.jpg)

Jan 17, 2024 · Basic Working Principle of Plastic Extruder Machine. The fundamental operation of a plastic extruder machine involves heating, melting, and shaping thermoplastic materials. Typically starting with granular or pelletized raw materials, the extruder heats, mixes, and pushes the material through a die, forming a continuous profile.

.jpg)

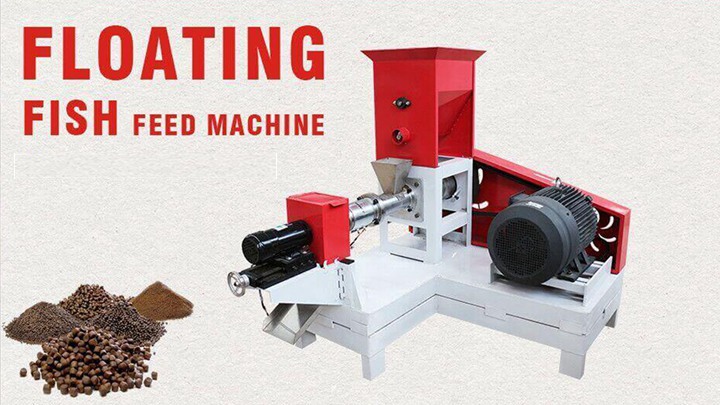

1.5-2T/H extruder machine for fish feed. The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity.

desertcart ships the plastic extruder parts in Curepipe, Port Louis, Quartier Militaire, Centre de Flacq, Port Mathurin and more cities in Mauritius. Get unlimited free shipping in 164+ countries with desertcart Plus membership.

ANDRITZ offers unique, high-capacity extrusion lines for the production of all kinds of feed for fish and shell fish. The ANDRITZ extruders ensure that the feed has the right physical properties – giving it the correct sinking attributes according to where in the water the feed should be accessed.

.jpg)

ANDRITZ Feed & Biofuel is well known as a worldwide supplier of performance parts for OEM extru-ders and is your partner for the li-fetime of your equipment; whether that equipment was initially sup-plied by ANDRITZ or by another ma-nufacturer. Over 30 years experience in the ext-rusion industry for use in the produc-

.jpg)

We are the Top 5 Plastic Extruder Machine Manufacturer in China, Professional Customized Twin Screw Extruder & Triple Screw Extruder etc, Provide solutions such as Color Masterbatch, Biodegradable Plastics, Engineering Plastics, PET recycling, PET & PLA sheet etc

The ANDRITZ single-screw extruder type EX1021 represents state-of-the art technology, ensuring unique quality feed at minimum operating costs.

Since 2006 we have been pushing our way up successfully, as a leading manufacturer and service provider of wear parts for twin-screw extruders. With a lot of care, passion and even more knowledge. A golden extruder rule: it all comes out in the end. At Extruder Experts, we don’t screw it up. Our strict quality management takes care of that.

.jpg)

We supply new and used plastic extruders to satisfy a wide variety of manufacturing needs. We work closely with our customers to help them identify the best extruder for their product and production needs, and help them make the most cost-effective, high value purchase available.

Function: fish feed processing. Capacity:120kg/hour, 200kg/hour, 500kg/hour, Model: AVN65, AVN70, AVN85 Category: Fish food extruder machine line

Low-End Fish Feed Pellet Extruder. Cost: The price for basic fish feed making machine in Ghana ranges from $1,000 to $5,000. Features: These feed pellet machine often come with limited functionalities and lower production capacities. High-End Fish Feed Pellet Extruder. Cost: Advanced fish feed machine models in Ghana can cost anywhere between

.jpg)

TWO STAGE EXTRUDER. Combine the high speed and extensive mixing of twin screw processing and the low speed, low temperature, and low shear of single screw processing. Ideal for compounding of heat- and shear-sensitive materials PVC compounds for cable, shoe sole, transparent container, and medical applications EVA shield cable compounds.

.jpg)

For example, a basic single screw extruder can range from $10,000 to $50,000, whereas twin screw extruders can cost up to $400,000. Aside from the machine’s specifications, the brand also affects the cost. Established brands known for their quality and service might offer their machines at a premium.

.jpg)

Have something you need to get to Mauritius? This can be an urgent spare part, new machinery or equipment, PPE or any specialised product not locally available, Let Supply Webb handle everything for you including; sourcing, custom's compliance, insurance, export, import, clearance, forex and freight.

Nov 1, 2013 · Here’s a great low cost filament extruder solution. It uses basic parts available from any hardware store, and a few 3D printed ones — estimated cost is well under $100. It’s very