.jpg)

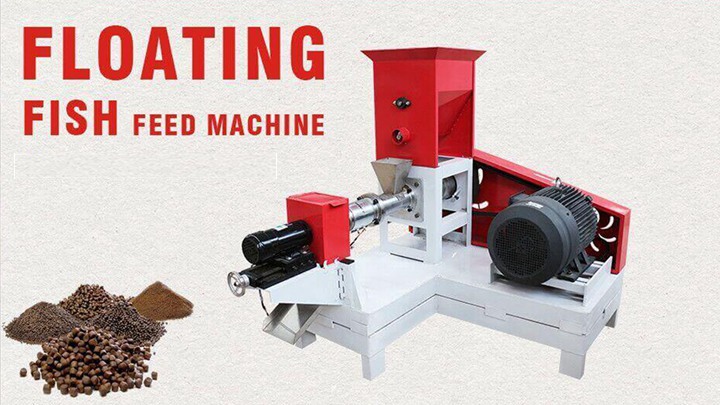

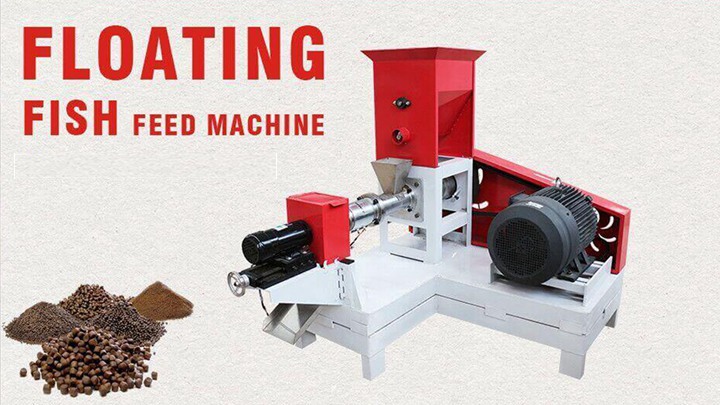

We offer a versatile ULTRA extruder machine with top-of-the-line parts, innovative systems and base, highly customizable product options, and user-accessible extruders that are efficient and with safety features built right in.

Factors Affecting Fish Feed Extruder Machine Prices. Capacity and Size: The size of the extruder directly correlates with its capacity, which can range from small-scale machines suitable for local fish farms to large-scale machines designed for commercial production.

.jpg)

Consider Used Machines. For many, the cost of a brand-new feed pellet machine in Algeria can be prohibitively expensive. In such cases, opting for a used machine can be a wise decision: Quality Check: Ensure the used machine is in good working condition. Ask for maintenance records and, if possible, a demonstration to see the machine in action.

High-End Fish Feed Pellet Extruder. Cost: Advanced fish feed machine models in Ghana can cost anywhere between $10,000 and $20,000. Features: These versions offer higher production capabilities and often include automated systems for better efficiency. Factors Influencing Cost of Fish Feed Pellet Extruder Brand Reputation

Find Professional Suppliers to get higher Quality of feed machinery and reducing production Cost we have special consultant for ring die design based on various of feed formulations . better holes arrangement and more quntity to improve die performance . also special material 48mn shells will last longer life spam .

.jpg)

Our multifunctional PolyTwin, EcoTwin and CompacTwin twin-screw extruders offer flexible, reliable 24/7 processing for your breakfast cereals, food ingredients, pet food and aqua feed products. The interior of the barrel is extremely resistant to wear, extending its operating lifetime.

.jpg)

China Extruder Machine wholesale - Select 2024 high quality Extruder Machine products in best price from certified Chinese Plastic Machine manufacturers, Plastic Machinery suppliers, wholesalers and factory on LimaFeedPelletizer.com

.jpg)

We are the Top 5 Plastic Extruder Machine Manufacturer in China, Professional Customized Twin Screw Extruder & Triple Screw Extruder etc, Provide solutions such as Color Masterbatch, Biodegradable Plastics, Engineering Plastics, PET recycling, PET & PLA sheet etc

.jpg)

Dec 1, 2021 · The machine's performance was evaluated with constant feed moisture, constant feed rate, and constant screw speed, while the multi-channel dies were varied for 2, 4, 6, and 8 mm.

.jpg)

Aug 3, 2022 · The gearbox is the core component of the extruder, which is the heart of the extruder and the quality is related to the life of the entire extruder. For a high-quality gearbox, the gears and shafts must firstly be processed by a high-precision machining centre (CNC), and then be ground by a gear grinder after heat treatment, the precision of

Jan 17, 2024 · Basic Working Principle of Plastic Extruder Machine. The fundamental operation of a plastic extruder machine involves heating, melting, and shaping thermoplastic materials. Typically starting with granular or pelletized raw materials, the extruder heats, mixes, and pushes the material through a die, forming a continuous profile.

.jpg)

Jun 08, 2017 · considering the average cost of the concentrated feed as Rs. 8.17/Kg, a 13.0% saving in the consumption of concentrated feed due to Azolla supplementation ultimately leads to a feed cost saving of 10.0 paise/day/bird and hence a layer unit maintaining 10,000 birds could cut down its expense towards feed to a tune of

.jpg)

The fish feed making machine market aligns closely with this demand, as these machines enable efficient and customized feed production. Growth Trends and Future Projections The trajectory for the fish feed making machines in the Philippines looks promising.

For those keen on procuring a feed pellet machine in Botswana, numerous “for sale” options are available. From brand-new machines with the latest technology to more affordable second-hand options, there’s something for every budget. The Future: Feed Production Line and Plants