.jpg)

2-4TPH poultry feed mill equipment in Uzbekistan. Project Name : poultry feed mill equipment Capacity : 2-4 ton /h (equal to 12,000 -24,000 tons per year) Application : Used to manufacturing feed, animal feed production Install Country : Uzbekistan

.jpg)

By Pak Agro Engineers, 3 years ago. Feed Grinder Machine . Standard Size. Feed Grinder Machine 8” X 14” Description: Production Capacity: 2,000 Kg/H To 2,400 Kg/H Power: 10 Hp Speed: 1800 rpm Warranty: Six Months Guarantee: No Vibration, Smooth Performance, No Heating Problem Weight: 120 Kg Color: Royal Green, SP.

STLP 300 and STLP400 animal feed pellet machine is a small poultry feed production line (600~1000kg/h), which includes system of grinding, mixing, conveying, pelletizing and cooling. The diameter of final feed pellets can be 2~8mm. It is a multifunction poultry feed pellet making machine which is suitable for processing feed pellets for various

Given that cattle, buffalos, cows and bulls all have diverse nutrition requirements, feed composition will contrast based on the type of livestock animal. The only constant is that the feed must be rich in energy, protein, and fiber. Setting up a animal feed processing plant can complete make high quality feed pellets for animal growth.

.jpg)

Additive feed : Amino acid, vitamin, antibiotic, antioxidant, etc. The small cattle feed plant cost is closely related to the production output, process design and equipments included in the plant. The equipment cost is about 10,000 ~ 17,000 USD. Jsut feel free to get in touch with us for FREE Quotation List, and get other details of our cattle

poultry feed production plant for livestock,animal feed processing plant. 1.Animal feed pellet line is a complete set of machines that are specifically used to make feed pellets. 2.The capacity of this poultry feed production plant which can range from 1 ton per hour to 10 tons per hour. 3.Here, you can get specific animal feed pellet plant for

.jpg)

Characteristics of animal feed production line. Customizable design for the whole plant. For different materials, depending on your specific needs or budget, we can add or remove some machines. Wide capacity range. Its processing power ranges from 1t/h to 20t/h. If you have more production needs, we can also customize for you.

1 ton/h feed milling machine. $10,000~$20,000. 3 ton/h animal feed process company (both making mash feed and pelleted feed) $60,000. 5 ton/h cattle feed process line. $70,000~$80,000. 10 ton/h feed manufacturing plant. over $100,000. Note: When it comes to project investment cost, you need to consider raw materials, workshop rent, equipment

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features Press Copyright Contact us Creators

From receiving of raw materials and ingredients through processing and packaging equipment, blending, and warehousing, we take great measures in our design and build, processes, and equipment selection to ensure that your needs are met. Safety in all aspects of feed production is integral in what we do. Whether it is in our construction design

.jpg)

Modular plant engineering: from small plants to industrial animal feed factories. Thanks to our well-designed concepts, AWILA® animal feed plants are highly user-friendly and offer extremely efficient use of raw materials. This has been the case for over 100 years. Our plants are known for delivering maximum economic benefits through efficient

.jpg)

3. Equipment and Personnel. The investment animal feed production business plan will focus on the plant and equipment as the biggest expenditure in the initial costs, you need to invest in high quality equipment to achieve quality feeds. You could also invest in customized equipment for your needs which will call for more investment, use expert

.jpg)

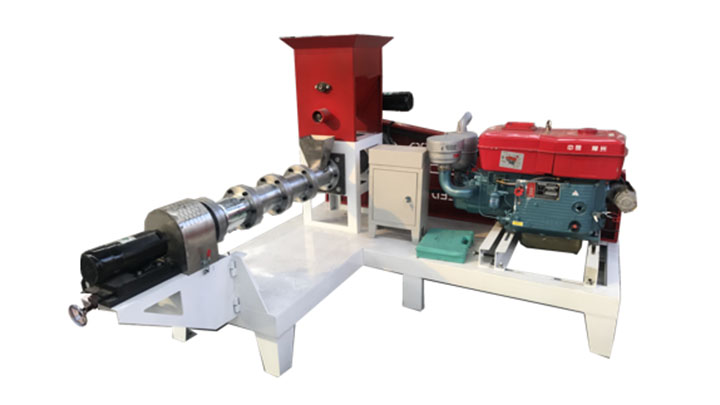

Fish, Poultry & Animal Feed Mill Plant. We are the leading name in the field of designing, manufacturing and installation of Horizontal and Vertical type Feed Mill Plant such as Animal feed plants, Cattle feed plants, Poultry / Chicken feed plants, Fish and Pig feed plants. Our plants, simple in structure, easy in operation and service, safe in solidity, small in volume and light in weight.

Jun 08, 2007 · Grinding of Feedstuffs. Grinding is a major function of feed manufacturing and is by far the most common method of feed processing. It is also the most cheapest and simple process and results in a substantial reduction in particle size and exposure of much more surface area to action of chemicals as well as to the digestive juices.

Cattle and Chicken Feed Mill Plant Setup in Uzbekistan [Project Report] This animal feed processing plant, ordered by a customer from Uzbekistan, was designed to produce cattle feed pellets and poultry feed pellets. The capacity is up to 4 tons per day. Our engineers have rich experiences in overseas installation and commissioning.