.jpg)

As a professional feed factory machines manufacturer, RICHI’s goal is to be the best in our industry, with high customer satisfaction, solution-oriented, sustainable and attainable targets, and to become a leading global brand by adopting a quality, solid production and service approach, and by offering advanced technology machines to the market.

.jpg)

May 10, 2022 · Understanding how these pellet making machines perform will help you make a better decision about which machine to buy for your operation. Flat Die Pellet Making Machine. Flat die pellet making machine is a kind of new type of pellet making machine that can produce various kinds of granulated materials. It has the characteristics of simple

.jpg)

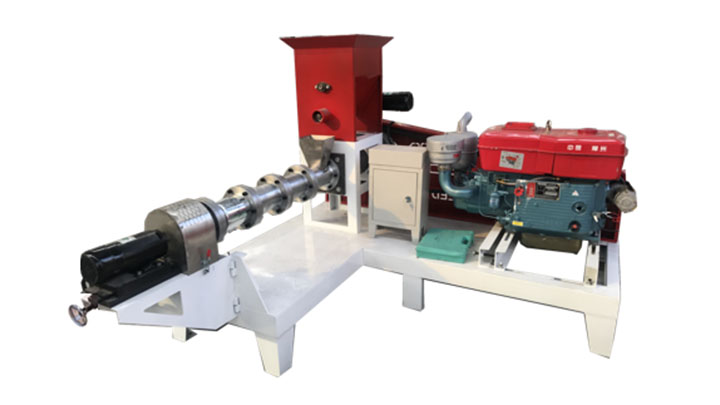

Step 1: Selection of the Pellet Machine. The first thing first, you must have a high-quality pellet machine. When it comes to purchasing a pellet mill, there are two options: Ring Die Pellet Machine and Flat Die Pellet Mill. The Flat Die Pellet Machine is a lightweight, compact-sizefish pellet making machine used for home use.

.jpg)

Our floating fish feed pellet mill production capacity covers 40kg to 1000kg per hour. In addition to stand-alone machines, we are also good at designing and integrating complete fish food production lines with flexible configurations.

.jpg)

Feed pellet machine small dry and wet straw crushing granulator pelletizer machine feed pellet maker ₱20,510 9. 11kw Pellet Press Animal Feed Pellet Mill Biomass pelletizer machine 200kg/h-300kg/h 500kg/h-600kg/ ₱20,600

.jpg)

We have been having intermittent phone issues. Please call or text 715-829-5432 if you have problems. PelletMasters Pellet Mills, Hammer Mills, and Fine Grinders

.jpg)

The pelletizing machine market size crossed USD 2.9 billion in 2023 and is projected to record over 3.8% CAGR between 2024 and 2032, driven by the expanding livestock industrys demand for high-quality, pelletized feed due to its nutritional benefits and ease of handling.

.jpg)

Choose the right pellet mill for you. Learn more about our brand-new innovative Pellet Mill, now available in 4 sizes. Make pellets out of a wide range of materials using our industrial-grade pellet making systems.

Your Livestock Farming with Premium Feed Machinery Welcome to our one-stop shop for top-of-the-line feed machinery tailored to enhance the productivity and success of your livestock farming operations.[ecae_button] Our carefully curated selection offers a range of high-quality pellet machines, powerful shredders, and efficient feed systems designed to meet the unique needs of various livestock

.jpg)

From pellet machine to full pellet production plants, RICHI's industry-leading fully scalable modular systems provide you advantages and solutions to bring your process technology to market and commercialization quickly, safely and on budget.

Choosing the right feed pellet mill can seem daunting, but our expertise and guidance can help you make the right decision with confidence.Lima Machinery has years of experience in designing and manufacturing feed pellet mills that meet the highest quality standards, and we can help you choose the best machine for your feed production needs.

Pelletizing machine price philippines ranges between $7,,000 and $100,000. We providefish pellet line, feed pellet line, inquire now.

Jul 9, 2015 · Quick access to the pellet mill chamber allows faster die and roller changes for more time in production. The compact design of the flat die pellet mill means that small, lightweight models are available, which are more suitable for small-scale production. Another key advantage of the flat die pellet mill is visibility.

Our pellet mills are built to the highest possible standards and designed to make your job easier, safer, and more efficient—and deliver you the best possible pellet. With robust reliability and ease of operation, your CPM pellet mill is backed by the best service and support teams in the animal feed, oilseed, andfish pellet maker industries.

Sep 3, 2024 · Definition and Function of a Pelletizer Machine. Pelletizer machines generally reduce or compress the materials into small and even pellets. As the name suggests, the pelletizing machine uses mechanical attributes to achieve the purpose and usually forces the input substance against discs or rollers that create heat, which helps squeeze the particles together.