · Twin screw extruders also offer better control over residence time and temperature, enabling more precise processing of sensitive materials. Twin Screw Extruder Elements. The twin screw extruder machine is a complex piece of equipment with several key components that contribute to its efficient operation and performance.