.jpg)

We, the trusted Pellet Feed Machine Supplier in Bangladesh, New Delhi, Delhi, Gujarat, Ahmedabad, Rajkot, Jammu, Srinagar, Jharkhand, and Ranchi offer various pellet machine models to suit your specific production needs and budget. They produce consistent, high-quality pellets that are easy for animals to digest and absorb nutrients.

One Stop Feed Mill Solution. We are the exclusive distributor of world renowned manufacturers of feed processing machinery in Bangladesh. We provide Turnkey feed mill plant for breeder feed, boiler feed, layer feed, sinking fish feed, floating fish feed, shrimp feed, cattle feed and TMR feed.

.jpg)

Mini Cattle Feed Machine. Rs 35,000/ Piece. Automatic Cattle Feed Machine. Rs 80,000/ Piece. Ring Die Cattle Feed Pellet Making Machine. Rs 45,000/ Piece. Animal Feed Pallet Machine. Rs 35,000/ Piece. Feed Mixer Machine.

Manufacturer of Honey Processing Machine - Honey Processing Plant With Moisture Reduction Unit, Honey Processing Plant, Small Scale Honey Processing Machine and 200 Kg Honey Processing Machine With Vacuum Evaporation offered by Ylem Energy, New Delhi, Delhi.

Aug 31, 2022 · Rupsi Feed Mill, owned by City Group, one of the largest industrial groups in Bangladesh, has officially come into production. On this occasion, the Ambassador of the Netherlands appointed in Dhaka visited the Rupsi Feed Mill located in the City Economic Zone of Narayanganj.

.jpg)

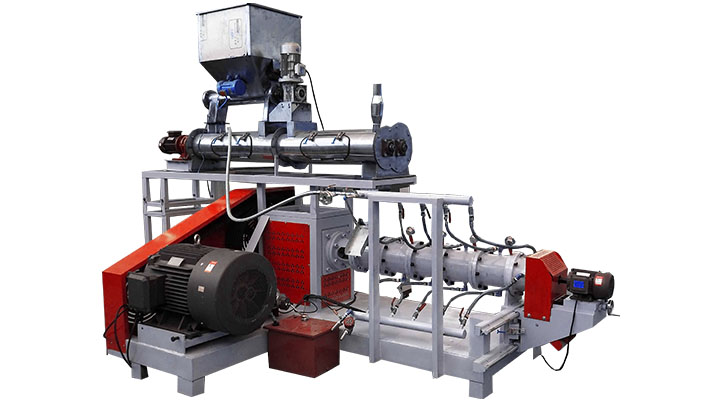

Floating Fish Feed Extruder Machine 3-4T/H. Floating Fish Feed Pellet Making Machine 4-5T/H. Floating Fish Feed Pellet Mill 6-7T/H. Fish Feed Pellet Extruder 8-10T/H. Floating Fish Pellet Machine For Sale 10-12T/H. Sinking Fish Feed Machine. Menu Toggle. Fish Feed Processing Line. Sinking Fish Feed Pellet Mill 0.6-1.2T/H.

.jpg)

This chaff cutter and grain crusher is a new type of feed processing machine which combines chopping, rubbing, crushing and beating. 2. Straw cutter not only can smash dry or green corn stalks, sorghum stalks, peanut vine, sweet potato pods, various pastures but also can crush grain, corn for feeding animals, which is favorable for improving the digestion and absorption of

.jpg)

Jul 15, 2024 · In 2019, City Group Bangladesh sought to undertake a major extension of its feedmill, which was built in 2003, with an initial capacity of 20 tons/hour. The extension was to build a new massive 111 tons/hour feedmill, including reusing existing machines across nine lines.

.jpg)

Poultry & Fish Feeds manufacturing and supplier company in Bangladesh. Customized products available as per customers requirements. Brand Name : Adorsho Feed. Address : House 2/2, Block # A, Iqbal road, Mohammadpur, Dhaka – 1207, Bangladesh. Phone : +88 01718 659376

We can arrange to set up various kinds of feed mill machines depending on the type of your feed mill. And you will get your desired feed plant machinery at reasonable prices. Whether you want to initiate a poultry feed mill, fish feed mill, or cattle feed mill; CAPTAINS GROUP got you covered.

.jpg)

We are the exclusive distributor of world renowned manufacturers of feed processing machinery in Bangladesh. We provide Turnkey feed mill plant for breeder feed, boiler feed, layer feed, sinking fish feed, floating fish feed, shrimp feed, cattle feed and TMR feed.

Buy Cattle Feed Pellet Plant in Bangladesh. Leader Machine Tools is the best Cattle Feed Pellet Plant Manufacturers in Bangladesh. Suppliers and Exporters. Get best products at reasonable prices.

.jpg)

Jun 08, 2017 · considering the average cost of the concentrated feed as Rs. 8.17/Kg, a 13.0% saving in the consumption of concentrated feed due to Azolla supplementation ultimately leads to a feed cost saving of 10.0 paise/day/bird and hence a layer unit maintaining 10,000 birds could cut down its expense towards feed to a tune of

Floating fish food production line shrimp feed making machine. FOB Price: 30000 - 30000 USD / Sets Applicable Industries Manufacturing Plant, Food & Beverage Factory ; Showroom Location Ukraine, Sri Lanka, Bangladesh

.jpg)

Here, we provide a hammer grinding machine – fish feed hammer mill for processing feed stuffs of various granularity into small pieces. And here is the working principle of this machine: hammer hit breaks raw materials in the crushing chamber with high-speed rotation; then the broken materials move with continuous friction and crash against the hammer, toothed plate and sieve for crushing.