.jpg)

The floating fish feed extruder allows for precise control over the pellet’s size, shape, density, and nutritional composition, ensuring that the fish receive a balanced and high-quality diet for optimal growth and health. This technology is crucial in the aquaculture industry, where efficiently producing nutritious and cost-effective fish

.jpg)

Clextral extrusion systems efficiently produce high-energy feed with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility. Extruded feeds are produced to match fish feeding habits (floating, neutral buoyancy or sinking) to energize feeding and reduce waste.

.jpg)

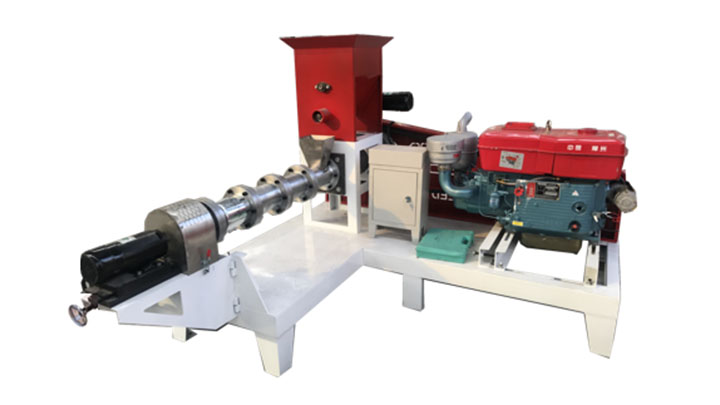

The floating fish feed machine is to convert soybean meal, rice bran, fish meal, bone meal, corn meal, flour, etc. into fish feed pellets with various shapes by heating and extruding. It has a capacity of 40-350kg/h, even bigger.

The RCPH120*2 extruder machine for fish feed is mainly used for the 1.5-2t/h production and processing of various floating aquatic feeds. The new type conditioner can soften material fibers, improve gelatinization degree, reduce power consumption and increase production capacity.

.jpg)

A floating fish feed extruder machine is a piece of equipment used in the production of floating fish feed pellets for aquaculture. Floating fish feed is designed to float on the water’s surface, making it easily accessible to the fish being raised.

.jpg)

The fish feed extrusion process consists of several steps: Ingredient Selection: The first step involves sourcing the best quality raw materials like fishmeal, grains, and oils. Grinding: The ingredients are then finely ground to ensure uniformity. Mixing: Ground ingredients are mixed together in a feed mixer machine.

Apr 24, 2024 · 1. Extruder: The extruder is the heart of the floating fish feed making machine. It processes the raw materials, typically a mixture of grains, proteins, fats, vitamins, and minerals, into a dough-like consistency. Through heat, pressure, and mechanical action, the extruder cooks the ingredients and forms them into uniform pellets.